ASTM A53 Gr B Pipes are widely used in various industries, including oil and gas, water supply systems, and structural applications. These pipes come in two main types: seamless and welded. The key difference lies in their manufacturing processes, which significantly impact their performance characteristics. Seamless pipes are formed from a solid cylindrical billet without welding, while welded pipes are created by rolling flat steel and joining the edges. This distinction affects strength, pressure ratings, and corrosion resistance, making the choice between seamless and welded A53 Gr B pipes crucial for project success.

|

|

|

Manufacturing Process: Impact on Pipe Performance

Seamless A53 Gr B: Hot Rolling vs. Cold Drawing

Seamless ASTM A53 Gr B pipes are manufactured through two primary methods: hot rolling and cold drawing. Hot rolling involves heating a steel billet to high temperatures and then piercing it to create a hollow pipe. This process results in pipes with uniform wall thickness and excellent mechanical properties. Cold drawing, on the other hand, involves pulling a hollow tube through a series of dies to reduce its diameter and wall thickness. This method produces pipes with tighter tolerances and smoother surfaces.

Welded A53 Gr B: ERW and LSAW Techniques Compared

Welded ASTM A53 Gr B pipes are typically produced using either Electric Resistance Welding (ERW) or Longitudinal Submerged Arc Welding (LSAW). ERW pipes are made by rolling flat steel into a cylindrical shape and welding the edges using high-frequency electrical current. This method is cost-effective and suitable for smaller diameter pipes. LSAW pipes, used for larger diameters, involve welding pre-formed plates using a submerged arc welding process, resulting in a strong, high-quality weld seam.

Quality Control: Ensuring A53 Gr B Pipe Integrity

Rigorous quality control measures are essential for both seamless and welded ASTM A53 Gr B Pipes. Non-destructive testing techniques, such as ultrasonic inspection and radiographic testing, are employed to detect any flaws or inconsistencies in the pipe wall. Additionally, hydrostatic pressure tests are conducted to verify the pipe's ability to withstand specified pressures. These quality control procedures are crucial in maintaining the integrity and reliability of ASTM A53 Gr B pipes, regardless of their manufacturing method.

Strength Variations: Seamless vs. Welded A53 Gr B

Pressure Ratings: A53 Gr B Seamless vs. Welded PipesThe pressure ratings of ASTM A53 Gr B pipes differ between seamless and welded varieties. Seamless pipes generally offer higher pressure ratings due to their uniform structure and absence of weld seams. This makes them ideal for high-pressure applications in oil and gas transportation. Welded pipes, while still capable of handling significant pressures, may have slightly lower ratings due to the presence of the weld seam. However, advancements in welding technology have narrowed this gap, making welded pipes suitable for many high-pressure applications as well.

Corrosion Resistance in A53 Gr B Pipe Types

Corrosion resistance is a critical factor in pipe selection, especially for projects in corrosive environments. Seamless ASTM A53 Gr B pipes often exhibit superior corrosion resistance due to their homogeneous structure. The absence of a weld seam eliminates a potential weak point for corrosion initiation. Welded pipes, while still corrosion-resistant, may require additional protective measures, such as hot-dip galvanizing, to enhance their durability in harsh conditions. The choice between seamless and welded pipes for corrosion resistance often depends on the specific environmental factors of the project.

Fatigue Performance of A53 Gr B Seamless and Welded Pipes

Fatigue performance is another area where seamless and welded ASTM A53 Gr B Pipes may differ. Seamless pipes typically demonstrate better fatigue resistance due to their uniform microstructure. This makes them particularly suitable for applications involving cyclic loading or vibrations. Welded pipes, while still capable of withstanding fatigue, may require additional considerations in design and installation to ensure long-term reliability under cyclic stress conditions. The fatigue performance of both types can be further enhanced through proper heat treatment and quality control during manufacturing.

Choosing the Right Pipe: Application-Specific Considerations

A53 Gr B in Oil and Gas: Seamless or Welded?In the oil and gas industry, the choice between seamless and welded ASTM A53 Gr B pipes depends on various factors. Seamless pipes are often preferred for high-pressure, deep-well applications due to their superior strength and uniform wall thickness. They excel in environments where safety and reliability are paramount. Welded pipes, however, find extensive use in gathering lines and less demanding sections of pipelines. Their cost-effectiveness and availability in larger diameters make them attractive for many oil and gas projects. The decision ultimately hinges on specific project requirements, operating conditions, and budget constraints.

Water Supply Systems: A53 Gr B Pipe Selection Guide

For water supply systems, both seamless and welded ASTM A53 Gr B pipes have their place. Seamless pipes are often chosen for critical sections of the system, particularly where high pressures or challenging environmental conditions are present. Their resistance to corrosion and ability to withstand pressure fluctuations make them ideal for main transmission lines. Welded pipes, being more economical, are commonly used in distribution networks and less critical sections. The selection process should consider factors such as water quality, system pressure, soil conditions, and long-term maintenance requirements.

Cost-Efficiency: A53 Gr B Seamless vs. Welded for Projects

Cost-efficiency is a crucial factor in pipe selection for large-scale projects. Welded ASTM A53 Gr B Pipes generally offer a more economical solution, especially for projects requiring large quantities of pipe. Their manufacturing process is more efficient, resulting in lower production costs. Seamless pipes, while more expensive, may prove cost-effective in the long run for applications where their superior properties can extend the lifespan of the system or reduce maintenance needs. Project managers must weigh the initial investment against long-term performance and maintenance costs when making their selection.

The choice between seamless and welded ASTM A53 Gr B pipes is not a one-size-fits-all decision. Each type has its strengths and optimal applications. Seamless pipes excel in high-pressure, corrosive environments and critical systems where reliability is paramount. Welded pipes offer cost-effectiveness and are suitable for a wide range of standard applications. The key to successful project outcomes lies in understanding the specific requirements of each application and making an informed decision based on factors such as pressure ratings, corrosion resistance, fatigue performance, and overall cost-efficiency. By carefully considering these aspects, engineers and project managers can ensure the selection of the most appropriate ASTM A53 Gr B pipe for their specific needs.

ASTM A53 Gr B Pipes Supplier

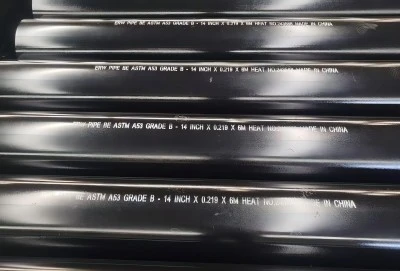

When seeking high-quality A53 Gr B pipes for your project, Hebei Longma Group stands out as a premier manufacturer and supplier. Our advanced production equipment, imported from Germany and complemented by four independently developed machines, ensures top-notch pipe quality. With a professional team of over 300 employees, including 60+ technical experts and an independent research team, we guarantee expertise in every aspect of pipe production. Our comprehensive testing facilities, featuring ultrasonic flaw detectors and industrial X-ray equipment, maintain rigorous quality control. We pride ourselves on fast delivery, with standard thickness pipes ready in as little as 7 days. Our complete certification, including API 5L and ISO 9001, assures compliance with international standards. Thanks to our integrated production model and long-term partnerships with raw material suppliers, we offer competitive pricing without compromising on quality. For all your ASTM A53 Gr B pipe needs, contact us at info@longma-group.com.