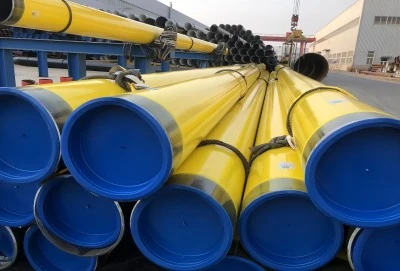

External Fusion Bonded Epoxy (FBE) coating for steel pipe has revolutionized the pipeline industry, offering unparalleled protection against corrosion and extending the lifespan of critical infrastructure. This advanced coating technology, applied to fusion bonded epoxy coated steel pipe, creates a robust barrier that shields pipes from harsh environmental factors. Whether used in oil and gas transportation, water supply systems, or offshore platforms, FBE-coated pipes have become the gold standard for durability and performance in demanding conditions.

|

|

|

FBE Coating Enhances Pipe Durability

FBE's Superior Corrosion Resistance for Steel PipesThe exceptional corrosion resistance of FBE coatings is a game-changer for steel pipe protection. This advanced coating forms an impenetrable barrier against moisture, chemicals, and other corrosive elements that typically plague unprotected steel. The unique molecular structure of FBE allows it to bond directly with the steel surface, creating a seamless shield that prevents rust and degradation.

In rigorous testing environments, fusion bonded epoxy coated steel pipes have consistently outperformed traditional coating methods. They've demonstrated remarkable resilience in both underground and underwater applications, where corrosive soil conditions and saltwater exposure pose significant threats to pipe integrity. This superior protection translates to fewer leaks, reduced maintenance, and improved overall system reliability.

Extended Pipe Lifespan with FBE Protective Layer

The longevity of fusion bonded epoxy coated steel pipes is truly impressive. While uncoated steel pipes may succumb to corrosion within a decade, FBE-protected pipes can remain in service for 50 years or more. This extended lifespan is attributed to the coating's ability to maintain its protective properties over time, even under extreme conditions.

The durability of FBE coatings also means less frequent pipe replacements, resulting in significant cost savings for infrastructure projects. Project managers and engineers appreciate the reduced downtime and lower lifecycle costs associated with these long-lasting pipes.

FBE's Chemical and Abrasion Resistance Properties

Beyond corrosion protection, FBE coatings offer excellent resistance to a wide range of chemicals and abrasive forces. This makes them ideal for use in diverse industrial applications, from transporting crude oil to handling aggressive chemicals in manufacturing processes. The coating's ability to withstand physical impacts and abrasion also protects pipes during installation and operation, ensuring their integrity in challenging environments.

The versatility of FBE coatings allows for their use in high-temperature applications, maintaining their protective properties in environments up to 230°F (110°C). This temperature resistance, combined with chemical stability, makes FBE-coated pipes a go-to solution for complex industrial projects worldwide.

FBE vs Traditional Pipe Coatings: A Comparison

FBE vs 3LPE: Choosing the Right Pipe CoatingWhen comparing FBE to Three-Layer Polyethylene (3LPE) coatings, several factors come into play. FBE offers superior adhesion to steel, providing better protection against cathodic disbondment. It also performs exceptionally well in high-temperature environments, making it suitable for a broader range of applications.

3LPE, on the other hand, offers excellent mechanical protection and is often preferred for large-diameter pipes in trenchless installation methods. The choice between FBE and 3LPE often depends on specific project requirements, environmental conditions, and installation techniques.

Cost-Effectiveness of FBE Compared to Other Coatings

While the initial cost of FBE coating may be higher than some traditional alternatives, its long-term value is undeniable. The extended service life and reduced maintenance needs of fusion bonded epoxy coated steel pipes often result in lower total ownership costs over the project lifecycle. Additionally, the coating's durability means fewer repairs and replacements, minimizing operational disruptions and associated expenses.

For project procurement managers, the cost-benefit analysis of FBE coatings often reveals substantial savings in the long run, particularly for critical infrastructure with high failure consequences.

Environmental Impact: FBE's Eco-Friendly Advantages

FBE coatings align well with growing environmental concerns in the industry. Unlike some traditional coatings, FBE is free from volatile organic compounds (VOCs) and does not release harmful substances into the environment during application or use. The coating's durability also contributes to resource conservation by reducing the need for frequent pipe replacements.

Furthermore, at the end of a pipe's service life, FBE-coated steel can be recycled more easily than pipes with other coating types, supporting sustainable practices in the construction and industrial sectors.

3 Key Benefits of FBE-Coated Steel Pipes

Improved Flow Efficiency in FBE-Coated Pipelines

FBE coatings contribute to improved flow efficiency within pipelines. The smooth surface of the coating reduces friction between the pipe wall and the transported fluid, allowing for more efficient flow rates. This enhanced efficiency can lead to energy savings in pumping operations and increased throughput capacity.

For plant equipment managers, this improved flow efficiency translates to optimized operations and potential cost savings in energy consumption. The smooth internal surface also minimizes the buildup of deposits, maintaining consistent flow characteristics over time.

FBE's Versatility in Harsh Operating Environments

FBE-coated steel pipes demonstrate remarkable versatility across a wide range of challenging environments. From the scorching heat of Middle Eastern deserts to the frigid waters of offshore platforms in Australia, these pipes maintain their integrity and performance. The coating's resistance to UV radiation, temperature fluctuations, and chemical exposure makes it an ideal choice for diverse global projects.

This versatility is particularly valuable for large-scale engineering contractors working on international projects, as it simplifies material selection and ensures consistent performance across varied geographical and operational contexts.

Reduced Maintenance Costs with FBE-Coated Pipes

The durability and corrosion resistance of FBE coatings significantly reduce the need for regular maintenance and repairs. This translates to lower operational costs and minimized downtime for pipeline systems. The coating's ability to withstand aggressive cleaning methods also simplifies maintenance procedures when they are necessary.

For facility managers and maintenance teams, the reduced maintenance requirements of fusion bonded epoxy coated steel pipes mean fewer inspections, less frequent replacements, and overall improved system reliability. This is especially crucial in remote or hard-to-access installations where maintenance operations can be challenging and costly.

External Fusion Bonded Epoxy coating for steel pipe stands out as a superior solution for protecting critical pipeline infrastructure. Its unmatched corrosion resistance, extended service life, and versatility make it an invaluable asset in various industries, from oil and gas to water distribution. As global demand for reliable and durable pipeline systems continues to grow, FBE-coated steel pipes offer a compelling combination of performance, cost-effectiveness, and environmental responsibility. For professionals in pipeline engineering, project procurement, and plant management, choosing FBE-coated pipes is a strategic decision that ensures long-term operational success and sustainability.

High Quality FBE-Coated Steel Pipes

Hebei Longma Group stands as a premier provider of high-quality FBE-coated steel pipes. With advanced production equipment imported from Germany and four independently developed production lines, we ensure top-notch quality and precision in every pipe. Our professional team of over 300 employees, including 60+ technical experts, guarantees innovative solutions tailored to your project needs. Equipped with state-of-the-art testing facilities, including ultrasonic flaw detectors and industrial X-ray systems, we maintain rigorous quality control throughout production. We pride ourselves on fast delivery, completing standard thickness steel pipes in as little as 7 days. Our comprehensive certifications, including API 5L and ISO 9001, reflect our commitment to excellence. Thanks to our integrated production model and strategic partnerships, we offer competitive pricing without compromising on quality. For superior fusion bonded epoxy coated steel pipes that meet the highest industry standards, contact us at info@longma-group.com.