In the world of pipeline infrastructure, the quality and performance of line pipes are paramount. The American Petroleum Institute (API) has set the gold standard for line pipe specifications with API 5L, ensuring that pipelines meet the highest standards of safety, durability, and efficiency. This article delves into the key benefits of API line pipe manufactured to API 5L specifications, exploring how this standard transforms pipeline infrastructure and delivers exceptional performance.

|

|

|

Safety and Reliability

One of the most significant advantages of API line pipe manufactured to API 5L specifications is the enhanced safety and reliability it offers. The API 5L standard sets stringent requirements for the manufacturing process, material composition, and testing procedures of line pipes. This rigorous approach ensures that pipes can withstand the demanding conditions of modern pipeline operations.

API 5L specification covers various grades of steel, from the basic Grade B to high-strength grades like X80. Each grade is designed to meet specific performance requirements, allowing engineers to select the most appropriate pipe for their project's needs. The standard also defines two product specification levels (PSL 1 and PSL 2), with PSL 2 having more stringent requirements for chemical composition, tensile properties, and non-destructive examination.

The enhanced safety features of API line pipe include:

- Improved resistance to internal and external pressures

- Better performance under extreme temperature conditions

- Enhanced corrosion resistance

- Greater resistance to stress cracking and fatigue

These features collectively contribute to a safer pipeline infrastructure, reducing the risk of leaks, ruptures, and other potentially catastrophic failures. By adhering to API 5L specifications, manufacturers ensure that their line pipes meet the highest standards of safety and reliability, providing peace of mind to pipeline operators and the communities they serve.

Superior Mechanical Properties and Performance

API line pipe manufactured to API 5L specifications boasts superior mechanical properties that translate into exceptional performance in the field. The standard sets precise requirements for tensile strength, yield strength, and elongation, ensuring that pipes can handle the stresses and strains of pipeline operations without compromising their integrity.

Some key mechanical properties of API 5L line pipes include:

- High tensile strength: API 5L pipes can withstand significant longitudinal stresses without failure.

- Excellent yield strength: These pipes resist permanent deformation under load, maintaining their shape and structural integrity.

- Optimal elongation: API 5L pipes exhibit good ductility, allowing for some deformation without fracture.

- Controlled hardness: The standard ensures that pipes are not too brittle, reducing the risk of cracking during installation or operation.

These superior mechanical properties result in line pipes that deliver outstanding performance across various applications. Whether used in oil and gas transportation, water distribution, or other industrial pipelines, API line pipe consistently meets and often exceeds performance expectations.

The API 5L specification also addresses the pipe body, weld seam (for welded pipes), and heat-affected zone properties. This comprehensive approach ensures that every part of the pipe meets the required performance standards, eliminating weak points that could compromise the pipeline's integrity.

Furthermore, the standard's emphasis on consistent quality means that pipeline operators can rely on uniform performance across their entire pipeline network. This consistency simplifies maintenance, reduces the risk of localized failures, and contributes to the overall longevity and efficiency of the pipeline infrastructure.

Cost-Effectiveness and Long-Term Value

While the initial cost of API line pipe manufactured to API 5L specifications may be higher than that of non-certified alternatives, the long-term value proposition is compelling. The superior quality and performance of these pipes translate into significant cost savings over the lifecycle of a pipeline project.

Key factors contributing to the cost-effectiveness of API 5L line pipes include:

- Reduced maintenance requirements: The high quality and durability of API 5L pipes mean less frequent repairs and replacements.

- Lower risk of failures: By minimizing the likelihood of leaks and ruptures, API 5L pipes help avoid costly shutdowns and environmental remediation efforts.

- Extended service life: The superior corrosion resistance and mechanical properties of these pipes contribute to a longer operational lifespan.

- Improved operational efficiency: The consistent quality of API 5L pipes allows for more predictable and efficient pipeline operations.

Moreover, the API 5L specification's emphasis on standardization facilitates easier sourcing and interchangeability of components. This standardization can lead to more competitive pricing and reduced inventory costs for pipeline operators.

The cost-effectiveness of API 5L line pipes extends beyond direct financial benefits. By ensuring higher safety standards and environmental protection, these pipes help companies meet regulatory requirements and maintain their social license to operate. This aspect is increasingly important in today's environmentally conscious business landscape.

Additionally, the API 5L specification's recognition and acceptance worldwide make it easier for companies to participate in international projects. This global compatibility can open up new business opportunities and facilitate smoother project execution across borders.

API Line Pipe Manufacturer

The API 5L specification has set a new benchmark for line pipe performance, delivering unparalleled safety, superior mechanical properties, and long-term cost-effectiveness. By adhering to these rigorous standards, pipe manufacturers are playing a crucial role in transforming pipeline infrastructure worldwide.

As the demands on pipeline systems continue to grow, the importance of high-quality, reliable line pipes cannot be overstated. API 5L line pipes offer the perfect blend of performance, safety, and value, making them the ideal choice for modern pipeline projects across various industries.

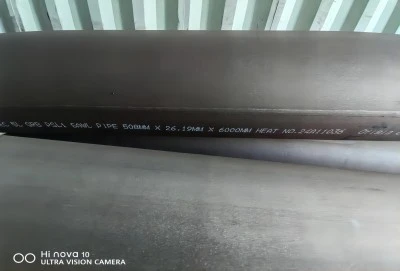

For those seeking to elevate their pipeline infrastructure, choosing line pipe manufactured to API 5L specifications is a decision that pays dividends in safety, performance, and long-term value. Longma Group is a leading API line pipe manufacturer, offering a wide range of products that meet API 5L specifications. Our product line includes grades from B to X80, PSL1 and PSL2 levels, with outer diameters ranging from 1/8" to 80" and thicknesses from SCH10 to SCH160. With the fastest delivery time of 7 days and relevant certifications including API 5L, ISO, and QMS, we are committed to providing excellent products and services to meet your pipeline needs. For more information or to discuss your specific requirements, please contact us at info@longma-group.com. Let us help you build a safer, more efficient, and more reliable pipeline infrastructure for the future.