Surface anti-corrosion treatment for steel pipes is a crucial process in ensuring the longevity and reliability of pipeline infrastructure. Anti-corrosion steel pipes play a vital role in various industries, including oil and gas transportation, water supply systems, and offshore platform construction. These specialized pipes are designed to withstand harsh environments, chemical exposure, and extreme temperatures, making them essential for projects in the Middle East, Australia, and Southeast Asia. By implementing advanced coating technologies and innovative application methods, engineers and project managers can significantly extend the lifespan of their pipeline systems while reducing maintenance costs and environmental impact.

|

|

|

Innovative Surface Treatment Technologies

Advanced PE Coating: LONGMA GROUP's Specialty

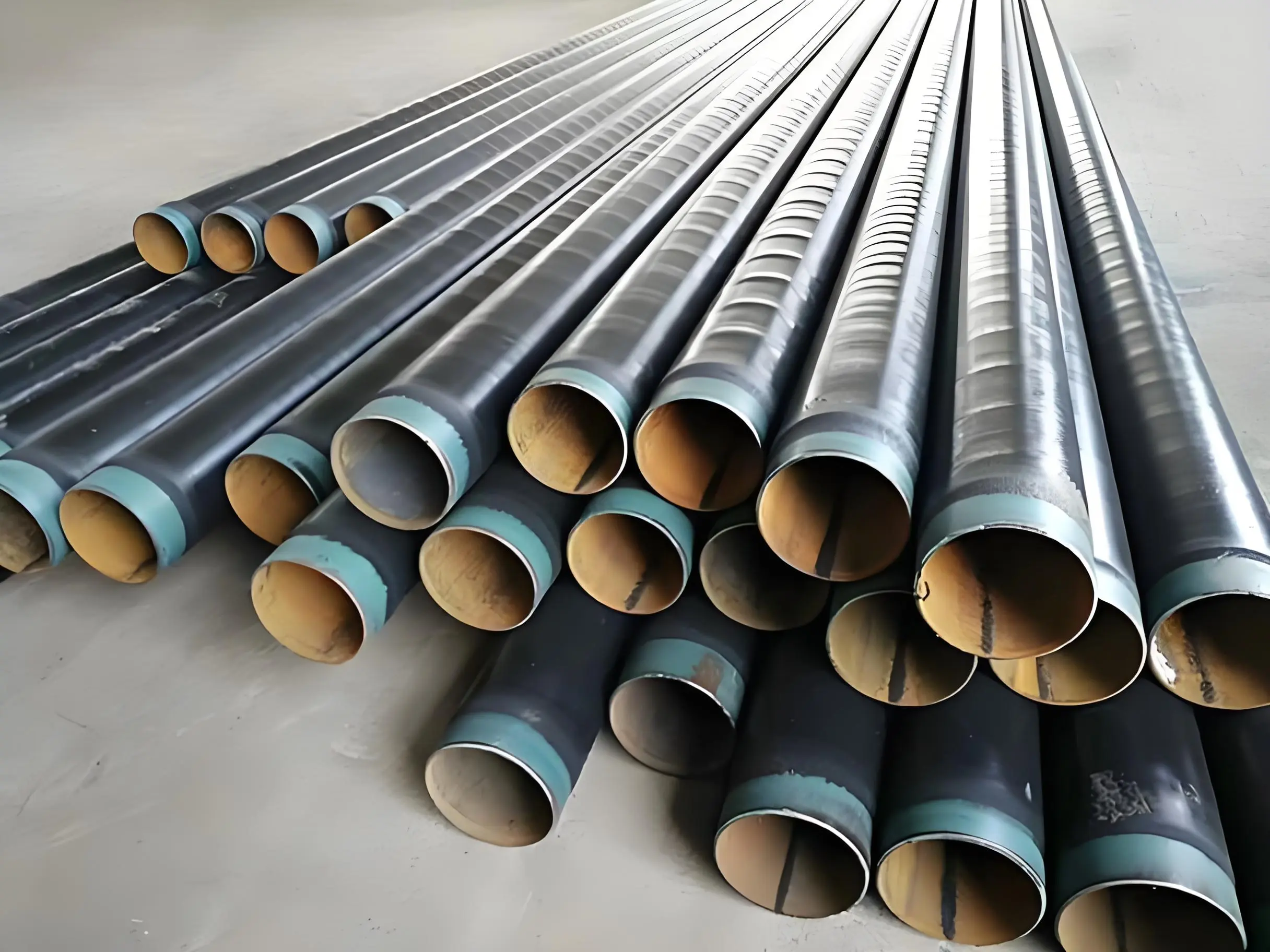

LONGMA GROUP has pioneered the use of advanced polyethylene (PE) coating for steel pipes, setting new standards in the industry. This cutting-edge technology provides superior protection against corrosion, abrasion, and chemical attack. The PE coating process involves multiple layers, each serving a specific purpose in safeguarding the pipe's integrity. The inner layer ensures strong adhesion to the steel surface, while the outer layer offers excellent resistance to environmental factors. This innovative approach has proven particularly effective in challenging environments, such as offshore installations and underground pipelines in areas with high soil acidity.

Nanotechnology in Anti-Corrosion Coatings

The integration of nanotechnology in anti-corrosion coatings represents a significant leap forward in surface treatment for steel pipes. These advanced coatings incorporate nanoparticles that fill microscopic gaps and imperfections in the pipe's surface, creating an ultra-smooth and highly resistant barrier. Nanocomposite coatings have demonstrated remarkable performance in preventing corrosion initiation and propagation, even in the most aggressive environments. For project managers and engineers working on large-scale infrastructure projects, the adoption of nanotechnology-based coatings can lead to substantial cost savings over the lifetime of the pipeline system.

Ceramic-Based Protective Layers for Extreme Conditions

In scenarios where steel pipes are exposed to extreme temperatures or highly corrosive substances, ceramic-based protective layers offer unparalleled protection. These advanced coatings combine the durability of ceramics with the flexibility needed for pipeline applications. The result is a surface treatment that can withstand temperatures exceeding 1000°C and resist attack from a wide range of chemicals. For industries such as petrochemical processing and geothermal energy production, ceramic-based coatings provide a reliable solution for extending the service life of critical pipeline infrastructure.

Environmental Impact of Anti-Corrosion Treatments

Eco-Friendly Alternatives to Traditional CoatingsThe development of eco-friendly alternatives to traditional anti-corrosion coatings marks a significant shift towards sustainability in the pipeline industry. Water-based epoxy coatings and solvent-free polyurethane systems have emerged as environmentally responsible options that maintain high performance standards. These innovative coatings reduce volatile organic compound (VOC) emissions during application and curing, minimizing the environmental footprint of pipeline projects. For plant equipment managers and procurement specialists, selecting these eco-friendly coatings aligns with corporate sustainability goals without compromising on protection quality.

Reducing Carbon Footprint in Steel Pipe Manufacturing

The steel pipe manufacturing industry is taking proactive steps to reduce its carbon footprint, with anti-corrosion treatments playing a key role in this effort. Advanced coating technologies now require less energy to apply and cure, significantly lowering the overall energy consumption of the manufacturing process. Additionally, the extended lifespan of properly treated pipes means fewer replacements and less frequent maintenance, further reducing the long-term environmental impact. By choosing anti-corrosion steel pipes with these advanced treatments, project managers contribute to more sustainable infrastructure development.

Recyclability of Anti-Corrosion Treated Steel Pipes

Addressing the end-of-life considerations for anti-corrosion treated steel pipes is crucial for achieving a circular economy in the construction and industrial sectors. Modern coating technologies are designed with recyclability in mind, allowing for easier separation of the protective layers from the base metal during the recycling process. This advancement ensures that the valuable steel can be reclaimed and repurposed, minimizing waste and conserving resources. For large-scale engineering contractors, specifying recyclable anti-corrosion treatments aligns with increasingly stringent environmental regulations and corporate sustainability targets.

Application Methods: Pros and Cons

Spray Coating vs. Dip Coating: Efficiency ComparisonThe choice between spray coating and dip coating methods for applying anti-corrosion treatments to steel pipes depends on various factors, including pipe size, production volume, and specific project requirements. Spray coating offers precise control over coating thickness and is well-suited for large diameter pipes and custom applications. It allows for quick color changes and can be more cost-effective for smaller production runs. On the other hand, dip coating provides excellent coverage, including hard-to-reach areas, and is typically more efficient for high-volume production of smaller diameter pipes. Understanding the pros and cons of each method enables project procurement managers to make informed decisions that balance quality, cost, and production timelines.

Electrophoretic Deposition for Complex Pipe Geometries

Electrophoretic deposition has emerged as a game-changing application method for anti-corrosion coatings on steel pipes with complex geometries. This innovative technique uses an electric current to deposit coating particles uniformly across the pipe's surface, ensuring complete coverage even in intricate shapes and tight spaces. The result is a highly consistent and defect-free protective layer that significantly enhances corrosion resistance. For pipeline engineers working on projects with non-standard pipe configurations, electrophoretic deposition offers a reliable solution that combines efficiency with superior protection.

Thermal Spraying: Durability in Harsh Environments

Thermal spraying techniques have gained popularity for applying anti-corrosion coatings in particularly harsh environments, such as offshore platforms and chemical processing plants. This method involves spraying molten or semi-molten materials onto the pipe surface, creating a strong, adherent coating that can withstand extreme temperatures and chemical exposure. Thermal sprayed coatings offer exceptional durability and can be customized to meet specific environmental challenges. While initially more costly than some other application methods, the long-term performance benefits make thermal spraying an attractive option for critical infrastructure projects where reliability is paramount.

The evolution of surface anti-corrosion treatments for steel pipes has revolutionized the pipeline industry, offering unprecedented protection and longevity. From advanced PE coatings to nanotechnology-enhanced solutions, these innovations address the diverse needs of global infrastructure projects. As environmental considerations become increasingly important, the industry's shift towards eco-friendly coatings and sustainable manufacturing processes demonstrates a commitment to responsible development. By carefully selecting the appropriate anti-corrosion treatment and application method, project managers and engineers can ensure the long-term success and sustainability of their pipeline systems, contributing to more resilient and efficient infrastructure worldwide.

Anti-Corrosion Steel Pipe For Sale

Hebei Longma Group stands at the forefront of steel pipe manufacturing, offering state-of-the-art solutions for your pipeline needs. Our advanced production equipment, imported from Germany and enhanced with our own innovations, ensures top-quality anti-corrosion steel pipes. With a professional team of over 300 employees, including 60+ technical experts, we guarantee expertise in every aspect of production. Our comprehensive testing facilities, featuring ultrasonic flaw detectors and industrial X-ray systems, ensure the highest standards of quality control. We pride ourselves on fast delivery, with standard thickness pipes ready in as little as 7 days. Backed by complete certifications including API 5L, ISO 9001, and ISO 14001, our products meet international standards. Thanks to our integrated production model and strong supplier relationships, we offer competitive pricing without compromising on quality. For inquiries about our steel pipes, available in outer diameters from 60.3-1422mm and wall thicknesses of 6.02-50.8mm, contact us at info@longma-group.com.