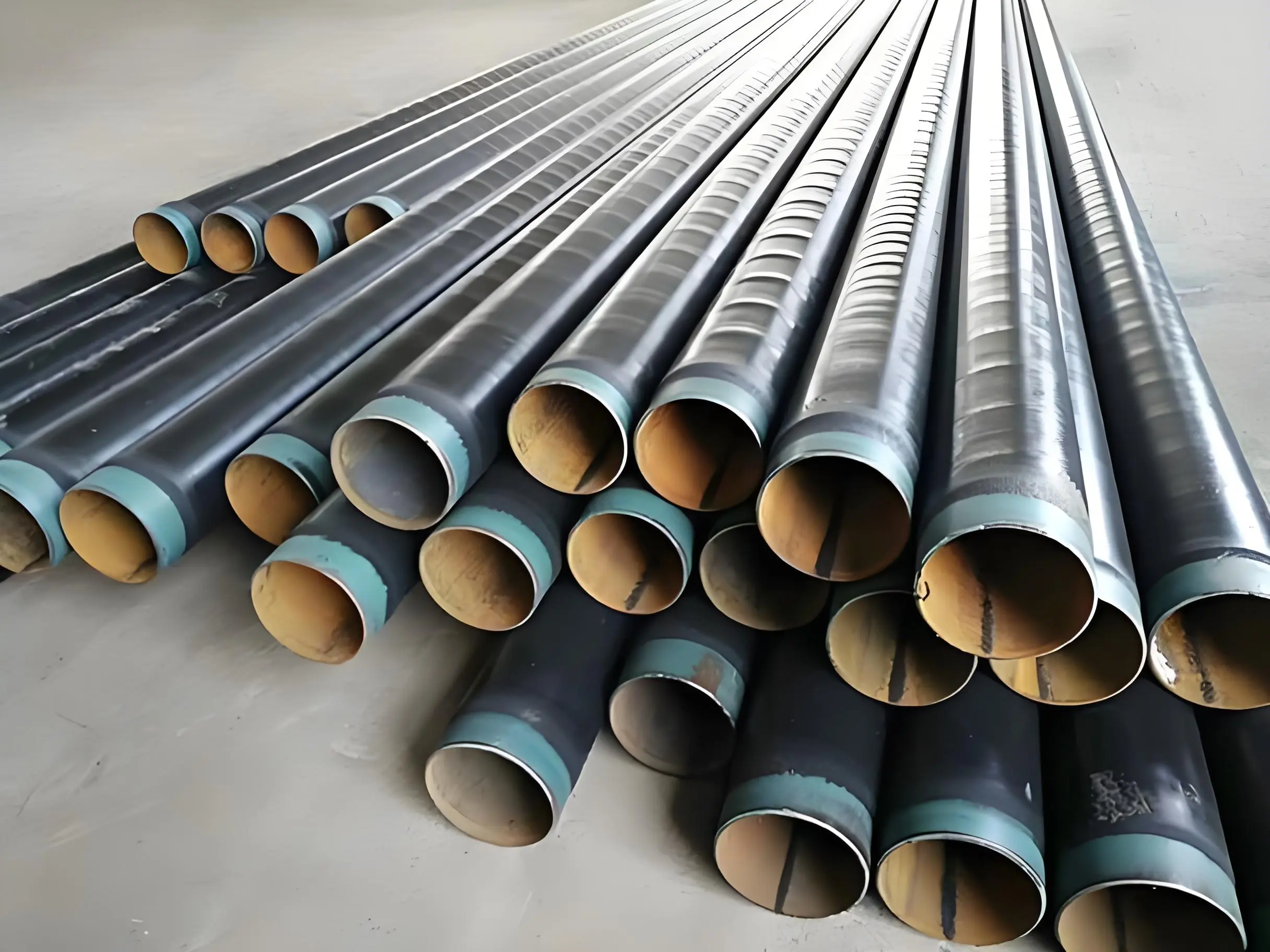

In the world of pipeline engineering, PE coated steel pipes have revolutionized the industry with their exceptional durability and corrosion resistance. When it comes to choosing between 2PE and 3PE coatings, engineers and project managers often find themselves at a crossroads. This comprehensive guide delves into the key differences, performance characteristics, and cost-effectiveness of 2PE and 3PE coated pipes, helping you make an informed decision for your next project. Whether you're working on oil and gas transportation, water supply systems, or offshore platforms, understanding these coating options is crucial for ensuring long-lasting and efficient pipeline infrastructure.

|

|

|

Key differences: 2PE and 3PE coating structures

Composition and layers of 2PE vs 3PE coatings

The fundamental difference between 2PE and 3PE coated steel pipe lies in their layer composition. 2PE coatings consist of two layers: an epoxy primer and a polyethylene topcoat. This dual-layer system provides a robust barrier against corrosion and mechanical damage. On the other hand, 3PE coatings add an extra layer to the mix, incorporating an adhesive layer between the epoxy primer and the polyethylene topcoat. This additional layer enhances the overall bonding strength and durability of the coating system.

Adhesion strength: How 2PE and 3PE bond to steel pipes

Adhesion strength is a critical factor in determining the effectiveness of pipe coatings. 2PE coatings rely on the direct bond between the epoxy primer and the steel surface, which is generally sufficient for many applications. However, 3PE coatings take adhesion to the next level. The intermediate adhesive layer in 3PE coatings acts as a bridge between the epoxy primer and the polyethylene topcoat, creating a stronger and more resilient bond. This enhanced adhesion makes 3PE coatings particularly suitable for demanding environments and high-stress applications.

Thickness variations: Impact on pipe protection

Coating thickness plays a vital role in determining the level of protection offered to steel pipes. 2PE coatings typically range from 1.8 to 3.2 mm in thickness, providing adequate protection for many standard applications. 3PE coated steel pipe, with their additional layer, generally offer a thickness range of 2.2 to 3.7 mm. This increased thickness translates to improved resistance against mechanical damage, abrasion, and environmental factors. For projects requiring maximum protection, such as deep-sea pipelines or areas with aggressive soil conditions, the extra thickness of 3PE coatings can be a game-changer.

Performance in harsh environments: 2PE vs 3PE

Corrosion resistance: 2PE and 3PE in aggressive soilsWhen it comes to corrosion resistance, both 2PE and 3PE coated steel pipes offer excellent protection. However, in highly aggressive soil conditions, 3PE coatings often have the edge. The additional adhesive layer in 3PE coatings provides an extra barrier against moisture ingress and chemical attacks. This enhanced protection is particularly valuable in areas with high salinity, extreme pH levels, or microbial activity. For pipeline projects in coastal regions or industrial zones with contaminated soils, the superior corrosion resistance of 3PE coatings can significantly extend the service life of the infrastructure.

Temperature tolerance: Hot and cold climate applications

Temperature fluctuations can put significant stress on pipe coatings, potentially leading to disbondment or cracking. 2PE coatings generally perform well in moderate temperature ranges, typically from -40°C to 60°C. 3PE coatings, however, offer a wider temperature tolerance, often ranging from -45°C to 85°C. This expanded temperature range makes 3PE coated steel pipe an ideal choice for projects in extreme climates, such as arctic regions or desert environments. The additional adhesive layer in 3PE coatings helps maintain flexibility and adhesion even under severe temperature variations, ensuring long-term protection for the steel pipes.

Mechanical protection: Abrasion and impact resistance

In areas where pipelines are subject to high mechanical stress, such as rocky terrains or underwater installations, the ability to withstand abrasion and impact is crucial. While 2PE coatings offer good mechanical protection, 3PE coated steel pipe generally provides superior resistance to abrasion and impact. The extra layer in 3PE coatings acts as a shock absorber, dissipating energy from impacts and reducing the risk of coating damage. This enhanced mechanical protection is particularly valuable in offshore applications, where pipes may be exposed to harsh underwater conditions and potential impacts from marine equipment or debris.

Cost-effectiveness: Choosing between 2PE and 3PE

Initial investment: Material and application costsWhen considering the initial investment, 2PE coatings typically have a lower upfront cost compared to 3PE coated steel pipe. The materials used in 2PE coatings are generally less expensive, and the application process is simpler, requiring fewer steps and less specialized equipment. This can make 2PE coatings an attractive option for projects with tight budgets or less demanding environmental conditions. However, it's important to note that the cost difference between 2PE and 3PE coatings has narrowed in recent years due to advancements in manufacturing processes and increased demand for high-performance coatings.

Long-term savings: Maintenance and replacement factors

While 2PE coatings may offer initial cost savings, the long-term economics often favor coated steel pipe. The superior durability and enhanced protection provided by 3PE coatings can lead to significant reductions in maintenance requirements and extend the overall lifespan of the pipeline infrastructure. This translates to fewer repairs, less frequent inspections, and reduced downtime over the life of the project. For large-scale installations or projects in challenging environments, the long-term savings associated with 3PE coatings can far outweigh the higher initial investment.

ROI analysis: 2PE vs 3PE for different project scales

Conducting a thorough return on investment (ROI) analysis is crucial when deciding between 2PE and 3PE coatings. For smaller projects or those with relatively benign environmental conditions, the lower initial cost of 2PE coatings may yield a better short-term ROI. However, for large-scale projects, critical infrastructure, or installations in harsh environments, the long-term benefits of 3PE coatings often result in a higher ROI. Factors such as project lifespan, environmental conditions, maintenance costs, and potential downtime should all be carefully considered in the ROI calculation. Ultimately, the choice between 2PE and 3PE coatings should align with the specific requirements and economic goals of each project.

The choice between 2PE and 3PE coated pipes depends on various factors, including project requirements, environmental conditions, and budget constraints. While 2PE coatings offer good protection at a lower initial cost, 3PE coatings provide superior performance in harsh environments and potentially greater long-term value. For critical infrastructure projects or installations in challenging conditions, the enhanced durability and protection of 3PE coatings often justify the higher upfront investment. Ultimately, a careful evaluation of project-specific factors and a comprehensive ROI analysis will guide you to the optimal coating solution for your pipeline project.

PE Coated Steel Pipe Supplier

Hebei Longma Group stands out as a leading supplier of high-quality PE coated steel pipes. With advanced production equipment imported from Germany and independently developed technologies, Longma Group ensures top-notch product quality. Our professional team of over 300 employees, including 60+ technical experts, guarantees excellence in every aspect of production. Comprehensive testing facilities, including ultrasonic flaw detectors and X-ray equipment, ensure stringent quality control. We offer fast delivery, with standard thickness pipes ready in as little as 7 days. Longma Group holds all necessary certifications, including API 5L, ISO 9001, and ISO 14001. Our competitive pricing is achieved through stable raw material partnerships and efficient production processes. For PE-coated steel pipes meeting API 5L, ASTM A53, EN10210, and AS/NZS 1163 standards, with coating options conforming to DIN 30670, ISO21809-1, and more, contact us at info@longma-group.com.