In the ever-evolving landscape of energy infrastructure, the choice of materials plays a crucial role in determining the success and longevity of pipeline projects. Among the various options available, API 5L ERW (Electric Resistance Welded) pipe has emerged as a popular choice for many engineers and project managers. This article explores the three key benefits of using API 5L ERW pipe in pipeline projects, focusing on efficiency, sustainability, and cost-effectiveness.

|

|

|

API 5L ERW Pipe: Pipeline Construction Efficiency

When it comes to pipeline construction, efficiency is paramount. API 5L ERW pipe offers several advantages that contribute to streamlined project execution and improved overall efficiency.

Firstly, the manufacturing process allows for rapid production rates. The electric resistance welding technique used in creating these pipes is a continuous process, enabling manufacturers to produce long lengths of pipe quickly and consistently. This increased production speed translates to shorter lead times for project managers, reducing potential delays in construction schedules.

Moreover, the uniformity and consistency of API 5L ERW pipes contribute significantly to installation efficiency. These pipes are manufactured to tight tolerances, ensuring that each section fits seamlessly with the next. This precision reduces the need for on-site adjustments and modifications, speeding up the installation process and minimizing the risk of errors.

The lightweight nature of API 5L ERW pipes, compared to some alternative materials, also enhances efficiency during transportation and handling. Lighter pipes are easier to move and position, reducing the need for heavy machinery and potentially lowering transportation costs. This characteristic is particularly beneficial in remote or challenging terrains where access for large equipment might be limited.

Additionally, the welding process used in ERW pipe production creates a strong, reliable joint that requires minimal additional processing on-site. This reduces the time and resources needed for field welding, further accelerating the construction process.

By combining these efficiency-enhancing features, API 5L ERW pipes contribute to faster project completion times, reduced labor costs, and improved overall project economics. This efficiency is not just about speed; it's about optimizing resources and minimizing disruptions, which is crucial in today's fast-paced and competitive energy sector.

Sustainability and API 5L ERW Pipe: A Green Choice for Pipelines

In an era where environmental considerations are at the forefront of industrial decisions, the sustainability aspects of API 5L ERW pipe make it an attractive option for pipeline projects.

One of the primary sustainability benefits of API 5L ERW pipe lies in its production process. The electric resistance welding technique used in manufacturing these pipes is generally more energy-efficient compared to some other pipe production methods. This reduced energy consumption translates to a lower carbon footprint for the production phase, aligning with global efforts to minimize industrial emissions.

Furthermore, the durability and corrosion resistance of ERW pipes contribute to their sustainability profile. These pipes are designed to withstand harsh environmental conditions and resist corrosion, leading to extended service life. Longer-lasting infrastructure means less frequent need for replacement, reducing the overall material consumption and associated environmental impacts over time.

Their material efficiency is another sustainability advantage. The manufacturing process allows for precise control over wall thickness, ensuring that material is used optimally without excess. This efficient use of raw materials not only reduces waste but also contributes to resource conservation.

In terms of recyclability, API 5L ERW pipes fare well. At the end of their service life, these steel pipes can be fully recycled, contributing to the circular economy. The ability to recycle and repurpose the material reduces the demand for virgin resources and minimizes waste sent to landfills.

By choosing API 5L ERW pipes for pipeline projects, companies can demonstrate their commitment to sustainable practices. This choice aligns with environmental, social, and governance (ESG) criteria that are increasingly important to stakeholders, including investors, regulators, and the public.

Balancing Cost and Performance in Energy Projects

In the competitive landscape of energy projects, finding the right balance between cost and performance is crucial. API 5L ERW pipe offers a compelling solution that addresses both these aspects effectively.

From a cost perspective, API 5L pipes present several advantages. The manufacturing process is generally more cost-effective compared to some alternative pipe production methods. The continuous nature of electric resistance welding allows for higher production rates, which can lead to economies of scale and lower per-unit costs.

In terms of installation costs, the uniformity and consistency of API 5L ERW pipes can lead to significant savings. The reduced need for on-site adjustments and the ease of joining pipes can lower labor costs and shorten project timelines. This not only reduces direct expenses but also minimizes the indirect costs associated with prolonged construction periods.

While cost-effectiveness is a key advantage, it does not come at the expense of performance. API 5L pipes are known for their reliability and durability. The electric resistance welding process creates a strong, continuous weld seam that can withstand high pressures and various environmental stresses. This reliability translates to reduced maintenance needs and lower lifecycle costs.

The versatility of API 5L pipes further enhances their cost-performance ratio. These pipes are available in a wide range of sizes and grades, allowing project managers to select the most appropriate specifications for their specific needs. This flexibility ensures that projects can optimize their pipe choices without over-engineering or compromising on essential requirements.

Contact Longma Group

API 5L pipe stands out as a versatile and valuable solution for modern pipeline projects. Its ability to enhance construction efficiency, contribute to sustainability goals, and offer a balanced approach to cost and performance makes it an attractive choice for a wide range of applications in the energy sector.

As the industry continues to evolve, with increasing emphasis on efficiency, environmental responsibility, and cost-effectiveness, the role of 5L ERW pipe is likely to grow. Project managers and engineers who leverage the benefits of this piping solution can position their projects for success in an increasingly competitive and environmentally conscious market.

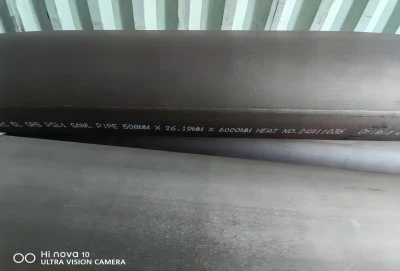

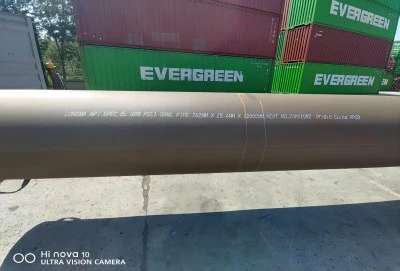

For those considering ERW pipe for their upcoming pipeline projects, it's crucial to partner with a reputable manufacturer who can provide high-quality products that meet specific project requirements. Longma Group is a leading API 5L ERW Pipe manufacturer, offering a wide range of grades (B, X42, X46, X52, X56, X60, X65, X70, X80) and levels (PSL1, PSL2). With outer diameters ranging from 1/4" to 20" and thicknesses from SCH10 to SCH160, Longma Group can cater to diverse project needs. Their commitment to quality is evidenced by their API 5L, ISO, and QMS certifications. For more information or to discuss your specific pipeline requirements, please contact Longma Group at info@longma-group.com. Their team is dedicated to providing excellent products and services to ensure the success of your pipeline projects.