When it comes to selecting the ideal steel pipe for your project, understanding the differences between A500 and A53 steel pipe is crucial. A53 pipe, known for its versatility and strength, is a popular choice in various industries. However, A500 steel also offers unique advantages. This comprehensive guide will help you navigate the key differences, applications, and cost considerations of these two steel types, enabling you to make an informed decision for your specific needs.

|

|

|

Strength and Durability: A500 vs A53

Comparing Yield Strengths of A500 and A53 Steel Pipes

The yield strength of steel pipes plays a vital role in determining their performance under stress. A500 steel pipes typically boast higher yield strengths compared to A53 pipes. Grade B A500 steel offers a minimum yield strength of 46,000 psi, while Grade B A53 steel provides a minimum yield strength of 35,000 psi. This difference is significant in applications where structural integrity is paramount.

However, it's important to note that A53 pipes are available in different grades, including Grade A and Grade B. Grade B A53 steel pipes offer improved mechanical properties compared to Grade A, making them suitable for a wider range of applications. The choice between A500 and A53 pipes often depends on the specific project requirements and load-bearing needs.

Impact of Wall Thickness on Pipe Performance

Wall thickness is another crucial factor affecting pipe performance. A500 steel pipes are typically available in various wall thicknesses, allowing for greater flexibility in design and application. The thicker walls of A500 pipes contribute to their higher strength and durability, making them ideal for structural applications.

A53 steel pipes, while generally having thinner walls, offer excellent performance in fluid transmission applications. The wall thickness of A53 pipes is often specified by schedule numbers, with Schedule 40 and Schedule 80 being common choices. The appropriate wall thickness depends on factors such as internal pressure, external loads, and corrosion allowance.

Weldability and Structural Integrity Considerations

Both A500 and A53 steel pipes exhibit good weldability, but there are some differences to consider. A500 steel pipes, due to their higher carbon content, may require preheating before welding to prevent cracking. On the other hand, A53 pipes generally have lower carbon content, making them easier to weld without preheating.

Structural integrity is a critical factor in many applications. A500 steel pipes, with their higher yield strength and thicker walls, often provide superior structural integrity in load-bearing applications. A53 steel pipes, while not as strong as A500, offer excellent structural integrity for their intended applications, particularly in fluid transmission systems.

Applications: Where Each Steel Excels

A500 Steel: Ideal for Heavy-Duty Construction ProjectsA500 steel pipes shine in heavy-duty construction projects where strength and durability are paramount. Their high yield strength and thick walls make them excellent choices for structural applications such as:

- Building columns and support beams

- Bridge construction

- Industrial frameworks

- Heavy equipment manufacturing

In these applications, A500 steel pipes provide the necessary load-bearing capacity and resistance to deformation under stress. Their superior strength-to-weight ratio allows for efficient material use, potentially reducing overall project costs.

A53 Steel: Versatile for Pressure and Non-Pressure Uses

A53 steel pipes offer versatility that makes them suitable for a wide range of applications, both in pressure and non-pressure systems. Some common uses include:

- Water supply systems

- Natural gas distribution

- Fire sprinkler systems

- Low-pressure steam lines

- Structural support in light-duty applications

The ability of A53 steel pipes to handle various fluids and gases, coupled with their good corrosion resistance, makes them a popular choice in plumbing and HVAC systems. Their lower cost compared to A500 pipes also contributes to their widespread use in less demanding structural applications.

Industry-Specific Applications: Oil, Gas, and Beyond

In the oil and gas industry, both A500 and A53 steel pipes find important roles. A53 pipes are commonly used in oil and gas pipelines due to their pressure-bearing capabilities and resistance to corrosion. They're particularly well-suited for transporting crude oil, natural gas, and refined petroleum products.

A500 steel pipes, while less common in fluid transmission, play crucial roles in offshore platform construction and other heavy-duty applications within the oil and gas sector. Their high strength makes them ideal for structural components that must withstand harsh marine environments and extreme loads.

Beyond oil and gas, both types of steel pipes find applications in various industries:

- Chemical processing plants

- Power generation facilities

- Agricultural irrigation systems

- Mining operations

- Automotive manufacturing

The choice between A500 and A53 steel pipes in these industries depends on factors such as required strength, pressure ratings, and cost considerations.

Cost-Effectiveness: Choosing the Right Pipe

Initial Costs vs. Long-Term Value of A500 and A53 PipesWhen considering the cost-effectiveness of A500 and A53 steel pipes, it's essential to look beyond the initial purchase price. A53 pipes generally have a lower upfront cost, making them attractive for projects with tight budgets or where high strength is not a primary requirement.

A500 steel pipes, while typically more expensive initially, can offer better long-term value in certain applications. Their higher strength and durability may result in:

- Reduced material usage in structural applications

- Lower frequency of repairs or replacements

- Improved safety margins in critical structures

The long-term cost-effectiveness depends on factors such as project lifespan, load requirements, and environmental conditions. A thorough lifecycle cost analysis can help determine which option provides the best value for a specific project.

Maintenance and Replacement Considerations

Maintenance needs and replacement frequency significantly impact the overall cost of using steel pipes. A53 steel pipes, particularly those used in fluid transmission systems, may require regular inspections and maintenance to prevent corrosion and ensure optimal performance. The cost of these ongoing activities should be factored into the long-term budget.

A500 steel pipes, due to their higher strength and typically thicker walls, may offer longer service life in certain applications. This can translate to reduced replacement frequency and lower long-term costs. However, proper maintenance is still crucial to maximize the lifespan of both A500 and A53 pipes.

Balancing Project Requirements with Budget Constraints

Choosing between A500 and A53 steel pipes often involves balancing project requirements with budget constraints. Key considerations include:

- Required strength and load-bearing capacity

- Pressure ratings for fluid transmission applications

- Corrosion resistance needs

- Expected service life of the structure or system

- Available budget for initial purchase and ongoing maintenance

In some cases, a hybrid approach using both A500 and A53 steel pipes in different parts of a project may provide the best balance of performance and cost-effectiveness. Consulting with experienced engineers and suppliers can help optimize pipe selection based on specific project needs and budget limitations.

The choice between A500 and A53 steel pipes depends on your project's specific requirements. A500 steel excels in heavy-duty structural applications, offering high strength and durability. A53 pipes provide versatility and cost-effectiveness for a wide range of pressure and non-pressure uses. Consider factors such as strength requirements, application specifics, and long-term cost implications when making your decision. By carefully evaluating these aspects, you can select the steel pipe that best meets your project needs while optimizing performance and cost-effectiveness.

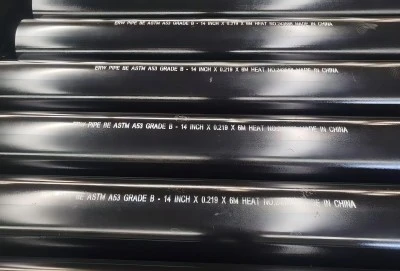

A53 Steel Pipe For Sale

Hebei Longma Group offers high-quality A53 pipes for various applications. Our state-of-the-art production facilities, imported from Germany, ensure top-notch quality and consistency. With over 300 skilled employees, including 60+ technical experts, we deliver superior products backed by extensive industry knowledge. Our comprehensive testing facilities, including ultrasonic flaw detectors and X-ray equipment, guarantee the integrity of every pipe we produce. We pride ourselves on fast delivery, with standard thickness pipes ready in as little as 7 days. Our products are certified by API 5L, ISO 9001, ISO 14001, and more, meeting international quality standards. Thanks to our efficient production model and strong supplier relationships, we offer competitive pricing without compromising on quality.

To explore our A500 and A53 steel pipe offerings or to discuss your project requirements, reach out to our sales team. We're committed to providing not just products, but solutions that drive your project's success. Contact us at info@longma-group.com to learn more about how we can meet your steel pipe needs.