Definition And Composition Of FBE Coating

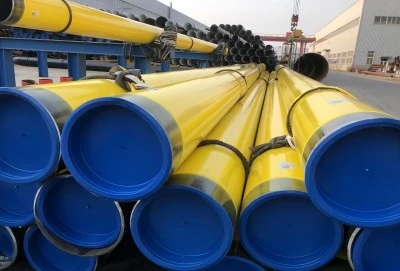

FBE steel pipe, or Fusion Bonded Epoxy, has emerged as a leading choice for coating steel pipes across various industries due to its remarkable protective properties. This high-performance coating is especially favored for its ability to safeguard against corrosion, chemical exposure, and physical wear. The primary components of FBE coating include epoxy resin, curing agents, and an array of additives designed to optimize its performance.

The epoxy resin serves as the foundational element of the coating, imparting exceptional adhesion and durability. This adhesion is critical, as it ensures that the coating adheres firmly to the steel surface, preventing delamination over time. Curing agents, typically composed of amines or polyamides, play a crucial role in initiating the cross-linking reaction that transforms the liquid coating into a solid, resilient layer. This cross-linking process is vital for achieving the desired mechanical and chemical resistance properties.

In addition to these primary ingredients, FBE coatings often contain various additives that enhance specific characteristics. For instance, pigments are incorporated not only for aesthetic purposes but also to provide UV protection, which can extend the coating's lifespan. Flow agents may be added to facilitate better application, ensuring a smooth finish that minimizes imperfections. Fillers can also be included to bolster properties like abrasion resistance, making the coating more suitable for harsh operating environments.

The application of FBE coatings typically results in a uniform thickness, ranging from 250 to 500 microns (10 to 20 mils). In particularly demanding applications, thicker coatings may be utilized to provide extra protection. The single-layer application of FBE is advantageous as it minimizes the risk of coating failure, creating a seamless barrier that effectively shields the steel substrate. Overall, FBE coatings contribute significantly to the longevity and reliability of FBE steel pipes, making them an indispensable choice for industries such as oil and gas, water transportation, and construction.

|

|

|

Process Flow Of FBE Coating

The application of steel pipes is a meticulous process that emphasizes careful control to ensure optimal performance and longevity in various applications. It begins with an essential surface preparation phase, which is critical for achieving excellent coating adhesion. This pretreatment stage consists of multiple steps, starting with abrasive blasting. This process effectively removes rust, mill scale, and other contaminants, creating a clean, roughened surface profile that significantly enhances the bonding capability of the coating. Once blasting is completed, the pipe surface is thoroughly cleaned, often employing methods such as compressed air or vacuum systems to eliminate dust and debris, ensuring no particles interfere with the coating process.

Following surface preparation, the actual coating stage employs advanced electrostatic spraying technology. In this phase, FBE powder is charged electrically as it is sprayed onto the grounded FBE steel pipe. The resulting charge difference causes the powder particles to adhere uniformly to the surface of the pipe, ensuring even coverage. After the application, the coated pipe is transported into a heating chamber, where temperatures typically range from 180°C to 250°C (356°F to 482°F). The application of heat causes the powder to melt and flow, forming a continuous film over the pipe surface.

As the coated pipe cools, a crucial curing phase begins, characterized by a complex cross-linking reaction within the epoxy material. This curing process is vital for developing the final properties of the coating. Key factors that influence the quality of solidification include curing temperature, curing time, and cooling rate. Proper management of these parameters is essential for achieving optimal cross-linking density, which directly impacts the coating's performance characteristics, including chemical resistance, mechanical strength, and overall durability. By adhering to this precise methodology, FBE-coated steel pipes are positioned to withstand harsh conditions and deliver exceptional longevity in service, making them a preferred choice for many industrial applications.

Excellent Performance Of FBE Coating

FBE coatings provide outstanding protection against corrosion, which is a primary concern for FBE steel pipes in various environments. The dense, cross-linked structure of the cured epoxy creates a formidable barrier against corrosive elements. FBE coatings exhibit excellent resistance to a wide range of chemicals, including acids, alkalis, and salts. This makes them suitable for use in diverse applications, from offshore oil pipelines exposed to saltwater to underground gas distribution systems in corrosive soils.

The mechanical properties of FBE coatings contribute significantly to their effectiveness and longevity. One of the key advantages is the exceptional adhesion to the steel substrate. This strong bond helps prevent coating delamination, even under challenging conditions. FBE coatings also demonstrate good flexibility, allowing them to withstand pipe movement and thermal expansion without cracking. Additionally, they offer impressive abrasion and impact resistance, protecting pipes during handling, installation, and service.

Electrical insulation is another valuable property of FBE coatings, particularly for applications in the energy sector. The high dielectric strength of the epoxy material effectively prevents electrical current flow between the pipe and its surroundings. This characteristic is crucial for maintaining the integrity of cathodic protection systems used to further prevent corrosion in buried or submerged pipelines. The insulating properties of FBE coatings also make them suitable for use in electrical conduit applications, where preventing current leakage is essential for safety and efficiency.

Contact Longma

LONGMA GROUP is a leading manufacturer specializing in FBE steel pipe, offering a diverse range of FBE coatings tailored to meet various industry demands. Their advanced expertise in FBE coating technology ensures that you receive optimal solutions for your specific applications, enhancing durability and performance. If you are interested in high-quality FBE-coated steel pipes or require more detailed information about their extensive product offerings, please feel free to contact LONGMA GROUP at info@longma-group.com for expert guidance.