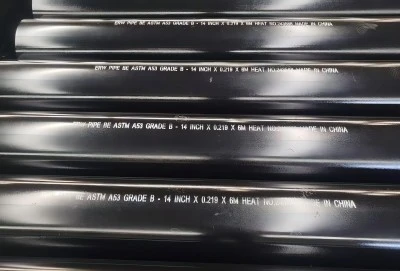

When it comes to industrial piping systems, A53 Grade B pipes are a popular choice due to their versatility and reliability. These pipes, commonly referred to as a53 gr.b pipes, are widely used in various applications, including water and gas transmission, construction, and general engineering purposes. Understanding the dimensions, standard sizes, and tolerances of these pipes is crucial for engineers, contractors, and project managers to ensure proper selection and installation. In this comprehensive guide, we'll delve into the specifics of A53 Grade B pipe dimensions, exploring standard measurements, tolerances, and common size ranges for both seamless and welded varieties.

|

|

|

Standard Dimensions and Wall Thickness of A53 Grade B Pipes

A53 Grade B pipes are manufactured according to the ASTM A53 standard, which specifies the requirements for seamless and welded carbon steel pipe. These pipes are available in a wide range of sizes to accommodate various project needs. The standard dimensions of a53 gr.b pipes are typically expressed in terms of nominal pipe size (NPS), outside diameter (OD), and wall thickness.

The nominal pipe size is a dimensionless designator that roughly corresponds to the inner diameter of the pipe. However, it's important to note that the actual inner diameter may differ from the nominal size. The outside diameter of A53 Grade B pipes remains constant for a given nominal size, while the wall thickness can vary depending on the schedule or weight class of the pipe.

Wall thickness is a critical factor in determining the pipe's pressure-bearing capacity and overall strength. A53 Grade B pipes are available in various schedules, with Schedule 40 and Schedule 80 being the most common. The schedule number refers to a standardized system that defines the relationship between the pipe's nominal size, outside diameter, and wall thickness.

For example, a 4-inch NPS A53 Grade B pipe with Schedule 40 would have an outside diameter of 4.5 inches and a wall thickness of 0.237 inches. The same 4-inch NPS pipe in Schedule 80 would maintain the 4.5-inch outside diameter but have a thicker wall at 0.337 inches.

It's worth noting that a53 gr.b pipes are also available in other schedules and weight classes, such as Standard (STD), Extra Strong (XS), and Double Extra Strong (XXS), each offering different wall thicknesses to suit specific application requirements.

Tolerances and Dimensional Requirements Under ASTM A53

The ASTM A53 standard sets forth specific tolerances and dimensional requirements for A53 Grade B pipes to ensure consistency and reliability in manufacturing. These tolerances cover various aspects of the pipe's dimensions, including outside diameter, wall thickness, and length.

1.Outside Diameter Tolerances:

For a53 gr.b pipes with NPS 1-1/2 and smaller, the tolerance on the outside diameter is ±0.015 inch. For pipes NPS 2 and larger, the tolerance is ±1% of the specified outside diameter. This allowance ensures that pipes can be properly fitted with standard connectors and fittings.

2.Wall Thickness Tolerances:

The wall thickness of A53 Grade B pipes is subject to both over and under tolerances. For seamless pipes, the wall thickness at any point shall not be more than 12.5% under the nominal wall thickness specified. For welded pipes, this under tolerance is set at 8% of the nominal wall thickness. Over tolerances are not limited unless a maximum is specified in the purchase order.

3.Length Tolerances:

A53 Grade B pipes are typically supplied in random lengths, usually between 16 and 22 feet. When specific lengths are required, the standard allows for a tolerance of ±1/2 inch for lengths up to 30 feet, and ±3/4 inch for lengths over 30 feet.

4.Straightness:

The ASTM A53 standard also specifies requirements for pipe straightness. For pipes 1-1/4 inches NPS and larger, the maximum deviation from a straight line shall not exceed 0.030 inch times the number of feet of total length divided by 22.

These tolerances are crucial for ensuring that a53 gr.b pipes meet the necessary quality standards and can be reliably used in various applications. Adherence to these dimensional requirements helps maintain the integrity of piping systems and ensures proper fit and function in assemblies.

Common Size Ranges for Seamless and Welded A53 Grade B Pipes

A53 Grade B pipes are available in a wide range of sizes to accommodate diverse project requirements. The size ranges differ slightly between seamless and welded pipes, with each type offering unique advantages for specific applications.

1.Seamless A53 Grade B Pipes:

Seamless pipes are manufactured without a welded seam, offering superior strength and reliability for high-pressure applications. Common size ranges for seamless a53 gr.b pipes include:

- NPS 1/8 to NPS 26

- Outside Diameter: 0.405 inches to 30 inches

- Wall Thickness: Schedule 10 to Schedule 160

2.Welded A53 Grade B Pipes:

Welded pipes are formed by rolling flat steel and welding the seam, offering cost-effective solutions for many applications. Common size ranges for welded a53 gr.b pipes include:

- NPS 1/2 to NPS 24

- Outside Diameter: 0.840 inches to 24 inches

- Wall Thickness: Schedule 10 to Schedule 80

It's important to note that not all size and schedule combinations are available for both seamless and welded pipes. The availability of specific sizes and wall thicknesses may vary depending on the manufacturer and production capabilities.

3.When selecting a53 gr.b pipes for a project, consider factors such as:

- Operating pressure and temperature

- Fluid or gas being transported

- Environmental conditions

- Installation method

- Cost considerations

By understanding the standard dimensions, tolerances, and common size ranges of A53 Grade B pipes, engineers and project managers can make informed decisions to ensure the success and longevity of their piping systems.

Contact Longma

A53 Grade B pipes play a crucial role in various industries, offering reliable and versatile solutions for fluid and gas transmission. Understanding the dimensions, tolerances, and size ranges of these pipes is essential for proper selection and installation. Whether opting for seamless or welded a53 gr.b pipes, it's important to consider the specific requirements of your project and consult with experienced manufacturers to ensure the best fit for your needs.

For high-quality A53 Grade B pipes and expert guidance on pipe selection, look no further than Longma Group. As one of China's leading ERW/LSAW steel pipe manufacturers since 2003, Longma Group specializes in the production of large-diameter, thick-walled, double-sided, sub-arc-seam welding steel pipes, including LSAW (Longitudinal Submerged Arc Welded) and ERW steel pipes. With an annual output exceeding 1,000,000 tons by the end of 2023, Longma Group has the expertise and capacity to meet your piping needs. For more information or to discuss your project requirements, please contact us at info@longma-group.com.