Controlling the verticality of welded steel pipe is crucial for ensuring structural integrity and optimal performance in various applications. To achieve proper alignment, manufacturers employ advanced techniques, precise equipment, and rigorous quality control measures. By focusing on material properties, welding processes, and environmental factors, industries can produce high-quality welded pipes that meet stringent verticality requirements for oil and gas transportation, water supply systems, and offshore platform construction.

|

|

|

Key factors affecting pipe verticality

Material properties and pipe dimensions

The characteristics of the steel used in pipe manufacturing play a significant role in maintaining verticality. High-strength, low-alloy steels offer improved resistance to deformation, ensuring better alignment during and after the welding process. The pipe's diameter-to-thickness ratio also influences its ability to maintain straightness, with thicker walls generally providing better stability.

Moreover, the chemical composition of the steel affects its weldability and thermal expansion properties. Pipes with uniform composition are less likely to experience uneven cooling and subsequent warping. Manufacturers must carefully select materials that balance strength, weldability, and dimensional stability to achieve optimal verticality in the final product.

Welding techniques and equipment precision

The choice of welding method and the precision of the equipment used are critical in controlling pipe verticality. Advanced welding techniques, such as submerged arc welding (SAW) for large-diameter pipes, offer excellent control over heat input and weld penetration. This precision helps minimize distortion and maintains the pipe's straightness throughout the welding process.

State-of-the-art welding equipment with automated controls ensures consistent weld quality and reduces human error. Computerized welding systems can adjust parameters in real-time, compensating for variations in material properties or environmental conditions that might affect verticality.

Environmental conditions during manufacturing

The manufacturing environment significantly impacts pipe verticality. Temperature fluctuations can cause uneven thermal expansion and contraction, leading to distortion. Humidity levels affect cooling rates and can influence the final shape of the welded pipe. To mitigate these issues, modern production facilities maintain strict climate control and employ specialized cooling techniques to ensure uniform solidification of the weld and surrounding material.

Additionally, proper storage and handling of pipes during and after production are essential. Stacking methods and support systems must be designed to prevent sagging or bending, particularly for larger diameter pipes. By controlling these environmental factors, manufacturers can significantly improve the verticality of their welded steel pipes.

Advanced techniques for vertical alignment

Laser-guided welding systems for LSAW pipesLongitudinal Submerged Arc Welded (LSAW) pipes benefit greatly from laser-guided welding systems. These advanced setups use high-precision lasers to continuously monitor and adjust the welding path, ensuring perfect alignment along the pipe's length. The laser guidance system provides real-time feedback to the welding equipment, allowing for immediate corrections to maintain verticality.

This technology is particularly valuable for large-diameter pipes used in high-pressure applications, such as offshore oil and gas pipelines. The extreme accuracy of laser-guided systems results in consistently straight welds, reducing the need for post-weld straightening and improving overall pipe quality.

Computer-controlled ERW pipe production

Electric Resistance Welded (ERW) pipe production has been revolutionized by computer-controlled systems. These sophisticated setups manage every aspect of the welding process, from feed rate to weld current, ensuring optimal conditions for maintaining pipe verticality. Advanced sensors continuously monitor the pipe's shape and position, making micro-adjustments to the welding parameters as needed.

The computer control extends beyond the welding stage, encompassing the entire production line. This includes precise control of the forming rollers that shape the flat steel into a tubular form, as well as the cooling and cutting processes. By maintaining tight control over each step, these systems significantly improve the consistency and verticality of ERW pipes.

Real-time monitoring and adjustment technologies

Cutting-edge pipe manufacturing facilities employ real-time monitoring systems that use a combination of sensors, cameras, and artificial intelligence to continuously assess pipe verticality throughout the production process. These systems can detect even minute deviations from the desired straightness and initiate corrective actions immediately.

For instance, advanced optical measurement systems can scan the entire length of a pipe in seconds, creating a detailed 3D model that highlights any areas of concern. This data is then used to make precise adjustments to the production parameters or to flag pipes that require additional straightening procedures. By catching and correcting issues early, these technologies significantly improve the overall quality and verticality of welded steel pipes.

Measuring and correcting verticality deviations

Non-destructive testing methods for verticalityEnsuring the verticality of welded steel pipes requires sophisticated non-destructive testing (NDT) methods. Advanced ultrasonic testing techniques, such as phased array ultrasonics, allow for detailed inspection of the pipe's internal structure and geometry without causing any damage. These methods can detect even slight deviations from perfect straightness, enabling manufacturers to identify and address verticality issues promptly.

Laser-based measurement systems offer another powerful tool for assessing pipe verticality. These systems can rapidly scan the entire length of a pipe, creating a highly accurate 3D profile. This data allows for precise quantification of any bends, twists, or other deviations from the ideal straight form. By combining multiple NDT methods, manufacturers can gain a comprehensive understanding of a pipe's verticality and overall quality.

Corrective measures for out-of-plumb steel pipes

When verticality deviations are detected, several corrective measures can be employed. For minor misalignments, controlled heating and cooling processes can be used to induce slight bending, bringing the pipe back into proper alignment. This technique, often referred to as "heat straightening," requires precise control of temperature and cooling rates to avoid introducing new stresses or altering the pipe's material properties.

For more significant deviations, mechanical straightening methods may be necessary. Hydraulic presses or roller straightening machines can apply carefully calculated forces to reshape the pipe. These processes must be carried out with extreme care to avoid damaging the pipe or compromising its structural integrity. In some cases, a combination of heat treatment and mechanical straightening may be used to achieve optimal results.

Quality control standards for vertical pipe alignment

The oil and gas industry, along with other sectors requiring high-performance piping, adheres to stringent quality control standards for vertical pipe alignment. These standards, such as those outlined in API 5L and ISO 3183, specify acceptable tolerances for straightness and out-of-roundness. Compliance with these standards is crucial for ensuring the safety and efficiency of pipeline systems.

Quality control processes typically involve multiple inspection points throughout the manufacturing process. This includes initial checks on raw materials, in-process monitoring during welding and forming, and final inspections of the completed pipes. Advanced measurement technologies, such as laser-based systems and computerized gauges, are used to verify that each pipe meets the required verticality specifications before it leaves the production facility.

Controlling the verticality of welded steel pipes is a complex process that requires a combination of advanced technologies, skilled craftsmanship, and rigorous quality control. By focusing on key factors such as material properties, welding techniques, and environmental conditions, manufacturers can produce pipes that meet the exacting standards required for critical applications in the oil and gas, water supply, and construction industries. The ongoing development of new technologies and methodologies continues to improve our ability to create straighter, more reliable welded steel pipes, ensuring safer and more efficient infrastructure for years to come.

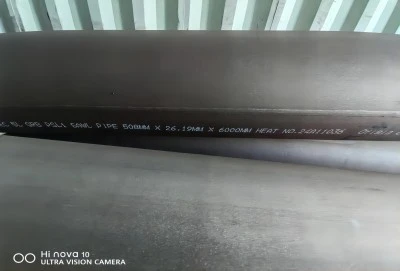

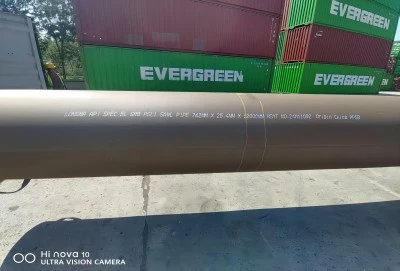

Welded Steel Pipe For Sale

Hebei Longma Group is your trusted source for high-quality welded pipes. Our state-of-the-art production facilities, which include equipment imported from Germany and four independently developed production lines, ensure superior product quality and consistency. With a team of over 300 skilled employees, including 60+ technical experts and an independent research team, we're at the forefront of pipe manufacturing technology.

Our comprehensive testing facilities, featuring online ultrasonic automatic flaw detectors and industrial X-ray equipment, guarantee that every pipe meets the highest standards of quality and verticality. We pride ourselves on fast delivery, with the ability to complete production of standard thickness pipes in as little as 7 days. Our products are backed by a complete range of certifications, including API 5L, ISO 9001, ISO 14001, and more.

Thanks to our long-term partnerships with raw material suppliers and our integrated production model, we offer competitive pricing without compromising on quality. For more information about our welded steel pipe offerings or to discuss your specific project requirements, contact us at info@longma-group.com.