The oil and gas industry has been undergoing significant transformations in recent years, with technological advancements playing a crucial role in enhancing efficiency, safety, and sustainability. One of the most notable innovations in this sector is the development and widespread adoption of API line pipes. These high-performance pipes are revolutionizing oil and gas pipeline systems, offering numerous benefits that are reshaping the energy transportation landscape.

|

|

|

Enhanced Durability and Longevity: The Backbone of Modern Pipeline Systems

API line pipes have emerged as the backbone of modern pipeline systems, primarily due to their exceptional durability and longevity. These pipes are engineered to withstand extreme conditions, including high pressures, corrosive environments, and temperature fluctuations, which are common challenges in oil and gas transportation.

The superior strength of API line pipes is attributed to their advanced manufacturing processes and stringent quality control measures. The American Petroleum Institute (API) sets rigorous standards for these pipes, ensuring they meet or exceed industry requirements for mechanical properties, chemical composition, and dimensional tolerances. This results in pipes that can resist deformation, cracking, and fatigue, even under the most demanding operational conditions.

Furthermore, API line pipes are often coated with specialized materials that provide additional protection against corrosion and abrasion. These coatings can significantly extend the lifespan of the pipes, reducing the need for frequent replacements and minimizing the risk of leaks or failures. As a result, pipeline operators can enjoy reduced maintenance costs and improved operational reliability over the long term.

The enhanced durability of API line pipes also translates to improved safety for workers and surrounding communities. By reducing the likelihood of pipe failures and leaks, these pipes help minimize the risk of accidents, environmental contamination, and service disruptions. This not only protects human lives and ecosystems but also helps companies avoid costly legal and reputational damages associated with pipeline incidents.

Increased Efficiency in Oil and Gas Transportation: Streamlining Energy Delivery

API line pipes are playing a pivotal role in increasing the efficiency of oil and gas transportation systems. Their advanced design and material properties allow for higher flow rates and reduced pressure losses, enabling pipeline operators to transport larger volumes of oil and gas over greater distances with less energy consumption.

One of the key factors contributing to this improved efficiency is the smooth internal surface of API line pipes. The pipes are manufactured with precise dimensional control, resulting in a uniform internal diameter and minimal surface roughness. This smooth surface reduces friction between the flowing fluids and the pipe walls, allowing for more efficient fluid movement and reduced pumping requirements.

Additionally, API line pipes can be designed to accommodate higher operating pressures compared to conventional pipes. This capability allows pipeline operators to increase the throughput of their systems without necessarily expanding the physical infrastructure. By transporting more oil or gas through the same pipeline diameter, companies can optimize their existing assets and defer costly capacity expansion projects.

The efficiency gains provided by API line pipes also extend to installation and maintenance processes. Many modern line pipes feature innovative joint designs that facilitate faster and more reliable connections. These designs can include threaded connections, welded joints, or mechanical couplings that are engineered for quick assembly while maintaining structural integrity. As a result, pipeline construction and repair times can be significantly reduced, minimizing downtime and associated costs.

Moreover, the use of API line pipes enables the implementation of advanced monitoring and control systems. These pipes can be equipped with sensors and smart technologies that provide real-time data on flow rates, pressure, temperature, and other critical parameters. This wealth of information allows operators to optimize pipeline performance, detect potential issues before they escalate, and implement predictive maintenance strategies.

Environmental Sustainability: Reducing the Carbon Footprint of Energy Transportation

As the global focus on environmental sustainability intensifies, API line pipes are emerging as a key component in reducing the carbon footprint of energy transportation. These pipes contribute to environmental protection through various mechanisms, including improved energy efficiency, reduced methane emissions, and enhanced leak detection capabilities.

The superior efficiency of API line pipes, as discussed earlier, directly translates to reduced energy consumption in pipeline operations. By minimizing pressure losses and enabling higher flow rates, these pipes allow operators to transport oil and gas using less pumping power. This reduction in energy consumption leads to lower greenhouse gas emissions associated with pipeline operations, contributing to the industry's efforts to mitigate climate change.

Furthermore, the enhanced durability and corrosion resistance of API line pipes play a crucial role in preventing leaks and spills. Methane emissions from pipeline leaks are a significant concern in the oil and gas industry, as methane is a potent greenhouse gas. By reducing the likelihood of leaks and failures, API line pipes help minimize fugitive emissions, thereby lowering the overall environmental impact of pipeline systems.

API line pipes also facilitate the integration of renewable energy sources into existing pipeline infrastructure. As the energy sector transitions towards cleaner alternatives, there is growing interest in using pipeline networks to transport hydrogen or other low-carbon fuels. Many API line pipes are designed to be compatible with these alternative energy carriers, enabling a smoother transition to a more sustainable energy mix without requiring extensive infrastructure overhauls.

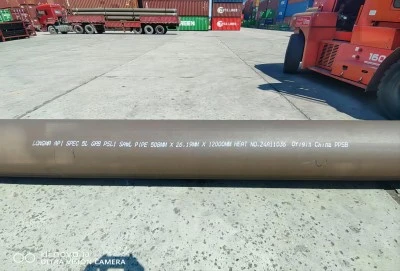

For those seeking to leverage the advantages of line pipes in their pipeline projects, it's crucial to partner with experienced manufacturers who adhere to the highest quality standards. Longma Group is a leading API line pipe manufacturer, offering a wide range of products that meet stringent industry requirements. With grades ranging from B to X80, PSL1 and PSL2 levels, outer diameters from 1/8" to 80", and thicknesses from SCH10 to SCH160, Longma Group provides solutions for diverse pipeline needs. Their commitment to excellence is backed by API 5L, ISO, and QMS certifications, ensuring top-quality products that can revolutionize your oil and gas transportation systems. For more information or to discuss your specific requirements, please contact Longma Group at info@longma-group.com. Their team is dedicated to providing exceptional products and services that can help you stay at the forefront of pipeline technology.