Identifying whether a pipe is seamless or ERW (Electric Resistance Welded) is crucial for engineers and procurement managers in the oil and gas industry. ERW pipes are manufactured by rolling flat steel into a cylindrical shape and welding the seam, while seamless pipes are produced without any welding. The key to distinguishing between the two lies in visual inspection and specialized testing methods.

|

|

|

Visual Inspection Techniques for Pipe Identification

Examining Surface Characteristics of ERW vs Seamless Pipes

When it comes to visual inspection, the surface characteristics of ERW and seamless pipes can provide valuable clues. ERW pipes often exhibit a subtle line running along the length of the pipe, which is the weld seam. This line may be slightly raised or depressed, depending on the manufacturing process. In contrast, seamless pipes have a more uniform surface texture without any visible seam.

However, it's important to note that modern manufacturing techniques have made weld seams less noticeable in high-quality ERW pipes. This is why a thorough examination is necessary, often requiring the use of magnifying tools or specialized lighting to detect subtle surface variations.

Spotting Weld Seams: Key Indicators of ERW Pipes

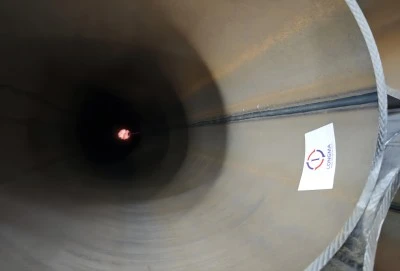

The weld seam is the most definitive visual indicator of an ERW pipe. To spot it, rotate the pipe slowly under good lighting conditions. Look for a straight line running the entire length of the pipe. In some cases, you might notice a slight color difference along the seam due to the heat-affected zone created during the welding process.

For pipes with external coatings, the seam might be more challenging to detect. In such cases, examining the pipe ends can be helpful. The weld line often appears as a slight discoloration or a thin, straight line across the pipe's cross-section.

Analyzing Pipe End Features for Seamless Identification

Seamless pipes have distinct end features that can aid in identification. When examining the pipe end, look for a uniform grain structure across the entire cross-section. Seamless pipes typically show a consistent pattern from the outer diameter to the center.

Additionally, seamless pipes often have a slight variation in wall thickness around the circumference due to the manufacturing process. This variation is usually minimal and requires precise measurement tools to detect. erw pipes, on the other hand, tend to have more consistent wall thickness due to the rolling process used in their production.

Testing Methods: Seamless vs ERW Pipes

Non-Destructive Testing: Ultrasonic and Eddy Current MethodsNon-destructive testing (NDT) methods are essential for accurately identifying pipe types without damaging the material. Ultrasonic testing is particularly effective for distinguishing between ERW and seamless pipes. This method uses high-frequency sound waves to detect internal flaws and material inconsistencies.

In ERW pipes, ultrasonic testing can reveal the weld line as a distinct acoustic signature. Seamless pipes, however, show a more uniform acoustic response across the entire pipe body. Eddy current testing is another valuable NDT method, especially for detecting surface and near-surface defects. This technique can highlight the subtle differences in electrical conductivity near the weld seam of ERW pipes.

Hydrostatic Pressure Tests for Pipe Strength Comparison

Hydrostatic pressure testing is crucial for assessing the overall strength and integrity of both ERW and seamless pipes. While this test doesn't directly identify the pipe type, it can reveal performance differences that may be characteristic of each manufacturing method.

ERW pipes typically show uniform pressure resistance along their length, except potentially at the weld seam. Seamless pipes often exhibit more consistent pressure resistance throughout. However, it's important to note that high-quality ERW pipes can perform comparably to seamless pipes in these tests, making this method less definitive for identification purposes.

Metallographic Examination: Microstructure Differences

Metallographic examination involves analyzing the microstructure of the pipe material. This method requires taking a small sample from the pipe and examining it under a microscope. In erw pipes, the microstructure near the weld seam often shows a heat-affected zone with slightly different grain structures compared to the rest of the pipe body.

Seamless pipes, conversely, display a more uniform microstructure throughout. This method provides definitive evidence of pipe type but is invasive and typically reserved for situations where non-destructive methods are inconclusive or when detailed material analysis is required for critical applications.

Common Misconceptions in Pipe Identification

Debunking Myths: ERW Pipe Strength vs Seamless PipesA prevalent misconception in the industry is that seamless pipes are inherently stronger than ERW pipes. While this might have been true in the past, modern manufacturing techniques have significantly narrowed the gap. High-quality pipes can now match or even exceed the strength of seamless pipes in many applications.

The strength of a pipe depends more on the quality of the raw material and the manufacturing process rather than whether it's ERW or seamless. Both types can meet stringent industry standards when properly manufactured. It's crucial for engineers and procurement managers to evaluate pipes based on their specific performance characteristics rather than making assumptions based on the manufacturing method alone.

Understanding Manufacturing Processes: ERW vs Seamless

Another common misconception is that the manufacturing process for ERW pipes is less sophisticated than that for seamless pipes. In reality, both processes involve advanced technology and precision engineering. Pipe production has evolved significantly, incorporating high-frequency welding and advanced quality control measures.

Seamless pipe manufacturing, while different, isn't necessarily more advanced. Each process has its own complexities and advantages. Understanding these processes helps in appreciating the unique qualities of each pipe type and selecting the most appropriate option for specific project requirements.

Cost-Effectiveness: Comparing ERW and Seamless Options

The belief that seamless pipes are always more expensive than erw pipes is another misconception. While seamless pipes often come with a higher price tag due to their manufacturing process, the cost-effectiveness of each type depends on various factors including material grade, diameter, and wall thickness.

For large-diameter pipes or those requiring thinner walls, pipes can be more cost-effective without compromising on quality. It's essential to consider the total cost of ownership, including installation, maintenance, and expected lifespan, rather than just the initial purchase price when comparing ERW and seamless options.

Identifying whether a pipe is seamless or ERW requires a combination of visual inspection and specialized testing methods. While visual cues like weld seams can be indicative, advanced manufacturing techniques often necessitate more sophisticated identification approaches. Non-destructive testing methods such as ultrasonic and eddy current testing provide reliable results without compromising pipe integrity. Understanding the strengths and limitations of both ERW and seamless pipes is crucial for making informed decisions in pipeline projects. As technology advances, the performance gap between these pipe types continues to narrow, emphasizing the importance of evaluating each option based on specific project requirements rather than generalizations.

ERW Pipe For Sale

At Hebei Longma Group, we offer high-quality pipes suitable for various industrial applications. Our state-of-the-art production facilities, imported from Germany, ensure top-notch quality and consistency in every pipe we manufacture. With a team of over 300 skilled employees, including 60+ technical experts, we guarantee precision and innovation in our products. Our comprehensive testing facilities, featuring ultrasonic flaw detectors and industrial X-ray equipment, ensure that every pipe meets the highest industry standards. We pride ourselves on fast delivery, with standard thickness pipes ready in as little as 7 days. Our pipes come with complete certification, including API 5L and ISO 9001, meeting global quality benchmarks. Thanks to our efficient production model and strong supplier relationships, we offer competitive pricing without compromising on quality. For inquiries about our ERW pipes or other products, contact us at info@longma-group.com.