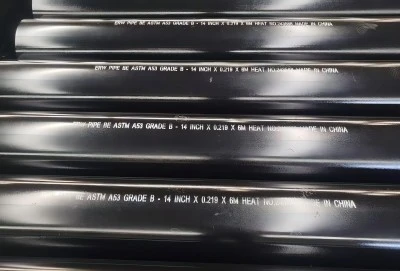

When it comes to choosing the right ASTM A53 ERW pipe for your project, understanding the differences between Grade B and Grade A is crucial. A53 ERW pipes are widely used in various industries, including oil and gas transportation, water supply systems, and structural applications. Grade B pipes generally offer superior strength and performance compared to Grade A, making them the preferred choice for many demanding applications. However, the specific requirements of your project will ultimately determine which grade is most suitable.

|

|

|

Key Differences in Chemical Composition

Carbon Content: Grade B's Higher Carbon for Strength

One of the primary distinctions between ASTM A53 Grade B pipe and Grade A ERW pipes lies in their carbon content. Grade B pipes contain a higher percentage of carbon, typically ranging from 0.30% to 0.35%, while Grade A pipes have a lower carbon content of around 0.25%. This increased carbon content in Grade B pipes contributes to their enhanced strength and durability, making them more suitable for high-pressure applications and structural uses.

The higher carbon content in Grade B pipes results in improved tensile strength and yield strength, which are critical factors in determining a pipe's ability to withstand external forces and internal pressure. This makes Grade B pipes an excellent choice for projects that require robust and reliable piping systems, such as those found in the oil and gas industry or in heavy-duty construction.

Manganese Levels: Impact on Weldability and Toughness

Another significant difference between Grade B and Grade A ERW pipes is their manganese content. Grade B pipes typically contain higher levels of manganese, ranging from 0.95% to 1.20%, compared to Grade A pipes, which have manganese levels between 0.90% and 1.20%. The increased manganese content in Grade B pipes enhances their overall strength and toughness, making them more resistant to wear and tear.

However, it's important to note that higher manganese levels can affect the weldability of the pipes. While both grades are generally considered weldable, Grade B pipes may require more careful welding procedures and skilled welders to ensure proper joint integrity. This factor should be taken into account when selecting between the two grades, especially for projects that involve extensive welding or complex joint configurations.

Phosphorus and Sulfur: Controlling Impurities

Both Grade B and Grade A ERW pipes have strict limitations on phosphorus and sulfur content to control impurities and maintain the overall quality of the steel. The maximum allowable phosphorus content for both grades is 0.05%, while the maximum sulfur content is 0.045%. These tight restrictions help ensure the pipes' integrity, corrosion resistance, and overall performance across various applications.

By carefully controlling these impurities, manufacturers can produce high-quality ERW pipes that meet the stringent requirements of international standards and industry specifications. This attention to detail in chemical composition contributes to the reliability and longevity of ASTM A53 ERW pipes, regardless of the grade chosen.

Mechanical Properties: Grade B vs A

Yield Strength: Grade B's Superior PerformanceWhen comparing the mechanical properties of ASTM A53 Grade B ERW pipe and Grade A ERW pipes, one of the most significant differences lies in their yield strength. Grade B pipes boast a minimum yield strength of 35,000 psi (240 MPa), while Grade A pipes have a lower minimum yield strength of 30,000 psi (205 MPa). This higher yield strength gives Grade B pipes a notable advantage in applications where resistance to deformation under stress is crucial.

The superior yield strength of Grade B pipes makes them particularly well-suited for use in high-pressure systems, such as those found in oil and gas transportation or industrial manufacturing. In these environments, the pipes must withstand significant internal pressures without yielding or deforming, ensuring the safety and integrity of the entire system.

Tensile Strength: Comparing A53 Grade B and A

Tensile strength is another critical mechanical property that distinguishes Grade B from Grade A ERW pipes. Grade B pipes have a minimum tensile strength of 60,000 psi (415 MPa), compared to Grade A pipes, which have a minimum tensile strength of 48,000 psi (330 MPa). This higher tensile strength enables Grade B pipes to withstand greater loads and stresses before failure, making them ideal for applications that demand exceptional durability and reliability.

The increased tensile strength of Grade B pipes is particularly beneficial in structural applications, such as bridge construction or offshore platform support systems. In these scenarios, the pipes must be able to bear substantial loads while maintaining their structural integrity over extended periods, often in challenging environmental conditions.

Elongation: Ductility Differences in ERW Pipes

Elongation is a measure of a material's ductility, or its ability to deform plastically without fracturing. Both Grade B and Grade A ERW pipes have specific elongation requirements, which are typically expressed as a percentage of the original length. Grade B pipes generally have a minimum elongation requirement of 21% in 2 inches (50.8 mm), while Grade A pipes have a slightly lower requirement of 20%.

Although the difference in elongation between the two grades is relatively small, it can be significant in certain applications. The slightly higher elongation of Grade B pipes provides them with improved formability and resistance to brittle fracture, which can be advantageous in situations where the pipes may be subject to bending or other forms of deformation during installation or use.

Choosing Between A53 Grade B and A

Application-Specific Selection: Oil & Gas vs. ConstructionWhen deciding between ASTM A53 Grade B ERW pipes and Grade A ERW pipes, it's essential to consider the specific requirements of your application. In the oil and gas industry, Grade B pipes are often preferred due to their higher strength and ability to withstand high pressures. These pipes are commonly used in gathering lines, flow lines, and distribution systems where reliability and safety are paramount.

For construction projects, the choice between Grade B and Grade A may depend on the structural demands of the building or infrastructure. Grade B pipes are often selected for load-bearing applications or in structures that require higher strength-to-weight ratios. However, Grade A pipes may be sufficient and more cost-effective for less demanding applications, such as general plumbing or low-pressure water distribution systems.

Cost-Effectiveness: Balancing Price and Performance

While Grade B pipes generally offer superior mechanical properties, they also tend to come with a higher price tag compared to Grade A pipes. When evaluating the cost-effectiveness of each grade, it's crucial to consider the long-term performance requirements of your project. In some cases, the initial higher cost of Grade B pipes may be offset by their longer service life and reduced maintenance needs.

For projects with tight budgets or less demanding performance requirements, Grade A pipes may provide a more economical solution without compromising safety or functionality. It's important to work closely with engineers and suppliers to determine the most cost-effective option that meets your project's specific needs and regulatory requirements.

Industry Standards: Meeting Project Requirements

Both Grade B and Grade A ERW pipes must meet the standards set forth in ASTM A53/A53M. However, some industries or regions may have additional requirements or preferences for one grade over the other. For example, certain building codes or oil and gas industry standards may specify the use of Grade B pipes for specific applications.

It's crucial to consult relevant industry standards, local regulations, and project specifications when selecting between Grade B and Grade A pipes. This ensures compliance with all applicable requirements and helps prevent potential issues during inspections or certification processes.

Choosing between ASTM A53 Grade B and Grade A ERW pipes requires careful consideration of various factors, including chemical composition, mechanical properties, and specific application requirements. While Grade B pipes generally offer superior strength and performance, Grade A pipes may be suitable for less demanding applications and can provide a more cost-effective solution in certain scenarios. By understanding the key differences between these two grades and evaluating your project's unique needs, you can make an informed decision that ensures optimal performance, safety, and longevity for your piping system.

ASTM A53 ERW Pipes For Sale

For high-quality ASTM A53 ERW pipes that meet your project's specific requirements, look no further than Hebei Longma Group. Our state-of-the-art production facilities, which include equipment imported from Germany and four independently developed production lines, ensure consistent quality and precision in every pipe we manufacture. With a professional team of over 300 employees, including more than 60 technical experts, we have the expertise to meet even the most demanding specifications.

Our comprehensive testing facilities, including online ultrasonic automatic flaw detectors and industrial X-ray television, guarantee that every pipe meets the highest standards of quality and reliability. We pride ourselves on fast delivery, with the ability to complete production of standard thickness steel pipes in as little as 7 days. Hebei Longma Group holds all necessary certifications, including API 5L, ISO 9001, ISO 14001, and FPC, ensuring that our products meet global industry standards.

Thanks to our long-term relationships with raw material suppliers and our integrated production model, we offer competitive pricing without compromising on quality. To learn more about our A53 ERW pipes or to request a quote, contact us at info@longma-group.com.