Identifying genuine ASTM A53 Gr B steel pipe is crucial for ensuring the safety and reliability of your industrial projects. This high-quality carbon steel pipe is widely used in oil and gas transportation, water supply systems, and structural applications. To verify the authenticity of ASTM A53 Gr B pipe, you'll need to examine key markings, conduct material testing, and be aware of potential red flags in the sourcing process. Let's dive into the essential steps for identifying genuine ASTM A53 Gr B steel pipe and safeguarding your projects from substandard materials.

|

|

|

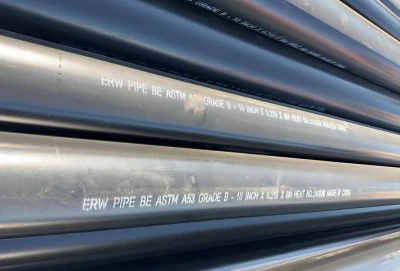

Key Markings: Decoding ASTM A53 Gr B Labels

ASTM A53 Gr B Pipe MarkingsGenuine ASTM A53 Gr B steel pipes come with specific markings that provide valuable information about their properties and origin. These markings are typically stenciled or stamped directly onto the pipe surface. When examining the pipe, look for the following key details:

- ASTM A53: This indicates compliance with the ASTM A53 standard.

- Grade B: Specifies the grade of the steel pipe.

- Seamless or ERW: Indicates the manufacturing process (seamless or electric resistance welded).

- Nominal pipe size and schedule: Provides information about the pipe dimensions.

- Heat number: A unique identifier for the batch of steel used in production.

Understanding these markings is essential for verifying the pipe's authenticity and ensuring it meets your project requirements.

Interpreting Manufacturer's Stamps on A53 Gr B Pipes

In addition to standard markings, manufacturers often include their own stamps or logos on ASTM A53 Gr B pipes. These stamps can provide valuable information about the pipe's origin and quality. Pay attention to:

- Manufacturer's name or logo: Identifies the company that produced the pipe.

- Country of origin: Indicates where the pipe was manufactured.

- Production date: Helps determine the age of the pipe.

- Certification marks: May include symbols from third-party testing or certification bodies.

Familiarize yourself with reputable manufacturers' stamps to better identify genuine ASTM A53 Gr B pipes.

Color Coding: A Quick Guide for A53 Gr B Identification

While not a definitive method, color coding can provide a quick visual reference for identifying ASTM A53 Gr B pipes. Common color codes include:

- Green band: Often used to indicate ASTM A53 Gr B pipe.

- Blue band: May signify API 5L Grade B pipe, which has similar properties to ASTM A53 Gr B.

- Red band: Sometimes used for fire protection systems using ASTM A53 Gr B pipe.

Remember that color coding practices may vary between manufacturers and regions, so always verify with other identification methods.

Material Testing: Verifying A53 Gr B Specifications

Chemical Composition Analysis of ASTM A53 Gr B SteelTo ensure the authenticity of ASTM A53 Gr B steel pipe, conducting a chemical composition analysis is crucial. This test verifies that the pipe meets the standard's requirements for various elements. Key components to check include:

- Carbon (C): 0.30% maximum

- Manganese (Mn): 1.20% maximum

- Phosphorus (P): 0.05% maximum

- Sulfur (S): 0.045% maximum

X-ray fluorescence (XRF) analyzers or optical emission spectrometers are commonly used for on-site chemical analysis. These tools provide quick and accurate results, helping you verify the pipe's composition without destructive testing.

Mechanical Property Tests for A53 Gr B Pipe Validation

ASTM A53 Gr B steel pipes must meet specific mechanical property requirements. Conducting these tests helps validate the pipe's performance capabilities:

- Tensile strength: Minimum 60,000 psi (415 MPa)

- Yield strength: Minimum 35,000 psi (240 MPa)

- Elongation: Minimum 0.5 inch (12.7 mm) in 2 inches (50.8 mm)

These tests typically require specialized equipment and may need to be performed in a laboratory setting. However, portable hardness testers can provide an initial indication of the pipe's strength properties on-site.

Non-Destructive Testing Methods for A53 Gr B Pipes

Non-destructive testing (NDT) methods are valuable for assessing ASTM A53 Gr B pipes without compromising their integrity. Common NDT techniques include:

- Ultrasonic testing: Detects internal flaws and measures wall thickness.

- Magnetic particle inspection: Identifies surface and near-surface defects.

- Radiographic testing: Reveals internal defects using X-rays or gamma rays.

These methods help ensure the pipe's structural integrity and compliance with ASTM A53 Gr B standards. Regular NDT inspections throughout the pipe's lifecycle can help maintain its reliability and safety in critical applications.

Avoiding Counterfeits: Red Flags in Pipe Sourcing

Spotting Fake Certificates: ASTM A53 Gr B DocumentationWhen sourcing ASTM A53 Gr B steel pipes, be vigilant about the documentation provided. Authentic certificates should include:

- Mill Test Report (MTR) or Material Test Certificate (MTC)

- Heat number matching the pipe markings

- Detailed chemical composition and mechanical property results

- Manufacturer's name and contact information

- Authorized signature and stamp

Watch out for red flags such as inconsistencies in data, poor-quality printing, or missing critical information. Verify certificates with the issuing body if you have any doubts about their authenticity.

Price vs. Quality: Balancing A53 Gr B Pipe Procurement

While cost is an important factor in pipe procurement, extremely low prices can be a warning sign of counterfeit or substandard ASTM A53 Gr B pipes. Consider the following when evaluating prices:

- Compare quotes from multiple reputable suppliers

- Be wary of prices significantly below market average

- Factor in long-term costs, including potential replacements and safety risks

- Consider the supplier's reputation and certification status

Remember that investing in quality ASTM A53 Gr B pipes can lead to improved safety, longer service life, and reduced maintenance costs in the long run.

Trusted Suppliers: Sourcing Authentic ASTM A53 Gr B Pipes

To minimize the risk of encountering counterfeit ASTM A53 Gr B pipes, focus on building relationships with trusted suppliers. Look for suppliers who:

- Have a proven track record in the industry

- Maintain relevant certifications (e.g., ISO 9001, API Q1)

- Offer full traceability of their products

- Provide comprehensive documentation and support

- Are willing to accommodate site visits and audits

Establishing long-term partnerships with reliable suppliers can help ensure a consistent supply of genuine ASTM A53 Gr B pipes for your projects.

Identifying genuine ASTM A53 Gr B steel pipe requires a combination of visual inspection, material testing, and careful sourcing practices. By understanding key markings, verifying material properties, and working with trusted suppliers, you can ensure the authenticity and quality of the pipes used in your projects. Remember that the extra effort invested in proper identification and verification can lead to improved safety, reliability, and cost-effectiveness in your industrial applications. Stay vigilant and prioritize quality to protect the integrity of your infrastructure and the safety of your operations.

Longma Group ASTM A53 Gr B Steel Pipes

For high-quality ASTM A53 Gr B steel pipes, consider Hebei Longma Group. Our advanced production equipment, imported from Germany, ensures top-notch quality. With over 300 employees, including 60+ technical experts, we offer unparalleled expertise. Our comprehensive testing facilities, including ultrasonic flaw detectors and X-ray equipment, guarantee product integrity. We provide fast delivery, with standard thickness pipes ready in just 7 days. Our certifications include API 5L, ISO 9001, ISO 14001, and more. Thanks to our stable raw material partnerships and efficient production model, we offer competitive pricing without compromising quality. For authentic ASTM A53 Gr B pipes that meet your project needs, contact us at info@longma-group.com.