When it comes to steel pipes used in the oil and gas industry, API 5L Grade B is a commonly specified material. However, there's often confusion about whether this grade falls under the category of carbon steel. In this comprehensive guide, we'll explore the classification of API 5L Grade B pipe, its key differences from ordinary carbon steel, and why it's not typically referred to as "carbon steel" despite its composition. Let's dive into the intricacies of this important material specification.

|

|

|

Clarification of Material Classification

To understand the classification of API 5L Grade B, it's essential to first clarify what we mean by "carbon steel" and how materials are categorized in the steel industry.

Carbon steel is generally defined as an alloy of iron and carbon, where carbon is the primary alloying element. The American Iron and Steel Institute (AISI) classifies carbon steels as those containing up to 2.0% carbon and only residual amounts of other elements. However, in practice, most carbon steels contain less than 1.0% carbon.

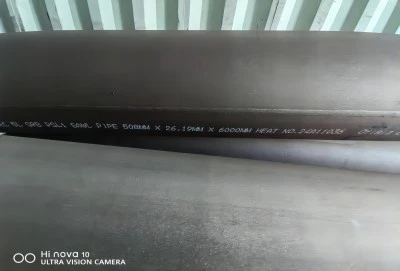

API 5L Grade B pipe, on the other hand, is a specification for line pipe used in oil and gas transportation. It's part of the API 5L standard, which covers seamless and welded steel line pipes. While API 5L Grade B does contain carbon as a primary element, its composition and properties are more specifically defined than generic carbon steel.

The chemical composition of API 5L Grade B typically includes:

- Carbon: 0.22% max

- Manganese: 1.20% max

- Phosphorus: 0.025% max

- Sulfur: 0.015% max

- Other elements in specified amounts

Based on this composition, API 5L Grade B could technically be considered a low-carbon steel. However, its classification is more nuanced due to its specific application and performance requirements.

Key Differences Between API 5L Grade B and Ordinary Carbon Steel

While API 5L Grade B shares some similarities with ordinary carbon steel, there are several key differences that set it apart:

- Composition Control: API 5L Grade B has tighter controls on its chemical composition compared to ordinary carbon steel. The limits on elements like carbon, manganese, phosphorus, and sulfur are specifically defined to ensure consistent performance in pipeline applications.

- Mechanical Properties: API 5L Grade B has specific requirements for yield strength, tensile strength, and elongation. These properties are crucial for its intended use in pipelines and are more precisely defined than those of general carbon steel grades.

- Manufacturing Process: API 5L welded pipe, including Grade B, is produced using specific welding methods such as ERW (Electric Resistance Welding) or LSAW (Longitudinal Submerged Arc Welding). These processes are tailored to ensure the pipe meets the stringent requirements of the oil and gas industry.

- Quality Control: The production of API 5L Grade B pipe involves rigorous quality control measures, including non-destructive testing and hydrostatic testing, which may not be as extensive for ordinary carbon steel products.

- Intended Application: While ordinary carbon steel can be used in various applications, API 5L Grade B is specifically designed and manufactured for use in oil and gas pipelines, where safety and reliability are paramount.

- Standardization: API 5L Grade B adheres to the API 5L standard, which is internationally recognized in the oil and gas industry. Ordinary carbon steel may follow different standards depending on its intended use.

These differences highlight why API 5L Grade B is considered a distinct category within the broader spectrum of steel materials. Its specific properties and manufacturing requirements set it apart from general-purpose carbon steel.

Why is API 5L Grade B Not Called "Carbon Steel"?

Despite its carbon content, API 5L Grade B is not typically referred to as "carbon steel" for several reasons:

- Specificity: The term "API 5L Grade B" provides more specific information about the material's properties, manufacturing process, and intended use than the broad term "carbon steel."

- Industry Recognition: In the oil and gas industry, using the API 5L designation immediately communicates that the material meets specific standards for pipeline applications.

- Performance Expectations: Referring to the material as API 5L Grade B sets clear expectations for its performance characteristics, which are crucial in high-stakes applications like oil and gas transportation.

- Quality Assurance: The API 5L designation implies that the material has undergone specific quality control processes and meets stringent industry requirements.

- Differentiation: Using the API 5L Grade B pipe designation helps differentiate this material from other carbon steel grades that may not be suitable for pipeline applications.

- Global Standardization: The API 5L standard is internationally recognized, making it easier for global industry participants to communicate material requirements consistently.

It's important to note that while API 5L Grade B is not typically called "carbon steel," it does fall within the broader category of low-alloy steels. This classification acknowledges its carbon content while recognizing the presence of other alloying elements that contribute to its specific properties.

The distinction in nomenclature serves a practical purpose in the industry, ensuring clear communication about material specifications and performance expectations. When professionals in the oil and gas sector refer to API 5L Grade B, they immediately understand the material's characteristics and suitability for pipeline applications.

About Longma Group

In conclusion, while API 5L Grade B does contain carbon as a primary element, it is not typically referred to as "carbon steel" due to its specific composition, manufacturing process, and intended application in the oil and gas industry. The API 5L designation provides a more precise description of the material's properties and performance expectations.

Understanding these distinctions is crucial for professionals working with pipeline materials, as it ensures the selection of appropriate materials for critical applications. The specific requirements of API 5L Grade B, including its chemical composition, mechanical properties, and quality control standards, make it a reliable choice for oil and gas pipelines where safety and durability are paramount.

For those in need of high-quality API 5L welded pipes, Longma Group stands as a leading manufacturer with a proven track record. Specializing in various grades, including API 5L Grade B, X42, X46, X52, X56, X60, X65, X70, and X80, Longma Group offers a range of welding types such as ERW, LSAW, DSAW, and SSAW. With outer diameters from 3" to 80" and thicknesses from SCH10 to SCH160, they can meet diverse project requirements. Backed by API 5L, ISO, and QMS certifications, Longma Group ensures top-quality products with delivery times as fast as 7 days. For expert guidance and superior API 5L pipes, contact Longma Group today at info@longma-group.com. Their commitment to excellence in both products and services makes them an ideal partner for your pipeline projects.