When it comes to protecting pipelines from corrosion, two popular choices stand out: Fusion Bonded Epoxy (FBE) and liquid epoxy coatings. Both options offer excellent protection for epoxy coated carbon steel pipes, but they differ in application methods, performance, and cost-effectiveness. This comprehensive comparison will help pipeline engineers, project managers, and contractors make informed decisions for their oil, gas, and water transportation projects across the globe, particularly in challenging environments like the Middle East, Australia, and Southeast Asia.

|

|

|

Key differences in application methods

FBE powder coating vs. liquid epoxy application techniques

FBE and liquid epoxy coatings have distinct application processes that significantly impact their performance and suitability for various projects. FBE is applied as a dry powder, electrostatically charged and sprayed onto preheated pipes. The powder melts, flows, and cures to form a uniform, solid coating. This method allows for quick application and fast curing times, making it ideal for high-volume production.

On the other hand, liquid epoxy is applied as a two-component system, mixed just before use. It's typically sprayed or brushed onto the pipe surface and requires longer curing times. While this method offers flexibility in application, it can be more labor-intensive and time-consuming, especially for large-scale projects.

Temperature requirements for FBE and liquid epoxy coatings

Temperature plays a crucial role in the application and curing of both epoxy coated carbon steel pipe types. FBE requires higher temperatures, typically between 180°C to 250°C (356°F to 482°F), for proper application. This heat requirement ensures rapid curing and excellent bonding but may limit on-site application options.

Liquid epoxy coatings can be applied at lower temperatures, often between 10°C to 50°C (50°F to 122°F), depending on the specific formulation. This wider temperature range makes liquid epoxy more versatile for field applications and repairs, especially in areas with unpredictable weather conditions.

Surface preparation: Abrasive blasting vs. chemical treatment

Proper surface preparation is critical for both coating types to ensure optimal adhesion and long-term performance. FBE typically requires abrasive blasting to achieve a clean, rough surface profile. This process removes contaminants and creates a suitable anchor pattern for the powder coating to adhere to.

Liquid epoxy coatings often allow for more flexibility in surface preparation. While abrasive blasting is still preferred, some formulations can be applied after chemical treatment or power tool cleaning. This flexibility can be advantageous in situations where abrasive blasting is not feasible or cost-effective.

Long-term performance: FBE vs. liquid epoxy

Chemical resistance comparison of FBE and liquid epoxyBoth FBE and liquid epoxy coatings offer excellent chemical resistance, crucial for protecting pipelines in various industries. FBE coatings generally provide superior resistance to a wide range of chemicals, including hydrocarbons, acids, and alkalis. This broad-spectrum protection makes FBE an excellent choice for oil and gas pipelines exposed to harsh chemicals.

Liquid epoxy coatings also offer good chemical resistance, but their performance can vary depending on the specific formulation. Some advanced liquid epoxy systems can match or even exceed FBE in certain chemical environments. However, for applications requiring the highest level of chemical resistance, FBE often remains the preferred choice.

Durability and adhesion strength in harsh environments

When it comes to durability and adhesion strength, FBE generally has the edge, especially in harsh environments. The molecular structure of FBE creates a strong, cross-linked network that provides excellent resistance to cathodic disbondment, impact, and abrasion. This durability is particularly valuable for pipelines in offshore platforms or buried underground.

Liquid epoxy coatings can also offer good durability and adhesion, but they may be more susceptible to environmental factors during application and curing. However, advancements in liquid epoxy technology have led to improved formulations that can withstand challenging conditions, making them viable alternatives in many applications.

Lifecycle analysis: FBE vs. liquid epoxy pipeline coatings

When considering the lifecycle of pipeline coatings, FBE often comes out on top. Its superior durability and resistance to degradation can lead to longer service life, reducing the need for frequent maintenance or recoating. This longevity is particularly beneficial for large-scale projects where access for maintenance can be challenging and costly.

Liquid epoxy coatings may require more frequent maintenance or reapplication, depending on the specific environmental conditions and formulation used. However, their ease of repair and touchup in the field can be advantageous for ongoing maintenance programs. When considering lifecycle costs, it's essential to factor in both initial application and long-term maintenance requirements.

Cost-effectiveness: Which coating system wins?

Initial investment: FBE vs. liquid epoxy application costsThe initial investment for FBE coating systems is typically higher than that of liquid epoxy. FBE requires specialized equipment for powder application and high-temperature curing, which can be a significant upfront cost. Additionally, the energy requirements for heating pipes during the FBE application process contribute to higher initial expenses.

Liquid epoxy coatings generally have lower initial application costs. The equipment needed for liquid epoxy application is often less expensive and more readily available. This lower barrier to entry makes liquid epoxy an attractive option for smaller projects or companies just entering the pipeline coating market.

Maintenance expenses over time for both coating systems

While FBE may have higher upfront costs, its long-term maintenance expenses are often lower. The superior durability and chemical resistance of FBE coatings typically result in fewer repairs and less frequent recoating requirements. This can lead to significant cost savings over the life of the pipeline, especially for large-scale or remote projects where maintenance access is challenging.

Liquid epoxy coatings may require more frequent maintenance and reapplication, potentially leading to higher long-term costs. However, the ease of repair and touchup for liquid epoxy coatings can be advantageous in certain situations, allowing for quick and cost-effective maintenance when needed.

ROI analysis: FBE and liquid epoxy in pipeline projects

When conducting a return on investment (ROI) analysis for pipeline coating projects, it's crucial to consider both short-term and long-term factors. FBE coatings often provide a better long-term ROI due to their extended service life and reduced maintenance requirements. This is particularly true for large-scale projects or those in harsh environments where frequent maintenance is costly and disruptive.

Liquid epoxy coatings may offer a more attractive short-term ROI due to lower initial costs. For smaller projects or those with shorter expected lifespans, liquid epoxy can be a cost-effective solution. Additionally, in regions where FBE application equipment is not readily available, liquid epoxy may provide a better overall ROI when factoring in logistics and equipment costs.

Both FBE and liquid epoxy coatings have their place in pipeline corrosion protection. Epoxy-coated carbon steel pipe excels in durability, chemical resistance, and long-term performance, making it ideal for large-scale, long-life projects in harsh environments. Liquid epoxy offers flexibility, lower initial costs, and easier field application, suitable for smaller projects or areas with limited access to specialized equipment. The choice between FBE and liquid epoxy ultimately depends on project-specific factors, including environmental conditions, budget constraints, and long-term maintenance plans. By carefully considering these factors, pipeline professionals can make informed decisions to ensure optimal corrosion protection for their projects.

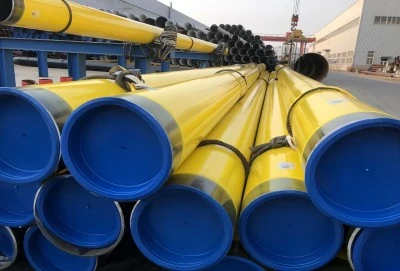

China Epoxy Coated Carbon Steel Pipe Factory

Hebei Longma Group stands out as a leading manufacturer of epoxy coated carbon steel pipes, offering cutting-edge solutions for corrosion protection in pipeline projects worldwide. With advanced production equipment imported from Germany and independently developed technologies, Longma Group ensures top-quality products that meet international standards. Our professional team of over 300 employees, including 60+ technical experts, guarantees innovation and excellence in every pipe we produce.

Our comprehensive testing facilities, including ultrasonic flaw detectors and industrial X-ray systems, ensure the highest quality control standards. We pride ourselves on fast delivery, with the ability to complete standard thickness steel pipes in just 7 days. Longma Group holds multiple certifications, including API 5L, ISO 9001, and ISO 14001, demonstrating our commitment to quality and environmental responsibility.

Thanks to our long-term partnerships with raw material suppliers and efficient production processes, we offer competitive pricing without compromising on quality. For top-quality epoxy coated carbon steel pipes that meet API 5L, ASTM A53, EN10210, and AS/NZS 1163 standards, with coating options compliant with DIN 30670, DIN30678, CSAZ245.20, EN10339, ISO21809-1, AWWAC210, and C213, contact us at info@longma-group.com. Our pipes are available in outer diameters ranging from 60.3mm to 1422mm and wall thicknesses from 6.02mm to 50.8mm, suitable for a wide range of applications in the oil, gas, and water transportation industries.