A53 black steel pipe is a versatile and widely used type of carbon steel pipe in various industrial applications. Known for its strength, durability, and cost-effectiveness, this pipe is manufactured according to the ASTM A53 standard. It's commonly employed in the transportation of gas, oil, and water, as well as in structural applications. The "black" in its name refers to the dark oxide layer that forms on the pipe's surface during the manufacturing process, providing a basic level of corrosion protection.

|

|

|

Composition and Manufacturing Process Explained

Carbon Steel Alloy: Understanding A53 CompositionA53 black steel pipe is primarily composed of carbon steel, a versatile alloy known for its strength and formability. The exact composition can vary slightly, but typically includes iron as the base metal, with carbon content ranging from 0.25% to 0.30%. Other elements like manganese, phosphorus, and sulfur are present in smaller quantities, each contributing to the pipe's overall properties.

The carbon content plays a crucial role in determining the pipe's strength and weldability. Higher carbon content generally results in increased strength but may slightly reduce weldability. This balance is carefully managed to ensure the pipe meets the required performance standards while maintaining ease of fabrication and installation.

ERW vs. Seamless: A53 Pipe Manufacturing Methods

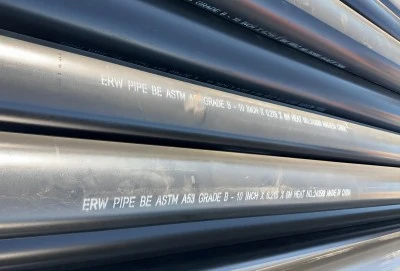

A53 black steel pipes are manufactured using two primary methods: Electric Resistance Welded (ERW) and seamless. The ERW process involves forming a flat steel strip into a cylindrical shape and welding the seam using electric current. This method is efficient and cost-effective, making it popular for producing pipes in large quantities.

Seamless pipes, on the other hand, are formed from a solid billet of steel that is pierced and rolled into a tubular shape without any welding. This process results in a pipe with uniform strength throughout its circumference, which can be advantageous in high-pressure applications.

ASTM Standards: Ensuring Quality in A53 Production

The production of A53 black steel pipes adheres to strict quality standards set by ASTM International. These standards cover various aspects of the pipe's manufacturing, including chemical composition, mechanical properties, and dimensional tolerances. Regular testing and inspection processes are implemented to ensure compliance with these standards, guaranteeing the reliability and performance of A53 pipes across different applications.

Quality control measures include tensile strength tests, flattening tests, and hydrostatic pressure tests. These rigorous checks help maintain the consistency and reliability of A53 black steel pipes, making them a trusted choice for critical infrastructure projects worldwide.

Key Properties: Strength, Durability, and Corrosion Resistance

Mechanical Strength: A53 Grade A vs. Grade B PipesA53 black steel pipes are available in two primary grades: Grade A and Grade B. The main difference between these grades lies in their mechanical properties, particularly their strength. Grade B pipes generally offer higher tensile and yield strengths compared to Grade A, making them suitable for more demanding applications.

Grade A pipes typically have a minimum yield strength of 30,000 psi and a minimum tensile strength of 48,000 psi. In contrast, Grade B pipes boast a minimum yield strength of 35,000 psi and a minimum tensile strength of 60,000 psi. This higher strength of Grade B pipes makes them the preferred choice for applications involving higher pressures or structural loads.

Durability in High-Pressure Applications

The durability of A53 black steel pipes in high-pressure environments is a key factor in their widespread use across various industries. These pipes can withstand significant internal pressures, making them ideal for transporting fluids and gases under high-pressure conditions. The pipe's wall thickness, determined by its schedule (e.g., Schedule 40 or Schedule 80), plays a crucial role in its pressure-bearing capacity.

In oil and gas applications, where high-pressure resistance is paramount, A53 pipes prove their worth. They maintain their structural integrity under extreme conditions, ensuring safe and efficient fluid transport. This durability extends to other high-stress applications, such as in industrial manufacturing processes and hydraulic systems.

Corrosion Resistance: Protecting A53 Black Steel Pipes

While A53 black steel pipes offer excellent strength and durability, their corrosion resistance is moderate compared to some other materials. The black oxide layer formed during manufacturing provides some initial protection, but additional measures are often necessary for long-term corrosion prevention, especially in harsh environments.

Common protection methods include galvanization, where a zinc coating is applied to the pipe's surface, creating a sacrificial layer that corrodes before the underlying steel. For more severe conditions, epoxy coatings or cathodic protection systems may be employed. Regular maintenance and inspection are crucial to identify and address any corrosion issues promptly, ensuring the longevity and safety of A53 pipe installations.

A53 vs. Other Steel Pipes: Comparing Standards

A53 vs. A106: Differences in Application and DesignWhile A53 and A106 steel pipes share similarities in composition and manufacturing processes, they are designed for different primary applications. A53 pipes are more versatile and commonly used in general-purpose applications, including water and gas transportation. A106 pipes, on the other hand, are specifically designed for high-temperature service in power plants and petrochemical facilities.

A106 pipes undergo additional heat treatment processes, enhancing their strength and durability at elevated temperatures. This makes them more suitable for applications involving steam or other high-temperature fluids. A53 pipes, while capable of handling moderate temperatures, are not typically recommended for extreme heat conditions without additional considerations.

A53 vs. A500: Structural Applications Compared

A53 and A500 steel pipes both find use in structural applications, but they are optimized for different scenarios. A53 pipes are primarily designed for fluid transport but can be used in some structural roles. A500 pipes, however, are specifically manufactured for structural use in buildings, bridges, and other load-bearing applications.

A500 pipes often have more stringent requirements for mechanical properties and dimensional tolerances compared to A53 pipes. They are available in various shapes, including square and rectangular profiles, making them more versatile for structural designs. A53 pipes, being round, are more commonly used in structural applications where their shape is advantageous, such as in scaffolding or temporary support structures.

A53 vs. A513: Mechanical Tubing Specifications

The comparison between A53 pipes and A513 mechanical tubing highlights the importance of selecting the right product for specific applications. A53 pipes are designed for pressure-bearing applications and structural use, while A513 tubing is primarily intended for mechanical applications where precise dimensional control is crucial.

A513 tubing often has tighter tolerances on wall thickness and outside diameter compared to A53 pipes. This precision makes A513 tubing ideal for applications in the automotive industry, hydraulic systems, and other mechanical components where exact fit and performance are critical. A53 pipes, with their focus on strength and pressure resistance, are better suited for larger-scale fluid transport and structural applications.

A53 black steel pipe stands as a cornerstone in the world of industrial piping and structural applications. Its blend of strength, durability, and versatility makes it an indispensable material across various sectors. From transporting vital resources like oil and gas to supporting critical infrastructure, A53 pipes continue to play a crucial role in modern industry. Understanding its properties, manufacturing processes, and how it compares to other standards is essential for engineers and project managers in making informed decisions. As industries evolve, A53 black steel pipe remains a reliable and cost-effective solution, adapting to new challenges while maintaining its core strengths.

Longma Group A53 Black Steel Pipe

For high-quality black steel pipes, look no further than Hebei Longma Group. Our state-of-the-art production facilities, equipped with advanced German machinery and four independently developed production lines, ensure top-notch quality and efficiency. Our team of over 300 skilled professionals, including 60+ technical experts, guarantees excellence in every pipe we produce. We boast comprehensive testing facilities, including ultrasonic flaw detectors and industrial X-ray equipment, ensuring each pipe meets stringent quality standards. With our ability to complete standard thickness pipe production in just 7 days and our complete range of certifications (API 5L, ISO 9001, ISO 14001, FPC, and more), we offer unparalleled service and reliability. Our competitive pricing, backed by stable raw material partnerships and an integrated production model, makes us the ideal choice for your A53 black steel pipe needs. For more information or to place an order, contact us at info@longma-group.com.