In the world of oil and gas transportation, the choice of pipeline material is crucial for ensuring safety, efficiency, and longevity. Among the various options available, API line pipe has emerged as a frontrunner, often outperforming other steel tubular goods. This article delves into the reasons behind the supremacy of line pipe and why it continues to be the preferred choice for engineers and industry professionals.

|

|

|

Quality of API Line Pipe

In the realm of oil and gas transportation infrastructure, API line pipe emerges as a paragon of excellence, meticulously crafted in accordance with the exacting standards established by the American Petroleum Institute (API). Its prominence is undeniably attributed to its superior quality and unwavering reliability, which are indispensable in the face of the formidable challenges posed by the oil and gas industry.

The oil and gas transportation sector is rife with extreme conditions that can test the mettle of any pipeline system. API line pipe, however, is specifically engineered to thrive in such an environment. It is designed to withstand the crushing force of high pressures, the intense fluctuations of extreme temperatures, and the insidious effects of corrosive elements that are all too common in oil and gas pipelines. This resilience is not merely a desirable trait but a critical necessity, as pipeline failures in this industry can lead to catastrophic consequences, including environmental disasters, massive financial losses, and even loss of life.

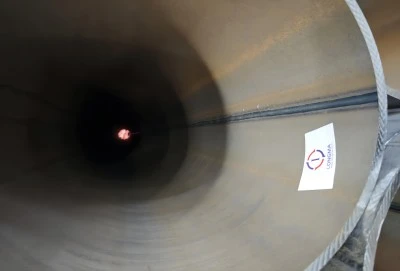

The manufacturing process is a testament to the industry's commitment to quality. It is a rigorous and methodical procedure that incorporates stringent quality control measures at every stage. From the initial selection of raw materials to the final inspection of the finished product, each pipe is subjected to a battery of tests and evaluations. This ensures that not only does each pipe meet the required specifications, but it often exceeds them, setting a new benchmark for quality in the industry.

The oil and gas industry places a premium on quality assurance, and for good reason. The potential risks associated with pipeline failures are simply too great to ignore. The superior strength of API line pipe provides it with the ability to handle the immense pressures encountered during transportation without buckling or failing. Its durability ensures that it can withstand the test of time and the harsh elements it is exposed to, reducing the need for frequent repairs and replacement. Moreover, its remarkable resistance to corrosion is a crucial factor in its longevity and reliability, as corrosion is one of the primary culprits behind pipeline failures.

API line pipe is not a one-size-fits-all solution. It is available in a wide range of grades and specifications, offering engineers the flexibility to choose the most suitable type for their specific project requirements. This versatility sets it apart from other steel tubular goods, which may have more limited applications and fail to provide the same level of customization. Whether it is a high-pressure natural gas pipeline traversing rugged terrain or an offshore oil pipeline subjected to the corrosive effects of saltwater, there is a line pipe grade that can rise to the challenge.

Cost-Effectiveness and Long-Term Value

The superior quality and durability of API line pipe serve as the cornerstone of its economic advantages. Engineered to withstand the harshest operating conditions, these pipes exhibit remarkable resistance to deformation, corrosion, and wear. As a result, they require significantly less frequent maintenance interventions compared to lower-quality alternatives. Each maintenance operation on a pipeline, especially in remote or offshore locations, involves substantial costs related to manpower, specialized equipment, and logistics. By minimizing these maintenance events, line pipe helps operators avoid the escalating expenses associated with frequent repairs and inspections.

Moreover, the extended service life of API line pipe translates into fewer replacement cycles. In the oil and gas industry, where pipelines are often designed for decades of service, the need to replace pipes prematurely can lead to massive financial burdens. The ability of line pipe to maintain its integrity and performance over an extended period ensures that operators can maximize their return on investment without the disruption and cost of early replacement projects.

In the context of large-scale oil and gas transportation projects, the cost-effectiveness of API line pipe becomes even more pronounced. These projects typically involve extensive pipeline networks covering vast geographical areas, often in challenging terrains or harsh environments. In such settings, any downtime or repair work can result in significant financial losses due to halted product flow, revenue generation disruption, and potential environmental remediation costs.

The reliability of API line pipe reduces the likelihood of unexpected failures and leakage, thereby minimizing downtime and associated financial penalties. Additionally, its proven performance allows operators to plan and budget with greater certainty, avoiding the unforeseen expenses that can arise from using less reliable materials. This financial predictability is invaluable for long-term project planning and investor confidence in large-scale energy infrastructure ventures.

Environmental and Safety Considerations

In an era of increasing environmental awareness and stringent safety regulations, API line pipe stands out for its ability to meet and exceed these demands. The high-quality standards of API line pipe contribute significantly to the prevention of leaks and spills, which can have devastating environmental impacts.

The corrosion resistance of API line pipe is particularly noteworthy in this context. Many grades of line pipe are designed to withstand corrosive environments, both internally from the transported materials and externally from soil conditions or marine environments. This resistance to corrosion not only extends the life of the pipeline but also dramatically reduces the risk of environmentally damaging leaks.

Safety is another area where API line pipe excels. The consistent quality and known performance characteristics of line pipe allow for more accurate risk assessments and more effective safety protocols. This is crucial in an industry where safety is paramount, and the consequences of failure can be severe.

Moreover, the ability of API line pipe to withstand high pressures and extreme temperatures makes it suitable for use in a wide range of environments, from deep offshore installations to Arctic conditions. This versatility ensures that safety standards can be maintained across diverse operating conditions.

High-Quality API Line Pipe

In the competitive landscape of steel tubular goods, line pipe consistently proves its superiority. Its unparalleled quality, long-term cost-effectiveness, and ability to meet stringent environmental and safety standards make it the preferred choice for engineers and industry professionals. As the oil and gas industry continues to evolve and face new challenges, the reliability and versatility of line pipe will undoubtedly ensure its continued reign as the supreme choice for pipeline projects.

For those seeking high-quality API line pipe solutions, Longma Group stands out as a leading manufacturer. With a wide range of pipe products available in various grades (B, X42, X46, X52, X56, X60, X65, X70, X80) and levels (PSL1, PSL2), Longma Group can meet diverse project requirements. Their pipes, ranging from 1/8" to 80" in outer diameter and SCH10 to SCH160 in thickness, are backed by API 5L, ISO, and QMS certifications, ensuring top-notch quality and reliability. With the fastest delivery time of just 7 days, Longma Group is committed to providing excellent products and services to meet your pipeline needs. For more information or to discuss your specific requirements, please contact Longma Group at info@longma-group.com.