Purpose of OCTG tubing inspection:

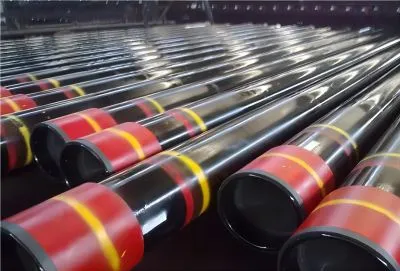

OCTG tubing inspection is a critical process in the oil and gas industry to ensure the quality, safety, and reliability of Oil Country Tubular Goods (OCTG). OCTG refers to a variety of pipes used in oil and gas wells, including casing, tubing, and drill pipes. The primary purpose of OCTG tubing inspection is to verify that these pipes meet the required specifications and standards before they are used in drilling operations.

The importance of OCTG tubing inspection cannot be overstated. In the harsh environments of oil and gas wells, where pipes are subjected to extreme pressures, temperatures, and corrosive substances, any defect or weakness can lead to catastrophic failures. These failures can result in significant financial losses, environmental damage, and even pose risks to human life. Therefore, rigorous inspection processes are essential to identify any flaws or deviations from specifications that could compromise the integrity of the tubing.

OCTG tubing inspection serves several key purposes: 1. Quality Assurance: It ensures that the tubing meets the required quality standards set by industry organizations such as the American Petroleum Institute (API). 2. Safety: By identifying defects or weaknesses, inspection helps prevent accidents and ensures the safety of workers and the environment. 3. Performance Optimization: Proper inspection ensures that the tubing will perform as expected under the specific conditions of the well. 4. Cost Efficiency: Early detection of defects can save companies significant costs by preventing failures and downtime during drilling operations. 5. Regulatory Compliance: Many jurisdictions require thorough inspection of OCTG tubing to comply with safety and environmental regulations.

|

|

|

Inspection content includes field inspection and testing of new tubing, casing and plain end drill pipe:

OCTG tubing inspection is a comprehensive process that involves both field inspection and testing of new tubing, casing, and plain end drill pipes. This multifaceted approach ensures that all aspects of the tubular goods are thoroughly examined before they are put into service.

Field inspection is typically the first step in the process. It involves visual examination of the tubing to check for any obvious defects or damage that may have occurred during manufacturing, transportation, or handling. Inspectors look for issues such as dents, scratches, thread damage, or any signs of corrosion. They also verify that the dimensions of the tubing, including length, diameter, and wall thickness, conform to the specified requirements.

In addition to visual inspection, field testing involves a range of non-destructive testing (NDT) methods to assess the integrity of the tubing without causing damage. Some common NDT techniques used in OCTG tubing inspection include: 1. Electromagnetic Inspection (EMI): This method uses electromagnetic fields to detect defects in the tubing wall. 2. Ultrasonic Testing (UT): High-frequency sound waves are used to detect internal flaws and measure wall thickness. 3. Magnetic Particle Inspection (MPI): This technique is used to detect surface and near-surface defects in ferromagnetic materials. 4. Eddy Current Testing: This method can detect surface and near-surface defects, as well as variations in material properties. 5. Hydrostatic Pressure Testing: This test checks the tubing's ability to withstand high pressures without leaking or failing.

For new tubing, casing, and plain end drill pipes, additional tests may be conducted to verify their mechanical properties. These may include tensile strength tests, hardness tests, and impact tests to ensure that the material meets the required specifications for strength and durability.

Inspection process uses technology:

The OCTG tubing inspection process leverages advanced technology to ensure accuracy, efficiency, and reliability. As the oil and gas industry continues to evolve, so do the technologies used in the inspection process.

One of the most significant technological advancements in OCTG tubing inspection is the use of automated inspection systems. These systems use a combination of sensors, cameras, and sophisticated software to perform high-speed, high-accuracy inspections. Automated systems can detect and measure defects that might be missed by human inspectors, and they can process large volumes of tubing much faster than manual inspection methods.

Digital radiography is another technology that has revolutionized OCTG tubing inspection. Unlike traditional film-based X-ray methods, digital radiography produces instant digital images that can be enhanced, analyzed, and stored electronically. This technology allows inspectors to detect internal defects with greater precision and efficiency.

Phased array ultrasonic testing (PAUT) is an advanced form of ultrasonic testing that uses multiple ultrasonic elements and electronic time delays to create beams with customizable angles, focal distances, and sizes. This technology provides more comprehensive and accurate inspections, especially for complex geometries and thicker materials.

Laser-based inspection systems are also gaining popularity in OCTG tubing inspection. These systems use laser technology to measure dimensions and detect surface defects with extremely high precision. They are particularly useful for inspecting thread connections, which are critical components of OCTG tubing.

In recent years, artificial intelligence (AI) and machine learning have begun to play a role in OCTG tubing inspection. These technologies can analyze inspection data to identify patterns and anomalies that might indicate potential defects or quality issues. AI can also help predict the likelihood of future failures based on historical inspection data, enabling more proactive maintenance and replacement strategies.

OCTG Tubing supplier:

Choosing the right OCTG tubing supplier is crucial for ensuring the quality and reliability of the tubular goods used in oil and gas operations. A reputable supplier should not only provide high-quality products but also demonstrate a commitment to rigorous inspection and testing processes.

Longma is one such supplier that offers OCTG tubing products that meet industry standards. Their products comply with API 5L and API 5CT standards, which are widely recognized in the oil and gas industry. API 5L specifies the requirements for seamless and welded steel line pipe, while API 5CT covers casing and tubing for use in oil and gas wells.

Longma offers products that meet API 5L and API 5CT standards. If you're in the process of choosing OCTG tubing manufacturers, you can contact them at info@longma-group.com for more information about their products and services.