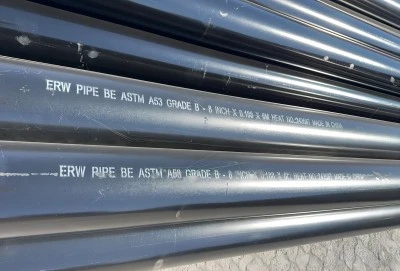

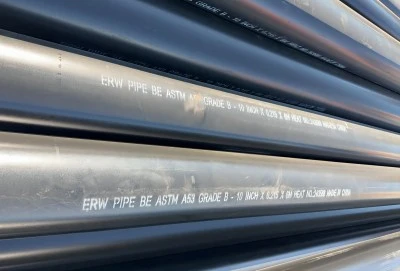

ASTM A53 Grade B black pipe is a versatile and robust steel piping solution widely used in various industrial applications. This article delves into the crucial aspects of pressure ratings, wall thickness options, and available sizes for A53 black steel pipe. Understanding these characteristics is essential for engineers, project managers, and contractors working in oil and gas transportation, water supply systems, bridge and building structures, offshore platform construction, and industrial manufacturing. We'll explore how these factors impact safety, performance, and project success in global markets, with a focus on the Middle East, Australia, and Southeast Asia.

|

|

|

Pressure Ratings: Safety First

When it comes to A53 black steel pipe, pressure ratings are paramount for ensuring safe and reliable operations. Let's dive into the key aspects of pressure ratings and their significance in various industrial applications.

ASTM A53 Grade B Pipe: Maximum Working Pressure

The maximum working pressure of ASTM A53 Grade B pipe is a critical factor in determining its suitability for specific projects. This rating depends on several variables, including pipe diameter, wall thickness, and temperature conditions. For instance, a 6-inch Schedule 40 A53 Grade B pipe typically has a maximum working pressure of around 1,130 psi at room temperature. However, it's crucial to note that this value can change significantly based on operating temperatures and environmental factors.

Engineers and project managers must carefully consider these pressure ratings when selecting A53 black steel pipe for their projects. Exceeding the maximum working pressure can lead to catastrophic failures, especially in high-stakes applications like oil and gas transportation or offshore platform construction.

Pressure Testing: Ensuring A53 Grade B Pipe Safety

Rigorous pressure testing is an integral part of quality assurance for A53 Grade B pipe. This process involves subjecting the pipe to pressures well above its intended working pressure to verify its integrity and safety margins. Typically, hydrostatic tests are conducted at pressures ranging from 1.5 to 2 times the maximum working pressure.

For example, a pipe rated for 1,000 psi might undergo testing at 1,500 to 2,000 psi. This stringent testing regimen ensures that the pipe can withstand unexpected pressure surges and provides a safety buffer for long-term use. Project procurement managers should always request and review pressure test certificates to ensure compliance with industry standards and project specifications.

Industry Standards for A53 Grade B Pressure Ratings

Several industry standards govern the pressure ratings of A53 Grade B pipe. The American Society of Mechanical Engineers (ASME) B31.3 standard for process piping and the American Petroleum Institute (API) 5L specification are two key references. These standards provide guidelines for calculating allowable stress and determining appropriate pressure ratings based on pipe dimensions and material properties.

Adhering to these standards is crucial for projects in the Middle East, Australia, and Southeast Asia, where regulatory compliance and safety are top priorities. Plant equipment managers and structural engineers must stay updated on these standards to ensure their projects meet both local and international requirements.

Wall Thickness Options: Balancing Strength and Weight

The wall thickness of A53 black steel pipe plays a crucial role in determining its strength, weight, and overall performance. Let's examine the different thickness options and their implications for various industrial applications.

A53 Grade B Pipe: Standard vs. Extra Strong Thickness

ASTM A53 Grade B pipe comes in two primary wall thickness categories: Standard (STD) and Extra Strong (XS). Standard thickness, also known as Schedule 40, is the most common option for general-purpose applications. Extra Strong, or Schedule 80, offers increased wall thickness for higher pressure ratings and improved durability.

For example, a 4-inch nominal pipe size (NPS) A53 Grade B pipe in Standard thickness has a wall thickness of 0.237 inches, while the Extra Strong version measures 0.337 inches. This increased thickness translates to higher pressure ratings and improved resistance to external forces, making it suitable for demanding environments like offshore platforms or high-pressure industrial processes.

Corrosion Allowance in A53 Grade B Wall Thickness

When selecting wall thickness for A53 black steel pipe, considering corrosion allowance is crucial, especially in corrosive environments. Engineers often add an extra thickness to account for material loss over time due to corrosion. This allowance ensures that the pipe maintains its structural integrity and pressure-bearing capability throughout its intended service life.

For instance, in a water supply system project in Southeast Asia with moderately corrosive conditions, an engineer might specify an additional 1/16 inch (1.5 mm) wall thickness as a corrosion allowance. This proactive approach helps extend the lifespan of the piping system and reduce long-term maintenance costs.

Weight Considerations for A53 Grade B Pipe Thickness

While thicker walls offer enhanced strength and durability, they also increase the overall weight of the piping system. This added weight can impact transportation costs, installation procedures, and structural support requirements. Project managers and procurement specialists must carefully balance the benefits of increased thickness against these practical considerations.

For example, a 100-foot length of 6-inch NPS A53 Grade B pipe in Standard thickness weighs approximately 1,190 pounds, while the Extra Strong version weighs about 1,620 pounds. This 36% increase in weight can significantly affect material handling, shipping costs, and installation methods, particularly in large-scale projects like oil and gas pipelines or industrial manufacturing facilities.

Size Range: From Small Diameter to Large Bore

ASTM A53 Grade B black pipe is available in a wide range of sizes to accommodate diverse project requirements. Understanding the size options and their applications is essential for making informed decisions in piping system design and procurement.

A53 Grade B Pipe Sizes: NPS 1/8 to NPS 26

The ASTM A53 standard covers a broad spectrum of pipe sizes, ranging from NPS 1/8 (0.405-inch outside diameter) to NPS 26 (26-inch outside diameter). This extensive range allows for flexibility in system design across various industries. Smaller diameters are commonly used in instrumentation and control systems, while larger sizes are prevalent in main transmission lines for oil, gas, and water transportation.

For instance, a project in the Middle East might use NPS 2 (2.375-inch OD) A53 Grade B pipe for process connections in a refinery, while simultaneously employing NPS 24 (24-inch OD) pipe for the main product transfer lines. This versatility makes A53 black steel pipe a go-to choice for comprehensive piping solutions in large-scale engineering projects.

Large Diameter A53 Grade B Pipes for Industrial Use

Large diameter A53 Grade B pipes, typically NPS 14 and above, are crucial components in industrial and infrastructure projects. These pipes are capable of handling high flow rates and pressures, making them ideal for applications such as main water supply lines, oil and gas transmission pipelines, and cooling water systems in power plants.

For example, a major water supply project in Australia might utilize NPS 24 A53 Grade B pipe to transport large volumes of water over long distances efficiently. The combination of size and material properties allows for optimal flow characteristics while maintaining structural integrity under varying environmental conditions.

Choosing the Right A53 Grade B Pipe Size for Projects

Selecting the appropriate pipe size involves considering factors such as required flow rates, pressure drop, fluid velocity, and system efficiency. Engineers must perform hydraulic calculations to determine the optimal pipe diameter that balances performance with economic considerations.

For instance, in an offshore platform project in Southeast Asia, engineers might choose NPS 8 A53 Grade B pipe for firewater systems based on required flow rates and pressure loss calculations. Simultaneously, they might opt for NPS 20 pipe for the main oil export lines to accommodate the high production volumes while minimizing pumping costs.

ASTM A53 Grade B black pipe offers a robust and versatile solution for various industrial applications, thanks to its wide range of pressure ratings, thickness options, and sizes. By understanding these key characteristics, engineers, project managers, and contractors can make informed decisions to ensure safety, efficiency, and longevity in their piping systems. Whether it's a high-pressure oil pipeline in the Middle East, a water supply network in Australia, or an offshore platform in Southeast Asia, A53 black steel pipe continues to be a reliable choice for critical infrastructure projects worldwide.

Longma Group ASTM A53 Grade B Black Pipe

When it comes to sourcing high-quality A53 black steel pipe for your projects, Hebei Longma Group stands out as a reliable and efficient supplier. With advanced production equipment imported from Germany and independently developed technologies, Longma Group ensures top-notch product quality. Their professional team of over 300 employees, including 60+ technical experts, guarantees expert support throughout your procurement process. Comprehensive testing facilities, including ultrasonic flaw detectors and X-ray systems, ensure every pipe meets stringent quality standards. With fast delivery times as short as 7 days for standard thickness pipes and a complete range of certifications including API 5L and ISO 9001, Longma Group offers both quality and efficiency. Their competitive pricing, backed by stable raw material partnerships and an integrated production model, makes them an ideal choice for your A53 steel pipe needs. For more information or to place an order, contact us at info@longma-group.com.