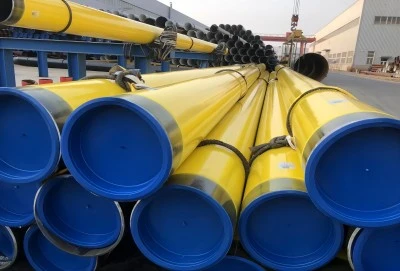

Polyethylene coated steel pipes are renowned for their exceptional durability and longevity in various industrial applications. The lifespan of polyethylene coating on steel pipes typically ranges from 50 to 100 years, depending on several factors such as environmental conditions, installation practices, and maintenance procedures.

|

|

|

Factors affecting polyethylene coating longevity

Environmental conditions impact on PE coating lifespan

The environment in which polyethylene coated steel pipes are installed plays a crucial role in determining their longevity. Harsh conditions can significantly affect the coating's performance and lifespan. For instance, pipes exposed to extreme temperatures, UV radiation, or corrosive substances may experience accelerated degradation of their protective coating.

In regions with high soil acidity or alkalinity, the coating's integrity can be compromised over time. Similarly, areas prone to natural disasters like earthquakes or landslides may subject the pipes to mechanical stress, potentially damaging the coating. Coastal environments present unique challenges due to salt spray and moisture, which can accelerate corrosion if the coating is breached.

Underground installations face different environmental factors compared to above-ground pipes. Soil composition, moisture content, and microbial activity can all impact the coating's effectiveness. However, properly applied polyethylene coatings are designed to withstand these diverse environmental challenges, providing a robust barrier against corrosion and extending the pipe's service life.

Pipe material quality and coating adhesion strength

The quality of the steel pipe substrate and the strength of the coating's adhesion are fundamental factors in determining the longevity of polyethylene coated steel pipes. High-quality steel with consistent surface properties ensures better coating adhesion and reduces the risk of premature coating failure.

Surface preparation is a critical step in the coating process. Proper cleaning, blasting, and priming of the steel surface create an optimal foundation for the polyethylene coating to bond effectively. Advanced coating technologies, such as fusion-bonded epoxy primers followed by polyethylene top coats, enhance adhesion strength and overall coating performance.

The thickness and uniformity of the polyethylene coating also contribute to its durability. Thicker coatings generally offer better protection, but they must be applied consistently to avoid weak points or areas of potential failure. Quality control measures during the coating application process are essential to ensure uniform coverage and optimal adhesion strength.

Installation practices and handling procedures

Proper installation and handling of polyethylene coated steel pipes are crucial for maximizing their lifespan. Careless handling during transportation, storage, or installation can lead to coating damage, compromising the pipe's long-term performance.

Best practices for handling coated pipes include using appropriate lifting equipment, avoiding dragging or rolling pipes on abrasive surfaces, and protecting pipe ends during storage and transportation. During installation, care must be taken to prevent rocks or other sharp objects from damaging the coating as the pipe is lowered into trenches or positioned in place.

Welding and field joint coating are critical aspects of installation that require special attention. Proper heat control during welding and the application of compatible field joint coatings ensure continuity of protection along the entire pipeline. Adhering to industry-standard installation procedures and employing trained personnel are essential for maintaining the integrity of the polyethylene coating throughout the installation process.

Industry standards for PE coating lifespan

NACE and ASTM specifications for coating durabilityThe National Association of Corrosion Engineers (NACE) and the American Society for Testing and Materials (ASTM) have established rigorous standards and specifications for polyethylene coatings on steel pipes. These guidelines ensure that coatings meet minimum performance criteria and provide reliable protection against corrosion.

NACE SP0185 is a key standard that outlines the requirements for extruded polyolefin resin coating systems for underground or submerged pipe. This specification covers aspects such as coating materials, surface preparation, application procedures, and quality control measures. Adherence to these standards is crucial for achieving the expected lifespan of polyethylene coated steel pipes.

ASTM D1248 specifies the requirements for polyethylene plastics molding and extrusion materials, which are relevant to pipe coatings. Other important ASTM standards include ASTM G8 for cathodic disbondment testing and ASTM D4541 for pull-off strength of coatings. These standards help ensure that polyethylene coatings maintain their protective properties over extended periods, contributing to the overall longevity of the coated pipes.

Expected service life of PE-coated steel pipes

The expected service life of polyethylene coated steel pipes, when properly manufactured, installed, and maintained, can exceed 50 years and often reaches 100 years or more. This remarkable longevity is a testament to the effectiveness of polyethylene coatings in protecting steel pipes from corrosion and other forms of degradation.

Factors influencing the expected service life include the specific grade of polyethylene used, coating thickness, environmental conditions, and the effectiveness of supplementary protection measures such as cathodic protection systems. High-density polyethylene (HDPE) coatings, for example, offer superior resistance to chemical attack and mechanical damage, potentially extending the service life even further.

It's important to note that the expected service life is not a fixed value but rather a range based on historical performance data and accelerated testing results. Regular monitoring and maintenance can help identify and address any issues early, potentially extending the actual service life beyond initial expectations.

Performance testing methods for coating longevity

Various performance testing methods are employed to assess and predict the longevity of polyethylene coatings on steel pipes. These tests simulate real-world conditions and stress factors that coatings may encounter during their service life.

Accelerated aging tests expose coated samples to elevated temperatures, UV radiation, or chemical environments to simulate long-term exposure in a compressed timeframe. These tests help predict how the coating will perform over decades of use. Impact resistance tests evaluate the coating's ability to withstand mechanical damage, while adhesion tests measure the strength of the bond between the coating and the steel substrate.

Cathodic disbondment testing is particularly important for assessing the coating's performance in conjunction with cathodic protection systems. This test evaluates the coating's resistance to degradation when subjected to electrical currents similar to those used in cathodic protection. Other critical tests include water absorption, chemical resistance, and thermal cycling, all of which contribute to a comprehensive understanding of the coating's long-term performance capabilities.

Maximizing durability: Maintenance tips for coated pipes

Regular inspection and monitoring techniquesImplementing a robust inspection and monitoring program is crucial for maximizing the durability of polyethylene coated steel pipes. Regular inspections help identify potential issues early, allowing for timely intervention and prevention of more serious problems. Visual inspections can reveal surface damage, while more advanced techniques provide insights into the coating's integrity beneath the surface.

Non-destructive testing methods such as holiday detection, ultrasonic thickness measurement, and infrared thermography are valuable tools for assessing coating condition without compromising its protective properties. These techniques can detect thinning, disbondment, or hidden defects in the coating that may not be visible to the naked eye.

Monitoring soil conditions and corrosion rates in the vicinity of buried pipes provides additional data on the coating's performance. Techniques like soil resistivity measurements and corrosion coupons help assess the corrosivity of the environment and the effectiveness of the coating in resisting corrosion. Regular data collection and trend analysis enable proactive maintenance strategies, ensuring the longevity of polyethylene coated steel pipes.

Cathodic protection systems for enhanced longevity

Cathodic protection systems work in synergy with polyethylene coatings to provide an additional layer of corrosion protection for steel pipes. These systems use electrical currents to suppress the electrochemical reactions that cause corrosion, effectively extending the lifespan of coated pipes, especially in highly corrosive environments.

There are two main types of cathodic protection: impressed current cathodic protection (ICCP) and sacrificial anode cathodic protection. ICCP systems use external power sources to apply a protective current, while sacrificial anode systems rely on the natural potential difference between the steel pipe and a more electrochemically active metal.

Regular monitoring and adjustment of cathodic protection systems are essential to ensure their effectiveness. This includes periodic potential surveys, current output measurements, and inspection of anodes and other system components. Proper integration of cathodic protection with polyethylene coatings can significantly enhance the overall longevity of steel pipes, particularly in challenging environments such as offshore installations or areas with aggressive soil conditions.

Repair and recoating strategies for damaged areas

Despite the durability of polyethylene coatings, damage can occur due to various factors such as mechanical impact, environmental stress, or installation errors. Prompt and effective repair of damaged areas is crucial for maintaining the coating's protective function and preventing localized corrosion.

For minor damage such as small gouges or scratches, field-applied repair coatings or patches can be used to restore the protective barrier. These repairs must be compatible with the original coating and applied according to manufacturer specifications to ensure proper adhesion and performance.

In cases of more extensive damage or when approaching the end of the coating's expected service life, recoating may be necessary. This process involves removing the old coating, preparing the pipe surface, and applying a new polyethylene coating. Advanced techniques such as robotic coating systems can be employed for in-situ recoating of pipelines, minimizing disruption to operations.

Polyethylene coatings on steel pipes offer exceptional longevity, often lasting 50 to 100 years when properly applied and maintained. The durability of these coatings depends on various factors, including environmental conditions, installation practices, and ongoing maintenance. By adhering to industry standards, implementing regular inspection and monitoring programs, and utilizing complementary protection methods like cathodic protection, the lifespan of polyethylene coated steel pipes can be maximized. This longevity translates to reduced maintenance costs, improved operational reliability, and enhanced sustainability for critical infrastructure projects across various industries.

High Quality Polyethylene Coated Steel Pipes: Longma Group

When seeking high-quality polyethylene coated steel pipes for your project, look no further than Hebei Longma Group. Our state-of-the-art production facilities, which include equipment imported from Germany and four independently developed production lines, ensure top-notch quality and consistency. With a professional team of over 300 employees, including 60+ technical experts and an independent equipment research team, we bring unparalleled expertise to every project.

Our comprehensive testing facilities, featuring online ultrasonic automatic flaw detectors and industrial X-ray television, guarantee the highest standards of quality control. We pride ourselves on fast delivery. Our products are backed by complete certifications, including API 5L, ISO 9001, ISO 14001, and more, ensuring compliance with international standards.

Thanks to our long-term partnerships with raw material suppliers, mature production facilities, and rigorous quality control system, we offer competitive pricing without compromising on quality. For inquiries about our pipes or to discuss your project requirements, contact us at info@longma-group.com.