3PE pipes represent a significant advancement in pipeline technology, combining superior corrosion protection with mechanical durability. These specialized pipes serve critical roles in various industries, particularly in oil and gas transportation infrastructure. Understanding their composition, properties, and applications helps engineers and industry professionals make informed decisions about pipeline systems and infrastructure development. The increasing global demand for efficient and durable pipeline solutions has led to continuous improvements in 3PE pipe technology.

|

|

|

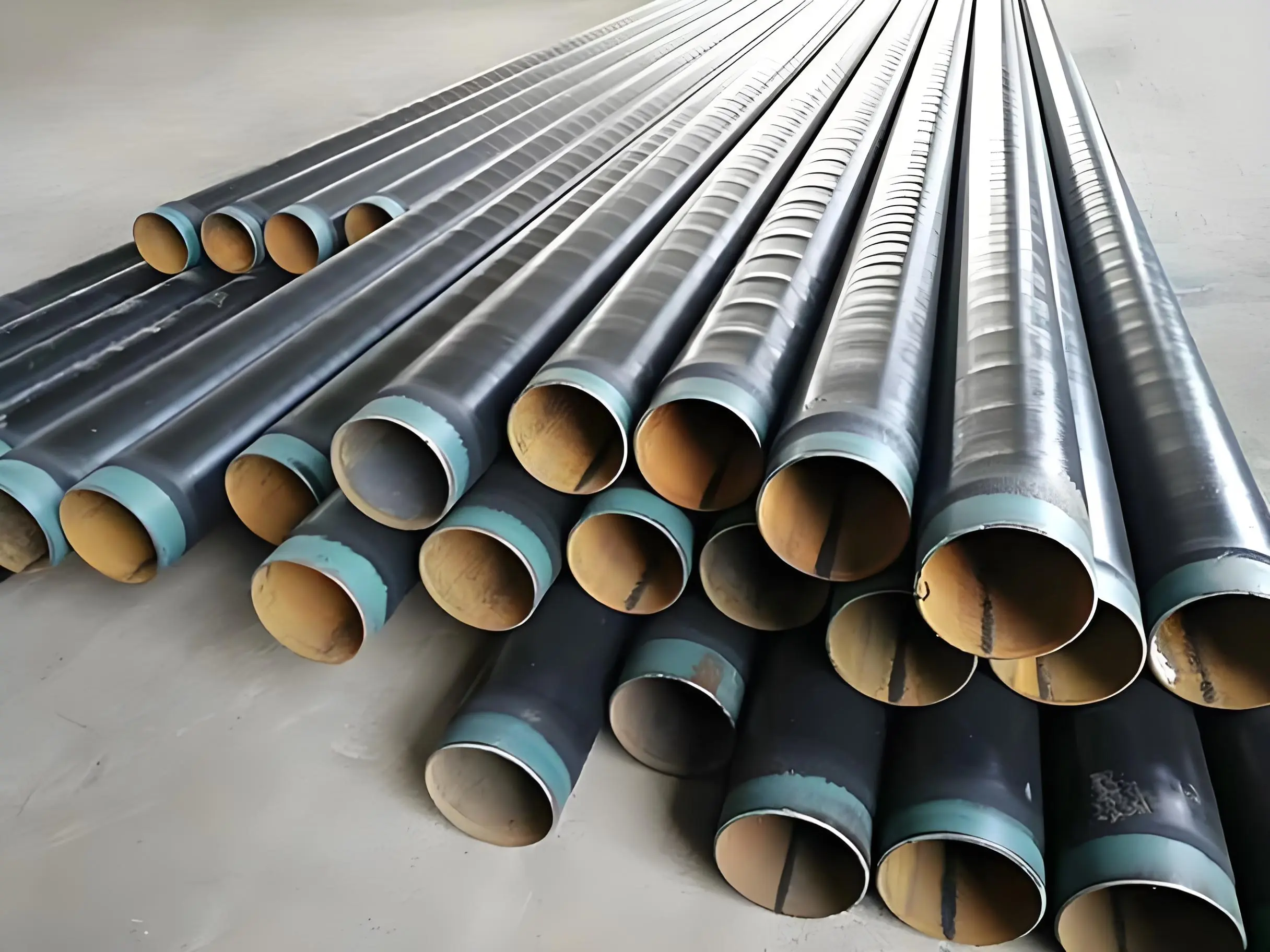

3PE: Three-layer polyethylene-coated External Anti-Corrosion Steel Pipe

The foundation of 3PE pipe technology begins with high-quality steel pipe cores. These base materials undergo rigorous manufacturing processes to ensure structural integrity and performance standards. Seamless steel pipes, produced through sophisticated extrusion processes, offer uniform strength characteristics essential for high-pressure applications. The manufacturing process eliminates potential weak points associated with welded seams, making them ideal for critical applications where reliability is paramount.

Spiral steel pipes, crafted through helical welding techniques, provide excellent structural stability and cost-effectiveness for large-diameter applications. The spiral welding process allows for efficient material usage and creates pipes with superior resistance to external pressures. These pipes often find applications in water transmission, oil transportation, and natural gas distribution systems where large diameters are required.

Straight seam steel pipes, manufactured using longitudinal welding methods, complete the range of base material options. These pipes undergo sophisticated welding procedures utilizing advanced automation and quality control systems. The welding process includes multiple inspection stages, including radiographic testing and ultrasonic examination, to ensure weld integrity.

Surface preparation represents a critical phase in the manufacturing process. The steel surface undergoes comprehensive cleaning procedures, including degreasing, chemical cleaning, and abrasive blasting. The blast cleaning process typically achieves a surface profile of 50-100 micrometers, creating optimal conditions for coating adhesion. Quality control measures during surface preparation include regular surface profile measurements and cleanliness assessments.

Three-Layer Structure

The sophisticated 3PE pipes are a meticulously designed solution for protecting steel pipes, ensuring long-term durability and performance in demanding environments. Each layer in this system plays a distinct and complementary role, contributing to the overall effectiveness of the coating in safeguarding pipelines from corrosion, mechanical damage, and environmental stresses.

The fusion-bonded epoxy (FBE) primer layer forms the foundation of the coating system, delivering outstanding corrosion protection through its exceptional barrier properties. This epoxy layer exhibits excellent adhesion to the steel surface, creating a tightly bonded protective shield. The application process begins by thoroughly cleaning the steel pipe using abrasive blasting to achieve the required surface profile and cleanliness. The pipe is then heated to temperatures ranging from 180°C to 250°C. At this stage, an electrostatically charged epoxy powder is applied, which melts and fuses with the heated surface. The high-temperature application ensures complete cross-linking of the epoxy molecules, creating a durable, uniform coating with superior resistance to moisture, chemicals, and cathodic disbondment. This layer acts as the first line of defense, significantly reducing the risk of underfilm corrosion and enhancing the pipe's lifespan.

The middle adhesive layer serves as a critical intermediary, ensuring the cohesion and stability of the entire coating system. Composed of specially formulated modified polyethylene copolymers, this layer establishes a strong chemical and mechanical bond between the FBE primer and the outer polyethylene layer. One of its primary functions is to accommodate the varying thermal expansion coefficients of the adjacent layers, preventing delamination or coating separation under fluctuating temperatures. The adhesive layer's effectiveness is further enhanced by advanced formulations that incorporate compatibilizers and coupling agents, which improve interlayer adhesion. These specialized additives ensure that the adhesive layer maintains its integrity, even under extreme thermal cycling or mechanical stresses, contributing to the overall reliability of the coating system.

The outer polyethylene layer provides robust mechanical protection and shields the pipeline from environmental challenges, including physical impacts, abrasion, and exposure to UV radiation. Typically made from high-density polyethylene (HDPE), this layer is engineered for superior toughness and flexibility. HDPE materials used in this context are enriched with UV stabilizers, antioxidants, and other performance-enhancing additives, ensuring long-term resistance to degradation caused by sunlight, oxidation, and other environmental factors. The thickness of the polyethylene layer is carefully tailored to meet specific operational needs. For instance, pipelines operating in severe service conditions, such as rocky terrain or underwater environments, may require an increased layer thickness to provide additional mechanical reinforcement. This outermost layer also helps the pipeline withstand soil stresses and prevents damage during transportation and installation.

Good Corrosion Resistance

The exceptional performance characteristics of 3PE pipes have revolutionized pipeline protection in the oil industry. Laboratory and field testing demonstrate outstanding resistance to cathodic disbondment, with typical values showing less than 5mm radius disbondment after 28 days of testing at 65°C. This superior performance ensures long-term coating integrity in cathodically protected pipeline systems.

The coating system exhibits remarkable resistance to soil stress and chemical exposure. Impact resistance testing shows exceptional results, with many systems exceeding 10 J/mm of coating thickness at ambient temperatures. The coating maintains flexibility at low temperatures while providing adequate hardness and abrasion resistance at elevated temperatures. Thermal aging studies indicate coating stability for service lives exceeding 50 years under normal operating conditions.

Water vapor transmission resistance represents another crucial performance attribute. Advanced testing methodologies show extremely low permeation rates, typically below 0.1 g/m²/day at 23°C. This exceptional barrier property prevents moisture-related corrosion issues and extends pipeline service life. The coating system also demonstrates excellent resistance to soil bacteria and chemical agents commonly encountered in underground environments.

Wholesale 3PE Pipe Manufacturers

Leading 3PE pipe manufacturers employ state-of-the-art production facilities equipped with advanced coating application systems. LONGMA GROUP maintains comprehensive quality management systems certified to international standards. Their production lines incorporate automated controls for critical parameters including temperature profiles, coating thickness, and cooling rates. Regular calibration and maintenance programs ensure consistent product quality.

Quality control procedures include continuous monitoring of coating application parameters and regular testing of finished products. Testing protocols encompass holiday detection, adhesion testing, impact resistance evaluation, and coating thickness measurements. Environmental controls within production facilities maintain optimal conditions for coating application and curing. Documentation systems ensure complete traceability of materials and process parameters.

Product packaging and handling procedures receive careful attention to maintain coating integrity. LONGMA GROUP utilizes specialized handling equipment and storage systems designed to prevent coating damage. Their packaging options include reinforced wooden boxes, custom-designed pallets, and protective end caps. Export packaging meets international standards for maritime transport and long-term storage. The company provides comprehensive handling and storage guidelines to ensure proper product care throughout the supply chain. If you are choosing your 3PE pipe manufacturers, welcome to contact LONGMA GROUP at info@longma-group.com.