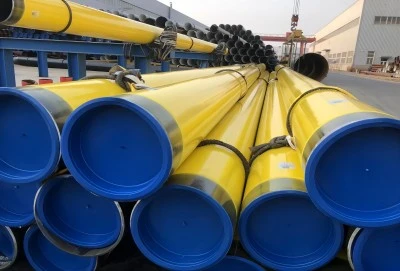

The fusion bonded epoxy coating pipe process is a cutting-edge technology that revolutionizes pipeline protection. This innovative method applies a high-performance epoxy coating to steel pipes, creating a formidable barrier against corrosion and wear. The result? fusion bonded epoxy coated steel pipes that boast exceptional durability and longevity, making them ideal for demanding applications in oil and gas transportation, water supply systems, and industrial manufacturing. Let's dive into the intricate steps and quality control measures that ensure these pipes meet the highest industry standards.

|

|

|

Step-by-Step: Applying FBE to Steel Pipes

Surface Preparation: Abrasive Blasting for Optimal Adhesion

The journey to superior pipe protection begins with meticulous surface preparation. Abrasive blasting, a critical step in the fusion bonded epoxy coating process, ensures optimal adhesion between the steel pipe and the epoxy coating. This technique involves propelling high-velocity abrasive materials against the pipe surface, effectively removing contaminants, rust, and mill scale.

The goal is to achieve a clean, rough surface profile that provides an ideal substrate for the epoxy coating to bond with. Typically, a near-white metal blast cleaning standard (NACE No. 2/SSPC-SP 10) is required, creating a surface roughness of 50-100 microns. This level of preparation significantly enhances the coating's ability to adhere to the pipe, ultimately improving its corrosion resistance and overall performance.

Preheating: Achieving Ideal Temperature for FBE Application

After surface preparation, the steel pipes undergo a preheating process. This crucial step brings the pipe to the optimal temperature for epoxy application, typically between 180°C to 250°C (356°F to 482°F). Precise temperature control is vital, as it directly impacts the coating's ability to melt, flow, and cure properly.

Preheating serves multiple purposes. It removes any remaining moisture from the pipe surface, prevents flash rusting, and ensures the epoxy powder melts and flows evenly upon contact. The right temperature also promotes proper cross-linking of the epoxy molecules, resulting in a strong, uniform coating with excellent adhesion and chemical resistance.

Electrostatic Spraying: Ensuring Even Coating Distribution

The final step in applying fusion bonded epoxy coating to steel pipes involves electrostatic spraying. This advanced technique uses electrically charged epoxy powder particles that are attracted to the grounded, preheated pipe surface. As the powder hits the hot pipe, it immediately melts, flows, and begins to cure, forming a continuous, pinhole-free coating.

Electrostatic spraying offers several advantages. It ensures uniform coating thickness, reduces overspray, and allows for efficient use of coating materials. The process is carefully controlled, with the pipe rotating as it passes through the spray booth to guarantee complete coverage. The result is a smooth, even coating that provides consistent protection across the entire pipe surface.

Quality Control in FBE Coating Application

Thickness Testing: Ensuring Proper Coating CoverageQuality control is paramount in the production of fusion bonded epoxy coated steel pipes. Thickness testing is a crucial aspect of this process, ensuring that the applied coating meets specified requirements. Various methods are employed to measure coating thickness, including magnetic gauges and eddy current devices.

Typically, FBE coatings range from 300 to 600 microns (12 to 24 mils) in thickness. Regular measurements are taken along the pipe's length and circumference to verify consistent coverage. This attention to detail guarantees that every section of the pipe receives adequate protection, enhancing its ability to withstand corrosive environments and mechanical stress.

Holiday Detection: Identifying Coating Defects and Pinholes

Holiday detection is another critical quality control measure in the FBE coating process. A "holiday" refers to any discontinuity in the coating that could expose the underlying steel to corrosion. High-voltage holiday detectors are used to identify these potential weak points.

During this test, the coated pipe is subjected to a specified voltage, typically around 125 volts per mil of coating thickness. Any holidays or pinholes in the coating will allow an electrical current to pass through, triggering an alarm. This process ensures that even microscopic defects are identified and addressed, maintaining the integrity of the protective coating.

Adhesion Testing: Verifying Coating-to-Pipe Bond Strength

The strength of the bond between the fusion bonded epoxy coating and the steel pipe is crucial for long-term performance. Adhesion testing is conducted to verify this bond strength, typically using methods such as the pull-off adhesion test or the knife adhesion test.

In the pull-off test, a loading fixture is glued to the coating surface and force is applied until the coating detaches or a specified force is reached. The knife adhesion test involves making a series of cuts through the coating to the substrate and attempting to lift the coating with a knife blade. These tests ensure that the coating will remain firmly attached to the pipe, even under challenging conditions, providing reliable protection throughout the pipe's service life.

Innovations in FBE Coating Technology

Dual-Layer FBE: Enhanced Protection for Extreme ConditionsAs the demands on pipeline systems continue to grow, so does the need for advanced coating solutions. Dual-layer fusion bonded epoxy (FBE) coatings represent a significant leap forward in pipe protection technology. This innovative approach combines two layers of FBE, each with specific properties, to create a synergistic protective system.

The first layer, often referred to as the primer layer, is designed for optimal adhesion to the steel substrate and provides excellent corrosion resistance. The second layer, or topcoat, is formulated to enhance specific properties such as abrasion resistance, chemical resistance, or high-temperature performance. This dual-layer system offers superior protection in extreme environments, making it ideal for deep-sea pipelines, high-temperature oil transportation, or harsh chemical processing applications.

Nano-Enhanced FBE: Improving Coating Performance and Durability

Nanotechnology has opened new frontiers in coating performance, and fusion bonded epoxy coatings are no exception. Nano-enhanced FBE coatings incorporate microscopic particles that significantly improve the coating's properties. These nanoparticles can enhance various aspects of the coating's performance, including hardness, scratch resistance, and barrier properties.

For instance, the addition of nano-silica particles can improve the coating's resistance to abrasion and impact, extending the life of pipelines in high-wear applications. Nano-clay particles can enhance the coating's barrier properties, providing even better protection against moisture and chemical penetration. These advancements in nano-enhanced FBE coatings are pushing the boundaries of what's possible in pipeline protection, offering unprecedented durability and performance.

The fusion bonded epoxy coating pipe process represents a pinnacle of pipeline protection technology. From meticulous surface preparation to advanced application techniques and rigorous quality control, every step ensures the production of high-performance, durable pipes. As innovations like dual-layer FBE, nano-enhanced coatings, and smart FBE systems continue to evolve, the future of pipeline protection looks brighter than ever. For industries relying on dependable, long-lasting pipeline infrastructure, fusion bonded epoxy coated steel pipes offer an unparalleled solution, combining cutting-edge technology with proven reliability.

Buy Fusion Bonded Epoxy Coated Steel Pipes

When it comes to sourcing high-quality fusion bonded epoxy coated steel pipes, Hebei Longma Group stands out as a leading manufacturer. With advanced production equipment imported from Germany and independently developed technologies, Longma Group ensures top-notch quality in every pipe. Their professional team of over 300 employees, including 60+ technical experts, guarantees expertise in every aspect of production. Comprehensive testing facilities, including ultrasonic flaw detectors and industrial X-ray equipment, ensure rigorous quality control. Longma Group offers fast delivery, with standard thickness pipes ready in as little as 7 days. They hold complete certifications, including API 5L, ISO 9001, and ISO 14001, meeting international standards. Thanks to stable raw material partnerships and an integrated production model, Longma Group maintains competitive pricing without compromising on quality. For reliable steel pipes that meet your project's demands, contact us at info@longma-group.com.