Quality Standards and Specifications:

API 5L is a set of standards established by the American Petroleum Institute (API) that governs the manufacturing, testing, and inspection of steel pipes used for the transportation of oil, gas, and other fluids. The API 5L standard is divided into two categories: PSL1 and PSL2, with PSL1 being the more basic and PSL2 offering additional requirements for higher pressure and temperature applications.

The quality of API 5L PSL1 pipes is directly influenced by adherence to these standards. The specifications outline the chemical composition, mechanical properties, dimensions, and testing procedures that must be met to ensure the pipes are fit for their intended purpose. Compliance with API 5L standards is critical to guarantee the safety, reliability, and longevity of pipelines.

|

|

|

Manufacturing Process Quality Control:

The assembling system of Programming interface 5L PSL1 pipes includes a few phases, every one of which requires severe quality control measures. From the choice of unrefined substances to the last examination, each step is critical to guarantee the lines satisfy the necessary guidelines.

Unrefined substance determination includes picking excellent steel that meets the synthetic organization necessities illustrated in Programming interface 5L. The assembling system incorporates framing, welding, heat treatment, and non-horrendous testing (NDT) to guarantee the lines are liberated from deserts and have the important mechanical properties.

Quality control gauges likewise incorporate ordinary reviews and investigations at different phases of creation to speedily distinguish and correct any issues. This proactive way to deal with quality control keeps up with the exclusive requirements of Programming interface 5L PSL1 pipes.

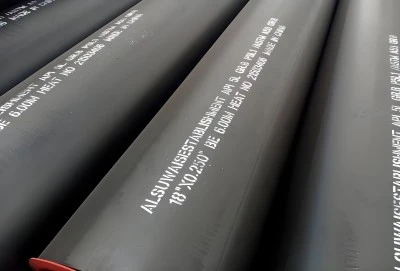

Surface Finish and Protection:

The surface completion of Programming interface 5L PSL1 pipes assumes a crucial part in their general quality. A smooth and clean surface is less inclined to hold onto impurities or start consumption, which can think twice about line's trustworthiness.

Defensive coatings are applied to the outside of the lines to give extra assurance against erosion and ecological elements. These coatings can incorporate paint, epoxy, or other specific materials intended to broaden the assistance life of the lines and decrease upkeep necessities.

Ordinary reviews and evaluations of the surface completion and defensive coatings are essential for the continuous quality control cycle to guarantee the lines stay in ideal condition.

Quality Assurance and Quality Control (QA/QC) Programs:

Effective Quality Assurance (QA) and Quality Control (QC) programs are essential for maintaining the quality of API 5L PSL1 pipes. These programs involve systematic planning, implementation, and documentation of all processes and procedures related to pipe manufacturing.

QA focuses on the overall processes and systems in place to ensure quality, while QC involves the inspection and testing of the pipes to verify they meet the required standards. Regular audits, training, and continuous improvement initiatives are part of a robust QA/QC program.

Third-Party Inspection and Certification:

Third-party inspection and certification add an extra layer of assurance to the quality of our products. Independent organizations conduct inspections and issue certifications based on their findings, providing an unbiased evaluation of the pipes' quality.

Certifications such as the API 5L certificate, ISO certificate, and QMS certificate are valuable as they demonstrate that the manufacturer meets international standards and best practices. These certifications are often required by regulatory bodies and are sought after by customers who value quality and reliability.

Wholesale API 5L PSL1 Pipe:

LONGMA GROUP is a leading supplier of high-quality API 5L PSL1 pipes, renowned for its stringent quality control measures and comprehensive certification. The company’s manufacturing process adheres to the highest standards, ensuring that each pipe meets the necessary specifications for safe and efficient operation.

Natural substance Choice:

LONGMA Gathering starts with a careful determination process for unrefined components, obtaining simply the most elevated grade steel with an exact substance sythesis. This step is key, as the nature of the steel straightforwardly influences the eventual outcome's exhibition and life span. The organization utilizes a group of specialists who investigate each clump of steel for immaculateness and consistency, guaranteeing it meets the thorough details expected for Programming interface 5L line pipes.

Framing and Welding:

Using cutting edge innovation and high level procedures, LONGMA Gathering shapes the steel into pipes with excellent accuracy. The shaping system is painstakingly controlled to accomplish the ideal measurement and wall thickness, while the welding system is executed with high-accuracy hardware to guarantee a consistent and solid bond. The organization's gifted specialists are prepared to screen these cycles intently, interceding when important to keep up with the best expectations.

Heat Treatment:

Subsequent to framing and welding, the lines go through a progression of controlled heat treatment processes. These medicines are intended to change the mechanical properties of the steel, improving its solidarity, malleability, and protection from different ecological elements. LONGMA Gathering's intensity therapy conventions are fastidiously adjusted to accomplish the ideal equilibrium of properties for the expected use of the lines.

Testing:

Quality is additionally guaranteed through a thorough testing system that incorporates both horrendous and non-disastrous testing techniques. Damaging tests, for example, pliable and influence tests, give quantitative information on the material's solidarity and strength. Non-disastrous testing, including ultrasonic, radiographic, and attractive molecule reviews, guarantees that the lines are liberated from inner and surface deformities that could think twice about honesty.

Certifications:

LONGMA Gathering's devotion to quality is perceived through a progression of renowned certificates that act as a demonstration of the organization's obligation to greatness.

Programming interface 5L Confirmation:

This accreditation affirms that LONGMA Gathering's line pipes follow the API 5L PSL1 pipes which are perceived all around the world for their rigid prerequisites on pipe fabricating.

ISO Certificate:

LONGMA Gathering additionally holds ISO confirmations, displaying the organization's devotion to global quality administration principles. These confirmations guarantee clients that LONGMA Gathering's items are fabricated under a system that stresses consistent improvement and consumer loyalty.

QMS Affirmation:

Quality Administration Framework (QMS) affirmations confirm that LONGMA Gathering has a viable framework set up for overseeing and working on the nature of its items. This framework includes all parts of the assembling system, from unrefined substance obtainment to eventual outcome conveyance.

Contact Information:

If you are looking for reliable API 5L PSL1 pipe manufacturers, LONGMA GROUP is ready to meet your needs. For more information or to place an order, please contact them at: info@longma-group.com.