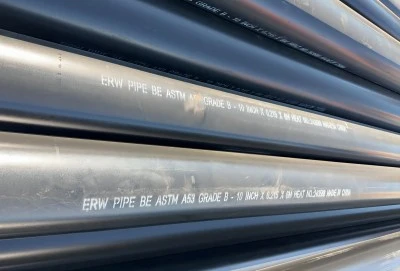

ERW steel pipe, renowned for its structural integrity and versatility, exhibits remarkable strength characteristics that make it a top choice in various industrial applications. The strength of ERW pipe stems from its unique manufacturing process, which involves high-frequency electric resistance welding. This method creates a continuous, high-quality seam along the pipe's length, resulting in a product that boasts impressive tensile strength, pressure resistance, and overall durability. While the exact strength can vary based on factors such as steel grade and wall thickness, ERW pipes generally demonstrate excellent load-bearing capabilities and resistance to both internal and external pressures.

|

|

|

Strength Comparison: ERW vs. Seamless Pipes

Tensile Strength: ERW vs Seamless Steel Pipes

When comparing the tensile strength of ERW and seamless steel pipes, it's essential to understand that both types offer robust performance in various applications. ERW steel pipes, manufactured through electric resistance welding, typically exhibit tensile strengths comparable to their seamless counterparts. The welding process in ERW pipes creates a uniform structure along the seam, often resulting in strengths ranging from 30,000 to 100,000 psi, depending on the steel grade used.

Seamless pipes, produced without welding, are often perceived as having superior strength due to their continuous structure. However, advancements in ERW technology have significantly narrowed this gap. In many cases, ERW pipes can match or even exceed the tensile strength of seamless pipes, particularly in standard grades commonly used in oil and gas transportation.

Pressure Resistance: ERW and Seamless Pipe Performance

Pressure resistance is a critical factor in pipe selection, especially for applications in high-pressure environments. ERW steel pipes have shown impressive capabilities in this area, often matching seamless pipes in their ability to withstand internal pressures. The welding process in ERW pipes, when executed with precision, creates a seam that is as strong as the base metal, allowing these pipes to handle significant pressures without failure.

In practical applications, such as water supply systems or oil transportation, ERW pipes demonstrate excellent pressure resistance. They can withstand working pressures of up to 3,000 psi or more, depending on the pipe's specifications. This performance level makes ERW pipes a cost-effective alternative to seamless pipes in many pressure-critical applications.

Corrosion Resistance: ERW vs Seamless Pipe Durability

Corrosion resistance is another crucial aspect when evaluating pipe strength and longevity. In this regard, ERW steel pipes have made significant strides, offering corrosion resistance comparable to seamless pipes in many environments. The key lies in the quality of the base metal and the welding process.

Modern ERW pipes, especially those made from high-grade steels, exhibit excellent resistance to both internal and external corrosion. The welded seam, often a point of concern, is treated and tested to ensure it matches the corrosion resistance of the pipe body. In aggressive environments, such as offshore platforms or chemical processing plants, ERW pipes with appropriate coatings or linings can provide durability on par with seamless pipes.

Factors Influencing ERW Pipe Strength

Impact of Steel Grade on ERW Pipe StrengthThe steel grade used in manufacturing ERW pipes plays a pivotal role in determining their overall strength and performance. Higher-grade steels, such as those conforming to API 5L X70 or X80 standards, yield pipes with superior tensile strength, yield strength, and toughness. These grades are often preferred in demanding applications like high-pressure gas pipelines or offshore oil transportation.

For instance, ERW pipes made from X70 grade steel can exhibit yield strengths of up to 70,000 psi and tensile strengths exceeding 80,000 psi. This remarkable strength allows for thinner wall thicknesses while maintaining the required pressure ratings, leading to cost savings in material and transportation. The choice of steel grade also influences the pipe's ability to withstand extreme temperatures and resist brittle fracture, crucial factors in many industrial applications.

Wall Thickness and ERW Pipe Durability

Wall thickness is another critical factor that significantly impacts the strength and durability of ERW steel pipes. Thicker walls generally translate to higher pressure ratings and increased resistance to external forces. However, the relationship between wall thickness and strength is not always linear and must be balanced with other considerations such as weight and cost.

In the oil and gas industry, for example, ERW pipes with wall thicknesses ranging from 0.25 inches to over 1 inch are common, depending on the specific application and operating conditions. Thicker walls provide enhanced protection against internal pressure, external loads, and potential corrosion, but they also increase the pipe's weight and material costs. Engineers must carefully consider the optimal wall thickness to achieve the required strength while maintaining efficiency in transportation and installation.

Welding Quality's Effect on ERW Pipe Performance

The quality of the welding process is paramount in determining the overall strength and reliability of ERW steel pipes. High-frequency welding, the method used in ERW pipe production, creates a continuous seam that, when executed correctly, is as strong as the base metal. The weld quality directly affects the pipe's ability to withstand pressure, tensile forces, and fatigue stress.

Advanced welding technologies and stringent quality control measures ensure that modern ERW pipes have welds that are virtually indistinguishable from the pipe body in terms of strength and durability. Post-weld heat treatment and advanced inspection techniques, such as ultrasonic testing, further enhance the weld quality. A high-quality weld not only contributes to the pipe's overall strength but also improves its resistance to corrosion and stress corrosion cracking, critical factors in long-term pipe performance.

Testing Methods for ERW Pipe Durability

Hydrostatic Pressure Testing for ERW PipesHydrostatic pressure testing is a crucial method for assessing the strength and integrity of ERW steel pipes. This test involves filling the pipe with water and pressurizing it to a level significantly above its designed operating pressure. The test typically lasts for a specified period, during which the pipe is closely monitored for any signs of leakage, deformation, or failure.

For ERW pipes used in oil and gas applications, hydrostatic tests often involve pressures up to 1.5 times the maximum allowable operating pressure. This rigorous testing ensures that the pipe can withstand the stresses it will encounter in real-world conditions. The results of hydrostatic tests provide valuable data on the pipe's pressure resistance, weld integrity, and overall structural soundness, instilling confidence in its performance under demanding conditions.

Non-Destructive Testing Techniques for ERW Pipes

Non-destructive testing (NDT) techniques play a vital role in evaluating the quality and durability of ERW steel pipes without compromising their structural integrity. These methods include ultrasonic testing, radiographic inspection, and magnetic particle inspection. Ultrasonic testing, in particular, is highly effective in detecting internal flaws, weld defects, and wall thickness variations in ERW pipes.

Advanced NDT technologies, such as automated ultrasonic testing systems, allow for 100% inspection of ERW pipes during production. These systems can detect minute defects that might be missed by conventional methods, ensuring that only pipes meeting the highest quality standards are approved for use. The data gathered from NDT helps in assessing the long-term reliability of ERW pipes and provides crucial information for quality control and process improvement.

Fatigue Testing: Assessing ERW Pipe Longevity

Fatigue testing is essential for evaluating the long-term durability of ERW pipes, especially in applications involving cyclic loading or pressure fluctuations. This type of testing subjects pipe samples to repeated stress cycles, simulating the conditions they might encounter over years of service. The results provide insights into the pipe's resistance to fatigue failure and its expected service life under various operating conditions.

For ERW steel pipes used in offshore platforms or high-pressure gas transmission, fatigue testing often involves millions of stress cycles. The data from these tests help engineers determine safe operating limits and maintenance schedules. Advanced fatigue testing methods, such as full-scale resonance testing, offer even more accurate predictions of pipe performance under real-world conditions, further validating the strength and reliability of ERW pipes in critical applications.

ERW steel pipes have proven their mettle in various demanding applications, showcasing strength characteristics that often rival or surpass those of seamless pipes. Their impressive tensile strength, pressure resistance, and corrosion durability make them a preferred choice in industries ranging from oil and gas to water supply systems. The strength of ERW pipes is a result of advanced manufacturing techniques, careful material selection, and rigorous quality control processes. As technology continues to evolve, ERW pipes are likely to find even broader applications, reinforcing their position as a strong, reliable, and cost-effective solution for industrial piping needs.

ERW Pipes Supplier

When it comes to sourcing high-quality ERW steel pipes for your projects, Hebei Longma Group stands out as a premier manufacturer and supplier. Our state-of-the-art production facilities, which include equipment imported from Germany and four independently developed production lines, ensure the highest standards of quality and efficiency. With a team of over 300 employees, including more than 60 technical experts and an independent equipment research team, we have the expertise to meet your specific requirements.

Our comprehensive testing facilities, featuring online ultrasonic automatic flaw detectors and industrial X-ray television, guarantee the integrity of every pipe we produce. We pride ourselves on fast delivery, with the ability to complete production of standard thickness steel pipes in as little as 7 days. Our products are backed by complete certifications, including API 5L, ISO 9001, ISO 14001, and more, ensuring compliance with international standards.

At Hebei Longma Group, we offer competitive pricing without compromising on quality, thanks to our long-term partnerships with raw material suppliers and our integrated production model. For more information on our ERW pipes or to discuss your project needs, contact us at info@longma-group.com. Our team is ready to provide you with expert advice and tailored solutions for your piping requirements.