Porosity in carbon steel pipe welding is a common issue that can significantly impact the integrity and performance of welded joints. This defect occurs when gas bubbles become trapped within the weld metal during solidification, creating small voids or pores. In carbon pipe welding, porosity can be caused by various factors, including moisture contamination, improper shielding gas flow, and surface contaminants. Understanding these causes is crucial for pipeline engineers, project managers, and welding professionals working in oil and gas transportation, water supply systems, and industrial manufacturing sectors.

|

|

|

Common sources of welding porosity

Moisture contamination in carbon steel pipe welds

Moisture is one of the primary culprits behind porosity in carbon steel pipe welding. When moisture is present in the welding environment or on the pipe surface, it can break down into hydrogen and oxygen during the welding process. The hydrogen then becomes trapped in the molten weld pool, forming bubbles as the metal solidifies. This phenomenon is particularly problematic in high-humidity environments or when working with pipes that have been exposed to wet conditions.

To combat moisture-related porosity, welders must ensure that carbon steel pipes are thoroughly dried before welding. This may involve preheating the pipes to drive out any residual moisture or using specialized drying techniques. Additionally, proper storage of welding consumables, such as electrodes and filler metals, is essential to prevent moisture absorption.

Improper shielding gas flow rates and coverage

Shielding gas plays a crucial role in protecting the weld pool from atmospheric contamination during the welding process. When the shielding gas flow rate is too low or the coverage is inadequate, atmospheric gases can enter the weld pool, leading to porosity. This issue is particularly relevant in outdoor welding environments where wind can disrupt the shielding gas envelope.

Welders must carefully adjust and monitor shielding gas flow rates to ensure optimal coverage. For carbon steel pipe welding, a common shielding gas mixture is 75% argon and 25% carbon dioxide, which provides good arc stability and weld penetration. Proper selection of gas nozzle size and maintaining the correct distance between the nozzle and the workpiece are also critical factors in preventing porosity.

Contaminants on pipe surfaces before welding

Surface contaminants on carbon steel pipes can significantly contribute to weld porosity. These contaminants may include oil, grease, rust, paint, or mill scale. When exposed to high welding temperatures, these substances can vaporize and introduce gas into the weld pool, resulting in porosity.

Thorough cleaning of pipe surfaces prior to welding is essential. This typically involves mechanical cleaning methods such as wire brushing, grinding, or sandblasting, followed by chemical cleaning with appropriate solvents. For large-scale projects, automated cleaning systems may be employed to ensure consistent surface preparation across multiple pipe sections.

Preventing porosity: Best practices

Proper storage and handling of carbon steel pipesEffective storage and handling practices are crucial in preventing porosity in carbon steel pipe welding. Pipes should be stored in a clean, dry environment, preferably indoors or under protective coverings to shield them from moisture and contaminants. When transporting pipes to the welding site, care must be taken to prevent damage to the pipe ends and surfaces, which could create areas prone to contamination.

Implementing a proper inventory management system ensures that pipes are used on a first-in, first-out basis, reducing the likelihood of prolonged exposure to potentially harmful environmental conditions. For projects in humid climates, such as those in Southeast Asia or the Middle East, additional precautions may be necessary, such as using dehumidifiers in storage areas or applying protective coatings to pipe surfaces.

Optimizing welding parameters for ERW and LSAW pipes

Electric Resistance Welded (ERW) and Longitudinal Submerged Arc Welded (LSAW) pipes are common types of carbon steel pipes used in various industries. Optimizing welding parameters for these pipe types is essential in preventing porosity and ensuring high-quality welds.

For ERW pipes, key parameters to consider include welding current, squeeze time, and forge pressure. Proper control of these variables helps ensure complete fusion and minimal porosity. In LSAW welding, factors such as welding current, arc voltage, travel speed, and flux composition must be carefully adjusted to achieve optimal results. Welding professionals should consult manufacturer guidelines and industry standards, such as API 5L, to determine the appropriate parameters for specific pipe grades and dimensions.

Pre-weld cleaning techniques for steel pipe surfaces

Effective pre-weld cleaning is critical in preventing porosity caused by surface contaminants. For carbon steel pipes, a combination of mechanical and chemical cleaning methods is often employed. Mechanical cleaning may involve wire brushing, grinding, or abrasive blasting to remove rust, mill scale, and other surface impurities.

Chemical cleaning typically follows mechanical methods to remove any remaining contaminants. Solvents such as acetone or alcohol are commonly used to degrease surfaces. In some cases, acid pickling may be necessary for heavily oxidized surfaces. It's important to note that any chemicals used in the cleaning process must be completely removed before welding to prevent introducing new contaminants.

Detecting and repairing porous welds

Non-destructive testing methods for weld porosityDetecting porosity in carbon steel pipe welds is crucial for ensuring the integrity and safety of piping systems. Non-destructive testing (NDT) methods are widely used in the industry to identify and assess weld defects without damaging the pipe. Common NDT techniques for detecting porosity include:

1. Radiographic Testing (RT): This method uses X-rays or gamma rays to create an image of the weld interior, revealing pores as dark spots on the radiograph. RT is particularly effective for detecting subsurface porosity.

2. Ultrasonic Testing (UT): High-frequency sound waves are used to detect discontinuities within the weld. Advanced UT techniques, such as phased array ultrasonic testing (PAUT), can provide detailed imaging of weld defects, including porosity.

3. Visual Inspection: While limited to surface defects, trained inspectors can often detect visible porosity through careful examination of the weld surface.

Repair procedures for porous carbon steel pipe welds

When porosity is detected in carbon steel pipe welds, appropriate repair procedures must be implemented to restore the weld's integrity. The repair process typically involves the following steps:

1. Defect Removal: The porous area is removed using grinding or gouging techniques. The extent of removal is determined by the size and distribution of the porosity.

2. Surface Preparation: The exposed area is cleaned and prepared for rewelding, following the same pre-weld cleaning procedures used for initial welding.

3. Rewelding: The removed section is rewelded using the appropriate welding process and parameters. Special attention is given to controlling heat input and maintaining proper shielding gas coverage.

4. Post-Weld Heat Treatment: Depending on the pipe material and service conditions, post-weld heat treatment may be necessary to relieve residual stresses and improve the weld's mechanical properties.

Quality control measures in steel pipe manufacturing

Implementing robust quality control measures during the manufacturing process is essential for minimizing the occurrence of porosity in carbon steel pipe welds. Key aspects of quality control include:

1. Material Verification: Ensuring that the chemical composition and mechanical properties of the steel meet the required specifications.

2. Process Control: Monitoring and controlling critical parameters such as welding current, voltage, and travel speed throughout the manufacturing process.

3. In-Process Inspection: Conducting regular inspections during production to identify and address potential issues before they lead to defects.

4. Final Inspection: Performing comprehensive NDT on finished pipes to verify weld quality and detect any remaining defects.

Porosity in carbon steel pipe welding poses significant challenges for engineers and welding professionals in various industries. By understanding the common causes of porosity and implementing best practices in pipe handling, welding parameter optimization, and surface preparation, the risk of this defect can be significantly reduced. Regular quality control measures and the use of advanced non-destructive testing methods further ensure the integrity of welded joints in critical applications such as oil and gas transportation and water supply systems. As the demand for high-quality carbon steel pipes continues to grow in global markets, particularly in the Middle East, Australia, and Southeast Asia, maintaining expertise in porosity prevention and remediation remains crucial for project success and long-term infrastructure reliability.

Where to Buy Carbon Steel Pipes?

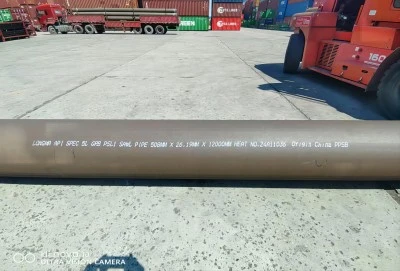

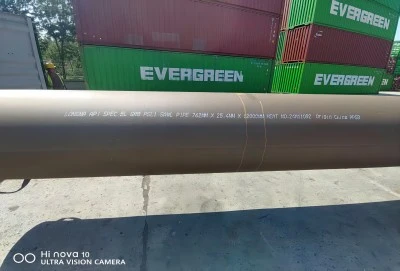

When it comes to sourcing high-quality carbon pipes for your projects, Hebei Longma Group stands out as a reliable and experienced manufacturer. With advanced production equipment imported from Germany and independently developed technologies, we ensure superior product quality. Our professional team of over 300 employees, including more than 60 technical personnel, brings expertise to every stage of production. We're equipped with comprehensive testing facilities, including online ultrasonic automatic flaw detectors and industrial X-ray television, ensuring rigorous quality control. Our fast delivery times, with production of standard thickness pipes completed in as little as 7 days, meet the demands of time-sensitive projects. We offer complete certification, including API 5L, ISO 9001, ISO 14001, and more, meeting international standards. Thanks to our integrated production model and long-term partnerships with raw material suppliers, we maintain competitive pricing without compromising on quality. For top-tier carbon steel pipes that meet your project's exacting standards, contact us at info@longma-group.com.