X70 pipe represents a high-grade steel pipe specification within the API 5L standard, developed to meet the demanding requirements of modern oil and gas transmission pipelines. This grade designation indicates a minimum yield strength of 70,000 psi (483 MPa), positioning it among the higher-strength categories of line pipe materials. X70 pipe has gained significant prominence in long-distance pipeline projects where operational efficiency and material optimization are crucial factors.

The development of X70 pipe marked a significant advancement in pipeline technology, offering an optimal balance between strength, toughness, and weldability. These characteristics make it particularly suitable for high-pressure applications and challenging environmental conditions. The material's enhanced mechanical properties are achieved through careful control of chemical composition and sophisticated thermomechanical controlled processing (TMCP) during manufacture.

|

|

|

API 5L X70 Pipe Is A Premium Grade Piping Material In API 5L Standard Specifications

API 5L X70 pipe stands as a premium grade material within the API 5L standard specifications, representing advanced metallurgical engineering and manufacturing processes. The specification encompasses comprehensive requirements for chemical composition, mechanical properties, and manufacturing tolerances. The grade designation X70 signifies its minimum yield strength of 70,000 psi (483 MPa), while its minimum tensile strength typically ranges from 82,000 psi to 100,000 psi (565-690 MPa). These superior strength characteristics enable the design of pipeline systems with optimized wall thicknesses, potentially reducing material costs while maintaining operational safety.

The chemical composition of X70 pipe is carefully controlled to achieve the desired mechanical properties while maintaining good weldability. The carbon equivalent value (CEV) is typically maintained at levels that ensure excellent field weldability, crucial for pipeline construction. The microstructure of X70 steel is characterized by fine-grained ferrite-pearlite or acicular ferrite, developed through controlled rolling and cooling processes. This sophisticated microstructural control contributes to the material's exceptional combination of strength and toughness.

Quality control measures for X70 pipe production are particularly stringent, involving extensive testing and inspection protocols. These include mechanical testing, non-destructive examination, and hydrostatic testing to ensure compliance with specification requirements. The material must meet strict criteria for dimensional tolerances, surface condition, and internal quality to qualify as premium grade material under API 5L specifications.

API 5L X70 Covers Manufacturing Types In Seamless And Welded (ERW, SAW) Types

The manufacturing versatility of API 5L X70 pipe encompasses multiple production methods, each suited to specific applications and dimensional requirements. Seamless X70 pipes are manufactured through a process that doesn't involve welding, typically produced by hot forming steel billets into hollow sections through piercing and rolling operations. This manufacturing method is particularly valued for applications requiring maximum pressure containment capability and uniform material properties throughout the pipe circumference. The seamless production process demands precise control of temperature and deformation parameters to achieve the required X70 mechanical properties.

Welded X70 pipes are produced through Electric Resistance Welding (ERW) or Submerged Arc Welding (SAW) processes. ERW pipes are manufactured by cold-forming steel strip into a tubular shape and welding the longitudinal seam using high-frequency electric resistance welding. The SAW process, utilized for larger diameter pipes, involves forming steel plate into a tubular shape and welding both longitudinally (LSAW) or helically (HSAW). These welded manufacturing methods require sophisticated control of welding parameters and post-weld heat treatment to ensure the weld zone achieves properties matching or exceeding those of the base material.

Each manufacturing method brings specific advantages and considerations. The choice between seamless, ERW, or SAW X70 pipes depends on factors including diameter requirements, wall thickness, intended service conditions, and economic considerations. The manufacturing process selection significantly influences the final product's characteristics and suitability for specific applications.

X70 pipe Has Good Resistance To Hydrogen-Induced Cracking

The resistance of X70 pipe to hydrogen-induced cracking (HIC) represents a crucial material characteristic, particularly important for sour service applications where exposure to hydrogen sulfide (H2S) occurs. This resistance is achieved through careful control of steel cleanliness, microstructural features, and inclusion morphology during the manufacturing process. The material's resistance to HIC is enhanced by maintaining low levels of segregation-prone elements and utilizing advanced steelmaking practices to minimize harmful inclusions.

The microstructural design of X70 pipe plays a vital role in its HIC resistance. The fine-grained structure, typically achieved through thermomechanical controlled processing, provides numerous small-angle grain boundaries that help impede hydrogen diffusion and crack propagation. The distribution and morphology of inclusions are carefully controlled to minimize potential initiation sites for hydrogen-induced cracking. The combination of proper chemical composition and optimal microstructure results in a material with superior resistance to various forms of hydrogen damage.

Testing and qualification of X70 pipe for sour service applications involve rigorous procedures to verify its HIC resistance. These tests are conducted under standardized conditions that simulate actual service environments, ensuring the material's suitability for applications involving exposure to hydrogen sulfide. The qualification process includes an evaluation of the material's response to various hydrogen charging conditions and assessment of its resistance to different forms of hydrogen-induced damage.

X70 Pipe Supplier

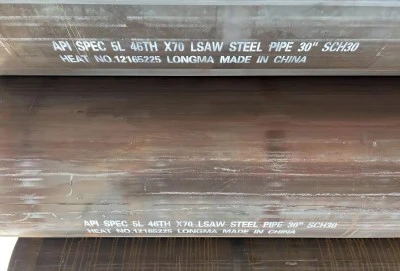

LONGMA GROUP has established itself as a prominent manufacturer and supplier of API 5L X70 pipe, offering both PSL1 and PSL2 grades to meet diverse project requirements. The company maintains comprehensive quality management systems and advanced manufacturing facilities capable of producing X70 pipe to stringent international standards. Their production capabilities encompass various manufacturing methods, including seamless, ERW, and SAW processes, allowing them to meet specific customer requirements for different applications.

Quality assurance at LONGMA GROUP involves sophisticated testing and inspection protocols, ensuring that every X70 pipe meets or exceeds API 5L specifications. The company maintains modern testing facilities and employs qualified personnel for conducting mechanical tests, non-destructive examinations, and dimensional verification. For technical inquiries and detailed product information, interested parties are encouraged to contact the sales team at info@longma-group.com.