API 5L PSL1 steel pipes represent a crucial component in various industrial applications, manufactured according to the stringent specifications set by the American Petroleum Institute (API). These pipes have gained widespread recognition for their exceptional mechanical properties, durability, and reliability across different sectors. Understanding their diverse applications and characteristics is essential for industry professionals and decision-makers involved in infrastructure development and industrial operations.

|

|

|

Oil And Gas Industry

In the oil and gas industry, API 5L PSL1 steel pipes serve as the cornerstone of transportation infrastructure, playing a vital role in ensuring safe and efficient hydrocarbon movement. These pipes are engineered to handle operating pressures up to 2,800 psi, depending on the specific grade and wall thickness selected. The robust design and construction make them ideal for various applications within the sector. In upstream operations, these pipes are extensively utilized in gathering lines and flow lines, connecting wellheads to processing facilities. Their high pressure-bearing capacity and resistance to various forms of corrosion make them particularly suitable for handling raw hydrocarbon products. The pipes' excellent weldability ensures reliable field joints, crucial for maintaining system integrity in challenging environments.

For midstream operations, API 5L PSL1 pipes form the backbone of transmission pipeline networks, capable of spanning thousands of miles while maintaining structural integrity. The pipes' chemical composition and heat treatment processes ensure optimal strength-to-weight ratios, facilitating easier installation while maintaining necessary durability. Their resistance to both internal and external corrosion is enhanced through various coating technologies, extending operational lifespan and reducing maintenance requirements. The downstream sector benefits from these pipes in refineries and distribution networks, where their ability to handle various refined products at different temperatures and pressures proves invaluable. The standardized manufacturing process ensures consistent quality across different production batches, critical for maintaining safety standards in hydrocarbon transportation.

Water Transportation

The water transportation sector extensively employs API 5L PSL1 steel pipes due to their versatility and reliability. In municipal water supply systems, these pipes form critical components of the distribution network, handling varying pressure requirements and environmental conditions. Their application extends from main transmission lines to smaller distribution networks, providing consistent water supply to urban and rural areas.

Industrial water management systems particularly benefit from these pipes' durability and corrosion resistance. The pipes are utilized in cooling water circuits, process water transportation, and wastewater management systems. Their smooth internal surface, achieved through precise manufacturing processes, minimizes friction losses and enhances flow efficiency, resulting in reduced pumping costs and improved system performance. In irrigation systems, API 5L PSL1 pipes demonstrate exceptional versatility. Their ability to withstand varied soil conditions and external pressures makes them ideal for both surface and subsurface irrigation networks. The pipes' durability in high-pressure applications allows for efficient water distribution across large agricultural areas, contributing to improved irrigation efficiency and water conservation.

Construction And Engineering

The construction and engineering sector leverages API 5L PSL1 steel pipes for numerous applications, capitalizing on their structural integrity and reliability. In building construction, these pipes serve as essential components in foundation systems, particularly in deep foundation applications where high load-bearing capacity is crucial. Their uniform wall thickness and precise dimensional tolerances ensure consistent performance in structural applications.

Bridge construction particularly benefits from these pipes' characteristics. They are employed in pile foundations, supporting structures, and utility conduits. The pipes' high tensile strength and compression resistance make them ideal for handling both static and dynamic loads experienced in bridge structures. Their weldability facilitates proper connection details, ensuring structural continuity and load transfer. In industrial plant construction, API 5L PSL1 pipes find applications in support structures, utility systems, and process piping. Their versatility allows for both temporary and permanent structural applications, while their standardized specifications facilitate integration with other building components. The pipes' durability in various environmental conditions contributes to reduced maintenance requirements and extended service life.

Electricity Heating Power

In the power generation sector, API 5L PSL1 steel pipes play multiple crucial roles. Thermal power plants utilize these pipes extensively in their steam transportation systems, where the pipes' ability to handle high temperatures and pressures is essential. The pipes' thermal resistance and structural stability make them ideal for both main steam lines and auxiliary systems. Hydroelectric power plants employ these pipes in penstock systems, where their pressure-bearing capacity and durability are crucial for efficient water conveyance. The pipes' resistance to water hammer effects and ability to maintain structural integrity under varying pressure conditions make them particularly suitable for such applications.

In district heating systems, API 5L PSL1 pipes serve as primary transportation conduits for hot water or steam. Their thermal insulation properties, when properly coated, help maintain energy efficiency in heating networks. The pipes' resistance to thermal cycling and their long-term reliability make them cost-effective choices for district heating infrastructure. The electrical distribution sector uses these pipes as protective conduits for underground power cables. Their corrosion resistance and structural strength provide reliable protection for electrical infrastructure, while their smooth internal surface facilitates cable installation and maintenance.

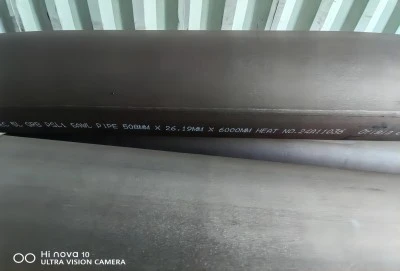

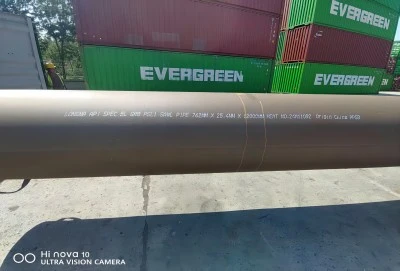

LONGMA GROUP API 5L PSL1

LONGMA GROUP has established itself as a prominent manufacturer of API 5L PSL1 steel pipes, offering a comprehensive range of products that meet various international standards. Their manufacturing capabilities encompass pipes conforming to API 5L, ASTM A53, ASTM A500, ASTM A252, and ASTM A795 specifications, catering to diverse industry requirements. The company implements rigorous quality control measures throughout its manufacturing process, ensuring consistent product quality and compliance with international standards. Their quality assurance program includes comprehensive testing of mechanical properties, chemical composition analysis, and dimensional accuracy verification. Each production batch undergoes thorough inspection and testing to maintain high-quality standards.

LONGMA GROUP's manufacturing facilities utilize advanced technology and automated processes to ensure precise dimensional control and surface finish. Their production capabilities allow for manufacturing pipes in various sizes and specifications, meeting specific customer requirements. The company's commitment to research and development ensures continuous improvement in product quality and manufacturing efficiency.

Their technical support team provides comprehensive assistance in product selection and application guidance, helping customers choose the most suitable products for their specific requirements. The company's global presence and efficient logistics network ensure timely delivery and reliable customer service worldwide. For those seeking a reliable API 5L PSL1 manufacturer, LONGMA GROUP welcomes inquiries at info@longma-group.com. Their technical team can provide detailed specifications and assist in selecting the most appropriate pipe specifications for your project requirements.