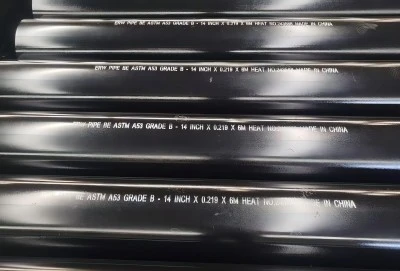

ERW black pipe is indeed commonly coated with a black finish. This protective layer serves multiple purposes in industrial applications. The black coating on ERW (Electric Resistance Welded) pipes is typically applied through a process called black oxide treatment or blackening. This coating enhances the pipe's resistance to corrosion, improves its aesthetic appearance, and provides additional protection against environmental factors. While black coating is prevalent, it's essential to note that ERW pipes are available in various coating options to suit different project requirements.

|

|

|

ERW Pipe Coating Options

While ERW black pipe is a popular choice, there are several other coating options available to meet diverse industry needs. Understanding these alternatives can help project managers and engineers make informed decisions based on their specific requirements.

Galvanized ERW Pipes: Zinc-Coated Protection

Galvanization is a widely used coating method for ERW pipes, offering excellent corrosion resistance. In this process, the pipe is coated with a layer of zinc, which acts as a sacrificial anode. This means the zinc corrodes before the underlying steel, significantly extending the pipe's lifespan. Galvanized ERW pipes are particularly useful in environments where moisture exposure is a concern, such as outdoor installations or underground piping systems.

Epoxy-Coated ERW Pipes for Enhanced Durability

Epoxy coating provides superior protection against chemical corrosion and abrasion. This makes epoxy-coated ERW pipes ideal for use in harsh industrial environments or for transporting corrosive materials. The epoxy layer creates a barrier that prevents direct contact between the pipe's surface and potentially damaging substances, ensuring long-term reliability and reduced maintenance needs.

PE-Coated ERW Pipes for Corrosion Resistance

Polyethylene (PE) coating offers exceptional resistance to both chemical and electrochemical corrosion. PE-coated ERW pipes are often used in underground applications, such as water supply systems or gas distribution networks. The PE layer provides a smooth, low-friction surface that enhances flow efficiency and reduces the risk of bacterial growth, making it an excellent choice for potable water transportation.

The Purpose of Black Coating on ERW Pipes

Black coating on ERW pipes serves several crucial functions in industrial applications. Understanding these benefits can help project managers and engineers appreciate why black-coated pipes are often the preferred choice in many scenarios.

Corrosion Protection: Black Coating's Primary Function

The primary purpose of ERW black pipes is to provide a barrier against corrosion. The coating acts as a shield, preventing moisture and oxygen from directly contacting the steel surface. This protection is particularly important in environments where pipes are exposed to humidity, salt air, or corrosive chemicals. By inhibiting the corrosion process, black coating significantly extends the lifespan of ERW pipes, reducing the need for frequent replacements and minimizing maintenance costs.

Heat Resistance: Black Coating's Added Benefit

Another advantage of ERW black pipes is their heat-resistant properties. The coating can withstand higher temperatures compared to bare steel, making it suitable for applications involving hot fluids or gases. This heat resistance not only protects the pipe itself but also helps maintain the temperature of the materials being transported, which can be crucial in certain industrial processes.

Cost-Effective Solution for Industrial Applications

Black coating offers a cost-effective solution for many industrial applications. Compared to more specialized coatings, ERW black pipes strike a balance between performance and affordability. The coating process is relatively simple and can be applied efficiently, keeping production costs down. Additionally, the extended lifespan and reduced maintenance requirements of black-coated pipes contribute to their overall cost-effectiveness in the long run.

Uncoated vs. Black-Coated ERW Pipes: Pros and Cons

When choosing between uncoated and ERW black pipes, it's important to consider the specific requirements of your project. Both options have their advantages and drawbacks, and understanding these can help in making an informed decision.

Durability Comparison: Bare Steel vs. Black Coating

Bare steel ERW pipes offer the advantage of being less expensive initially. However, they are more susceptible to corrosion and environmental damage. Black-coated ERW pipes, on the other hand, provide enhanced durability due to their protective layer. This coating significantly slows down the corrosion process, potentially extending the pipe's lifespan by several years. In environments with high humidity or exposure to corrosive elements, black-coated pipes clearly outperform their uncoated counterparts in terms of longevity.

Cost Analysis: Initial Investment vs. Long-Term Savings

While uncoated ERW pipes may have a lower upfront cost, the long-term financial implications often favor black-coated pipes. The initial savings on uncoated pipes can be quickly offset by increased maintenance costs, more frequent replacements, and potential system downtime. Black-coated pipes, despite their higher initial price, often prove more economical over time due to their extended service life and reduced maintenance requirements. This is particularly true in industries where pipe failure can lead to significant production losses or safety hazards.

Application Suitability: Choosing the Right ERW Pipe

The choice between uncoated and black-coated ERW pipes largely depends on the specific application. Uncoated pipes might be suitable for temporary installations or in controlled environments where corrosion is not a significant concern. However, for most industrial applications, especially those involving outdoor exposure or corrosive materials, black-coated ERW pipes are the preferred choice. They offer better protection against rust, improved resistance to chemical reactions, and greater overall reliability in challenging conditions.

ERW black pipe offers a robust solution for various industrial applications, balancing durability with cost-effectiveness. The black coating provides essential protection against corrosion and heat, extending the pipe's lifespan and reducing maintenance needs. While alternative coatings like galvanization, epoxy, and PE offer specialized benefits, black-coated ERW pipes remain a versatile choice for many projects. When selecting between uncoated and black-coated options, consider factors such as environmental conditions, long-term costs, and specific application requirements to make the best decision for your project's success.

ERW Black Pipes Manufacturer

Hebei Longma Group is a leading manufacturer of high-quality ERW black pipes. Our advanced production equipment, imported from Germany and complemented by four independently developed production lines, ensures top-notch quality. With a professional team of over 300 employees, including 60+ technical experts, we guarantee precision and innovation in every product. Our comprehensive testing facilities, including ultrasonic flaw detectors and industrial X-ray equipment, ensure strict quality control. We pride ourselves on fast delivery. Backed by complete certifications including API 5L and ISO 9001, we offer competitive pricing thanks to our integrated production model and stable raw material partnerships. For reliable black pipes that meet your project's demands, contact us at info@longma-group.com.