API 5L welded pipes are essential components in the oil and gas industry, manufactured through various welding processes to meet specific requirements for pipeline applications. These pipes are produced according to the American Petroleum Institute's API 5L specification, which sets stringent standards for line pipe used in transportation systems. The welding methods employed significantly influence the pipe's mechanical properties, quality, and suitability for different operating conditions. The main welding types include ERW (Electrical Resistance Welding), HFW (High Frequency Welding), LSAW (Longitudinal Submerged Arc Welding), and DSAW (Double Submerged Arc Welding). Each welding method has distinct characteristics, advantages, and applications in pipeline construction. Understanding these welding types helps engineers and procurement professionals select the most appropriate pipe for their specific project requirements.

|

|

|

ERW (Electrical Resistance Weld)

Electrical Resistance Welding represents one of the most widely used methods for manufacturing API 5L welded pipes. This process involves the application of electrical current and mechanical pressure to join the edges of rolled steel strip or skelp. The welding occurs when the material reaches its fusion temperature due to electrical resistance heating. The process begins with continuous feeding of steel strip through forming rolls that gradually shape it into a tubular form. As the edges come together, copper contact wheels apply electrical current while squeeze rolls provide necessary pressure, creating a forge weld without adding filler material. Modern ERW processes typically operate at frequencies between 360-500 kHz, ensuring precise heat control and consistent weld quality. The technology enables production of pipes with diameters ranging from 8.625 inches to 24 inches, with wall thicknesses up to 0.5 inches. ERW pipes demonstrate excellent uniformity in mechanical properties and dimensional accuracy. The process offers advantages including high production speeds, cost-effectiveness, and minimal heat-affected zones. Quality control measures include ultrasonic testing of the weld seam and hydrostatic testing of finished pipes.

HFW (High Frequency Weld)

High Frequency Welding represents an advanced evolution of the ERW process, utilizing frequencies above 200 kHz for enhanced welding performance. The HFW method employs electromagnetic induction or contact heating to generate the required welding temperature. The process creates a concentrated heat pattern along the strip edges, resulting in a narrower heat-affected zone compared to conventional ERW. This technological advancement allows for improved weld quality and higher production speeds. HFW pipes exhibit superior mechanical properties, particularly in terms of impact toughness and fatigue resistance. The process accommodates pipe diameters ranging from 4 inches to 24 inches, with wall thicknesses up to 0.750 inches. Modern HFW mills incorporate sophisticated control systems that monitor and adjust welding parameters in real-time, ensuring consistent weld quality. The process features automated inspection systems, including ultrasonic testing and eddy current examination, to verify weld integrity. HFW technology demonstrates particular advantages in producing pipes for high-pressure applications and corrosive environments.

LSAW (Longitudinally Submerged Arc Welding)

Longitudinal Submerged Arc Welding represents a sophisticated welding method for producing large-diameter API 5L pipes. This process involves welding along the length of the pipe, typically utilizing a multi-wire welding system. The LSAW method begins with forming steel plate into a cylindrical shape using a U-ing and O-ing process. The longitudinal seam is then welded from both inside and outside simultaneously or sequentially. The welding occurs under a blanket of granular flux material that shields the molten metal from atmospheric contamination and produces a smooth, high-quality weld. LSAW technology enables production of pipes with diameters ranging from 16 inches to 60 inches, with wall thicknesses up to 2 inches. The process allows for precise control of heat input and penetration, resulting in superior mechanical properties at the weld joint. LSAW pipes undergo extensive non-destructive testing, including radiographic examination and ultrasonic inspection. The method proves particularly suitable for high-pressure applications and offshore pipelines where stringent quality requirements apply.

DSAW (Double Submerged Arc Welding)

Double Submerged Arc Welding represents an advanced pipe manufacturing process that employs welding from both the inside and outside of the pipe. The method utilizes multiple welding heads operating simultaneously or in sequence to create a robust weld joint. DSAW technology combines the principles of submerged arc welding with sophisticated automation to ensure consistent weld quality. The process begins with formed pipe shells that undergo precise edge preparation to achieve optimal joint geometry. Multiple welding wires deposit filler material under a protective flux cover, creating a fully penetrated weld seam. DSAW enables production of pipes with diameters ranging from 24 inches to 100 inches, accommodating wall thicknesses up to 2.5 inches. The technology incorporates advanced monitoring systems that control critical parameters including heat input, wire feed rate, and travel speed. Quality assurance involves comprehensive testing protocols including ultrasonic examination, radiographic testing, and mechanical property verification.

China API 5L Welded Pipe Supplier

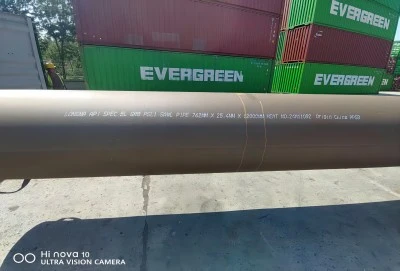

LONGMA GROUP has distinguished itself as a leading manufacturer and supplier of API 5L welded pipes in China, setting a benchmark for quality and reliability in the industry. The company upholds rigorous quality control systems that are in harmony with global benchmarks, a fact underscored by its extensive collection of certifications. This commitment to excellence is a cornerstone of LONGMA GROUP's operations, ensuring that every product meets the highest standards of performance and safety.

LONGMA GROUP's manufacturing prowess is reflected in its mastery of various welding technologies, including Electric Resistance Welding (ERW), High-Frequency Welding (HFW), and Longitudinal Submerged Arc Welding (LSAW) processes. These advanced techniques allow the company to produce a wide range of welded pipes that cater to diverse industrial needs. The company's dedication to quality is further exemplified by its API 5L Certificate, which attests to its compliance with the stringent standards set by the American Petroleum Institute for line pipe production. This certification is a mark of the company's unwavering commitment to producing pipes that are safe, reliable, and fit for purpose in the oil and gas industry.

LONGMA GROUP's ISO Certificate is a testament to its steadfast adherence to international quality management practices. This certification signifies that the company's operations are guided by a robust quality management system that ensures consistency and excellence in every aspect of production. The QMS (Quality Management System) Certificate further reinforces LONGMA GROUP's dedication to systematic quality control, ensuring that every stage of the manufacturing process is subject to meticulous oversight and scrutiny.

The production facilities at LONGMA GROUP are equipped with cutting-edge testing equipment and adhere to stringent inspection protocols. These measures are designed to verify the conformity of each product with the specified requirements, ensuring that every pipe that bears the LONGMA GROUP name is a symbol of precision and reliability. The company's investment in advanced testing and inspection equipment is a clear indication of its commitment to quality and its desire to exceed customer expectations.

LONGMA GROUP is eager to engage with potential clients and partners interested in its API 5L welded pipe products. The company invites inquiries through its official communication channel at info@longma-group.com, offering a direct line to its team of experts. This approachability is a reflection of LONGMA GROUP's customer-centric philosophy, where every inquiry is treated with the utmost importance, and every customer is valued as a potential partner in a journey towards excellence.