API 5L ERW pipe is a crucial component in the oil and gas industry, known for its reliability and performance in pipeline systems. As a leading manufacturer of ERW and LSAW steel pipes, Longma Group is committed to providing high-quality API 5L ERW pipes that meet industry standards. In this comprehensive guide, we'll delve into the key specifications, dimensional ranges, chemical composition requirements, and pressure ratings.

|

|

|

What are the Key Specifications of API 5L ERW Pipe?

API 5L ERW pipe, also known as Electric Resistance Welded pipe, is manufactured according to the American Petroleum Institute (API) 5L specification. This standard outlines the requirements for seamless and welded steel line pipes used in pipeline transportation systems in the petroleum and natural gas industries. The key specifications include:

- Material Grade: API 5L ERW pipes are available in various grades, including A25, A, B, X42, X46, X52, X56, X60, X65, X70, and X80. Each grade has specific mechanical properties and chemical composition requirements.

- Product Specification Levels: API 5L pipes are classified into two product specification levels (PSL): PSL1 and PSL2. PSL2 has more stringent requirements for chemical composition, mechanical properties, and non-destructive examination.

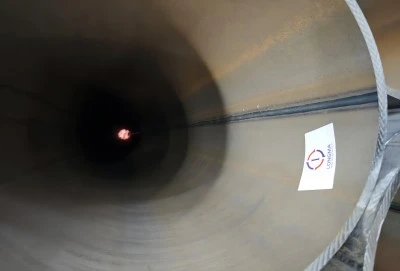

- Manufacturing Process: ERW pipes are produced by forming steel coils or plates into a cylindrical shape and welding the longitudinal seam using electric resistance welding technology.

- Heat Treatment: Depending on the grade and requirements, API 5L ERW pipes may undergo heat treatment processes such as normalizing, quenching, and tempering to achieve the desired mechanical properties.

- Surface Finish: API 5L pipes can be supplied with various surface finishes, including as-welded, pickled and oiled, or with external/internal coatings for corrosion protection.

These specifications ensure that API 5L ERW pipes meet the stringent requirements of the oil and gas industry, providing reliable performance in demanding applications.

What are the Dimensional Ranges of API 5L ERW Pipe?

API 5L ERW pipes are available in a wide range of dimensions to suit various pipeline applications. The dimensional ranges include:

- Outside Diameter (OD): API 5L ERW pipes typically range from 1/2 inch (12.7 mm) to 24 inches (609.6 mm). However, the most common sizes are between 2 inches (50.8 mm) and 20 inches (508 mm).

- Wall Thickness: The wall thickness varies depending on the required pressure rating and application. It can range from 0.109 inches (2.77 mm) to 0.750 inches (19.05 mm) or more.

- Length: Standard lengths are typically 12 meters (39.4 feet) or 6 meters (19.7 feet). However, custom lengths can be manufactured based on specific project requirements.

- End Finish: API 5L ERW pipes can be supplied with plain ends, beveled ends for welding, or threaded ends for specific connections.

It's important to note that the availability of specific dimensions may vary depending on the manufacturer and the pipe grade. At Longma Group, we offer a comprehensive range of API 5L ERW pipe dimensions to meet diverse project needs.

What are the Chemical Composition Requirements for API 5L ERW Pipe?

The chemical composition of API 5L ERW pipe is crucial in determining its mechanical properties and performance. The API 5L specification outlines specific requirements for the chemical composition of different grades. Here are some key elements and their typical ranges:

- Carbon (C): 0.05% - 0.28% (depending on the grade)

- Manganese (Mn): 0.60% - 1.75% (depending on the grade)

- Phosphorus (P): 0.030% max (PSL1), 0.025% max (PSL2)

- Sulfur (S): 0.030% max (PSL1), 0.015% max (PSL2)

- Silicon (Si): 0.10% - 0.45% (depending on the grade)

- Vanadium (V), Niobium (Nb), and Titanium (T): These elements may be added to enhance mechanical properties, with specific limits defined for each grade.

For higher-grade API 5L ERW pipes, additional alloying elements such as Chromium (Cr), Nickel (Ni), and Molybdenum (Mo) may be included to improve strength and corrosion resistance. The exact chemical composition requirements vary depending on the pipe grade and product specification level (PSL1 or PSL2).

It's worth noting that the carbon equivalent (CE) is an important factor in determining the weldability of the pipe. The API 5L specification provides formulas for calculating CE based on the chemical composition, with maximum limits specified for different grades.

What are the Pressure Ratings and Wall Thickness Specifications?

The pressure ratings and wall thickness specifications of API 5L ERW pipe are critical factors in determining its suitability for specific pipeline applications. These specifications are closely related and depend on various factors, including:

- Pipe Grade: Higher-grade pipes (e.g., X65, X70) generally have higher pressure ratings due to their increased yield strength.

- Outside Diameter: Larger diameter pipes typically require thicker walls to withstand the same internal pressure as smaller diameter pipes.

- Design Factor: This safety factor is applied to account for various uncertainties and to ensure a margin of safety in pipeline design.

- Service Conditions: The operating temperature, pressure fluctuations, and external loads influence the required wall thickness and pressure rating.

The wall thickness of API 5L ERW pipe is typically specified using one of two methods:

- Standard Wall Thickness: Pipes are manufactured according to standardized wall thickness schedules (e.g., SCH 40, SCH 80) based on the nominal pipe size.

- Custom Wall Thickness: Pipes can be manufactured with specific wall thicknesses calculated based on the design pressure, pipe diameter, and material properties.

The pressure rating of API 5L ERW pipe is determined using the following formula:

P = (2 * S * t) / (D * F)

Where: P = Design pressure S = Specified minimum yield strength t = Nominal wall thickness D = Nominal outside diameter F = Design factor (typically 0.72 for oil and gas pipelines)

It's important to note that the actual pressure rating may be lower than the calculated value due to additional factors such as temperature derating, joint efficiency, and corrosion allowance.

Contact Longma Group

At Longma Group, we specialize in manufacturing high-quality API 5L ERW pipes that meet and exceed industry standards. Our comprehensive range of grades, sizes, and wall thicknesses ensures that we can provide the perfect solution for your pipeline project. With our state-of-the-art manufacturing facilities and stringent quality control processes, we guarantee the reliability and performance of our ERW pipes.

If you're looking for premium API 5L pipes for your next project, don't hesitate to reach out to our team of experts. We're here to answer your questions, provide detailed product information, and offer competitive quotes. Contact us today at info@longma-group.com and experience the Longma Group difference in pipe procurement. Let's work together to ensure the success of your pipeline project!