Yes, you can weld black steel pipe. It is a popular choice for many industrial and construction applications due to its strength, durability, and weldability. This type of pipe is commonly used in oil and gas transportation, water supply systems, and structural projects. Welding black pipe requires proper techniques and precautions to ensure strong, reliable joints that can withstand high pressures and harsh environments.

|

|

|

Black Steel Pipe Welding: Techniques and Tips

Preparing black steel pipe for welding

Before welding black steel pipe, proper preparation is crucial to ensure a strong and durable joint. Start by cleaning the pipe surfaces thoroughly, removing any dirt, oil, or rust using a wire brush or grinder. This step is essential for creating a clean surface that allows for optimal weld penetration and adhesion.

Next, bevel the pipe edges to create a V-shaped groove. This groove helps ensure full penetration of the weld and reduces the risk of incomplete fusion. The bevel angle typically ranges from 30 to 37.5 degrees, depending on the pipe thickness and welding method chosen.

Proper alignment of the pipes is critical for a successful weld. Use pipe clamps or a welding jig to hold the pipes in place and maintain the correct alignment throughout the welding process. This step helps prevent misalignment issues that could compromise the integrity of the welded joint.

Choosing the right welding method for black steel

Several welding methods are suitable for black steel pipe, each with its advantages and applications. The most common methods include:

1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, this method is versatile and widely used for black steel pipe welding. It's particularly suitable for outdoor applications and can be used in various positions.

2. Gas Tungsten Arc Welding (GTAW): Also called TIG welding, this method produces high-quality welds with excellent control. It's often used for root passes and thin-walled pipes.

3. Gas Metal Arc Welding (GMAW): Commonly referred to as MIG welding, this method offers high deposition rates and is suitable for thicker pipes. It's often used in shop environments due to its sensitivity to wind.

4. Flux-Cored Arc Welding (FCAW): This method combines the advantages of SMAW and GMAW, offering good penetration and high deposition rates. It's particularly useful for outdoor welding in windy conditions.

The choice of welding method depends on factors such as pipe thickness, project requirements, and environmental conditions. For critical applications in the oil and gas industry or water supply systems, it's essential to consult relevant standards such as API 1104 or AWS D1.1 to ensure compliance with industry-specific requirements.

Post-weld treatments for black steel pipe joints

After welding, proper post-weld treatments are essential to ensure the longevity and performance of the welded joint. These treatments help relieve stress, improve corrosion resistance, and enhance the overall quality of the weld.

One common post-weld treatment is stress relief heat treatment. This process involves heating the welded area to a specific temperature and holding it for a predetermined time before allowing it to cool slowly. This treatment helps reduce residual stresses in the weld and surrounding material, minimizing the risk of cracking or distortion.

Another important post-weld treatment is cleaning and inspecting the weld. Remove any slag or spatter using a chipping hammer and wire brush. Conduct a visual inspection to check for any defects such as cracks, porosity, or undercut. For critical applications, non-destructive testing methods like ultrasonic testing or radiographic inspection may be necessary to ensure the integrity of the weld.

Finally, consider applying a protective coating to the welded area to enhance corrosion resistance. This is particularly important for black steel pipes used in corrosive environments or exposed to moisture. Options include paint, epoxy coatings, or galvanization, depending on the specific application and environmental conditions.

Challenges in Welding Black Steel Pipe

Dealing with carbon content in black steel weldingOne of the primary challenges in welding black steel pipe is managing its carbon content. Black steel typically contains a higher carbon content compared to other steel grades, which can affect its weldability and the properties of the welded joint.

The higher carbon content in black steel can lead to increased hardness in the heat-affected zone (HAZ) of the weld. This hardness can make the welded area more susceptible to cracking, particularly in thicker pipes or when rapid cooling occurs. To mitigate this risk, consider the following strategies:

1. Preheat the pipe: Preheating the pipe before welding can help slow down the cooling rate, reducing the risk of hardness-induced cracking. The preheating temperature typically ranges from 150°C to 300°C, depending on the pipe thickness and carbon content.

2. Use low-hydrogen electrodes: When using SMAW, opt for low-hydrogen electrodes to minimize the risk of hydrogen-induced cracking in the hardened HAZ.

3. Implement proper interpass temperature control: Maintain the correct interpass temperature between weld passes to ensure consistent cooling rates and minimize the risk of hardness variations.

4. Consider post-weld heat treatment: For thick-walled pipes or high-carbon steel, post-weld heat treatment can help reduce hardness and residual stresses in the welded joint.

Preventing distortion during black steel pipe welding

Distortion is another significant challenge when welding black steel pipe, particularly for large-diameter or thin-walled pipes. Welding-induced heat can cause the pipe to expand and contract unevenly, leading to warping or misalignment. To minimize distortion:

1. Use proper fixturing: Employ robust pipe clamps or welding jigs to hold the pipes securely in place during welding.

2. Implement a balanced welding sequence: Alternate welding sides and use a step-back or skip welding technique to distribute heat more evenly.

3. Control heat input: Use appropriate welding parameters and techniques to minimize excessive heat input, such as pulsed welding or the stringer bead technique.

4. Apply back-stepping: Weld in short segments, moving backward to help balance the heat distribution and reduce overall distortion.

Overcoming corrosion issues in welded black steel pipes

Corrosion is a significant concern for welded black steel pipes, especially in harsh environments or when transporting corrosive materials. The welded area can be particularly vulnerable to corrosion due to changes in the material's microstructure and the presence of residual stresses. To enhance corrosion resistance:

1. Proper surface preparation: Ensure thorough cleaning of the pipe surfaces before welding to remove any contaminants that could promote corrosion.

2. Use appropriate filler metals: Select filler metals that provide good corrosion resistance and are compatible with the base material.

3. Implement post-weld cleaning: Remove all slag, spatter, and oxides from the welded area to prevent localized corrosion initiation points.

4. Apply protective coatings: Use corrosion-resistant coatings or linings to protect the welded area and the entire pipe system from corrosive environments.

5. Consider cathodic protection: For buried pipelines or offshore applications, implement cathodic protection systems to prevent electrochemical corrosion.

Safety Precautions for Black Steel Pipe Welding

Essential protective gear for black steel weldingSafety is paramount when welding black steel pipe, especially in industrial settings. Proper personal protective equipment (PPE) is essential to protect welders from various hazards associated with the welding process. The following protective gear is crucial:

1. Welding helmet: Use an auto-darkening welding helmet with the appropriate shade level to protect your eyes from harmful UV and infrared radiation. Ensure the helmet provides full face coverage.

2. Flame-resistant clothing: Wear flame-resistant coveralls or jackets and pants to protect against sparks and spatter. Avoid synthetic materials that can melt and cause severe burns.

3. Welding gloves: Use heavy-duty leather gloves designed for welding to protect your hands from heat, sparks, and potential electric shock.

4. Safety boots: Wear steel-toed boots with non-slip soles to protect your feet from falling objects and provide electrical insulation.

5. Respiratory protection: In confined spaces or when welding galvanized or coated steel, use appropriate respiratory protection to prevent inhalation of harmful fumes.

Proper ventilation for black steel pipe welding areas

Adequate ventilation is crucial when welding black steel pipe to remove harmful fumes and gases produced during the welding process. Proper ventilation helps maintain air quality and protects welders from respiratory hazards. Consider the following ventilation strategies:

1. Local exhaust ventilation: Use fume extraction systems with movable hoods positioned close to the welding area to capture fumes at their source.

2. General ventilation: Ensure proper airflow in the welding area through natural ventilation or mechanical systems to dilute and remove contaminants.

3. Confined space considerations: When welding in confined spaces, such as inside large-diameter pipes or tanks, implement forced air ventilation systems and monitor air quality continuously.

4. Outdoor welding: When welding outdoors, position yourself upwind of the welding area to minimize exposure to fumes and gases.

Fire safety measures when welding black steel pipes

Welding black steel pipe poses significant fire hazards due to the high temperatures and sparks produced during the process. Implementing proper fire safety measures is essential to prevent accidents and protect personnel and property:

1. Clear the area: Remove all flammable materials from the welding area, including rags, paper, and combustible liquids.

2. Fire watch: Assign a dedicated fire watch person to monitor the welding area during and after welding operations, equipped with appropriate fire extinguishing equipment.

3. Fire blankets: Use fire-resistant blankets or shields to contain sparks and protect nearby equipment or structures.

4. Fire extinguishers: Keep appropriate fire extinguishers readily available in the welding area. Ensure all personnel are trained in their use.

5. Hot work permits: Implement a hot work permit system to ensure proper safety measures are in place before welding operations begin, especially in hazardous or confined areas.

Where to Buy Black Steel Pipes?

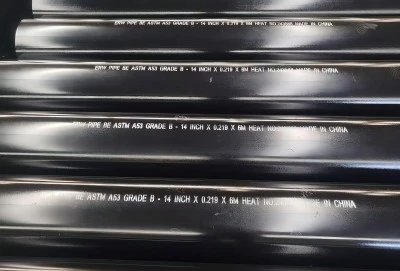

When it comes to sourcing high-quality black pipes for your welding projects, look no further than Hebei Longma Group. We offer a comprehensive range of pipes suitable for various applications in the oil and gas, water supply, and construction industries. Our state-of-the-art production facilities, equipped with advanced German machinery, ensure consistent quality and precision in every pipe we manufacture. With our team of over 300 skilled employees, including 60+ technical experts, we guarantee top-notch products that meet international standards.

Our commitment to quality is evident in our comprehensive testing facilities, which include online ultrasonic automatic flaw detectors and industrial X-ray television. We pride ourselves on fast delivery times, with standard thickness pipes ready in as little as 7 days. Our products are backed by numerous certifications, including API 5L, ISO 9001, and ISO 14001, ensuring compliance with global industry standards.

At Hebei Longma Group, we understand the importance of cost-effectiveness in large-scale projects. Our long-standing relationships with raw material suppliers, combined with our efficient production processes and rigorous quality control, allow us to offer competitive prices without compromising on quality. For all your black steel pipe needs, contact us at info@longma-group.com. Our team is ready to assist you with expert advice and tailored solutions for your specific project requirements.