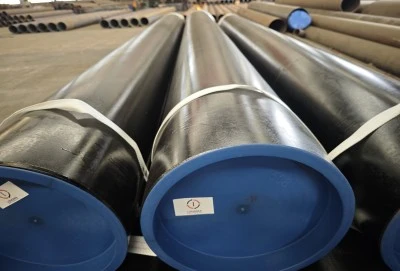

API 5L X52 pipe represents a crucial component in the oil and gas industry, specifically designed for pipeline transportation systems. This high-quality steel pipe is manufactured according to the American Petroleum Institute (API) 5L specification, which sets stringent standards for line pipe used in conveying gas, water, and oil. The X52 designation indicates its specific strength grade, making it suitable for various demanding applications in energy infrastructure projects. These pipes are characterized by their excellent mechanical properties, including high strength, good ductility, and superior weldability. Their reliable performance in demanding environments has made them a preferred choice for numerous pipeline projects worldwide, particularly in moderate-pressure applications and various climate conditions. The manufacturing process involves careful control of chemical composition and mechanical properties to ensure consistent quality and compliance with international standards. The extensive application of API 5L X52 pipes spans across multiple sectors, from oil and gas transmission to water distribution networks, showcasing their versatility and reliability in critical infrastructure development. Their proven track record in maintaining structural integrity under varying operational conditions has established them as a cornerstone in modern pipeline systems.

|

|

|

Also Called L360 Pipe

The API 5L X52 pipe is internationally recognized as an L360 pipe, particularly in regions following European or ISO standards. This alternative designation stems from the harmonization of international steel pipe standards, where L360 refers to the pipe's minimum yield strength of 360 MPa (megapascals). The dual nomenclature system enables global trade and specification compatibility across different regions and standards. Understanding this equivalency is essential for engineering professionals and procurement specialists working on international projects. The L360 designation is commonly used in European countries and regions that primarily follow ISO standards, while the X52 designation is more prevalent in North America and regions that traditionally follow API standards. This standardization has facilitated seamless international trade and project execution, allowing engineers and contractors worldwide to specify and source materials with confidence. The harmonization of standards has also contributed to quality consistency across different manufacturing regions, ensuring that pipes designated as either X52 or L360 meet the same rigorous performance criteria regardless of their origin.

The significance of this dual designation extends beyond mere nomenclature. It reflects the global nature of modern industrial projects and the need for standardized specifications that transcend geographical boundaries. The interchangeability of these designations has streamlined procurement processes, reduced confusion in international projects, and enhanced the efficiency of global supply chains. Furthermore, this standardization has fostered innovation in manufacturing processes and quality control methods, as manufacturers worldwide strive to meet the unified requirements of both designation systems.

X52 (L360) Named By Minimum Yield Strength

The designation X52 in API 5L X52 pipe directly correlates to its minimum yield strength requirement of 52,000 pounds per square inch (psi), or approximately 360 MPa. This naming convention follows the API's systematic approach to categorizing line pipes based on their mechanical properties. The yield strength represents the stress level at which the material begins to deform plastically, a critical parameter in pipeline design and operation. Modern manufacturing processes ensure that these pipes consistently meet or exceed these strength requirements through careful control of chemical composition, heat treatment, and forming processes. The relationship between chemical composition and mechanical properties is carefully balanced to achieve the desired strength while maintaining other essential characteristics such as weldability and toughness.

Quality control measures during production involve regular testing of mechanical properties, including yield strength, tensile strength, and elongation. These tests ensure that every pipe section meets the specified minimum yield strength requirements. The consistency in mechanical properties is crucial for the overall integrity and reliability of pipeline systems, particularly in applications where pressure fluctuations and environmental stresses are common. Advanced testing methodologies, including non-destructive evaluation techniques, are employed throughout the manufacturing process to verify compliance with strength requirements and detect any potential defects that could compromise performance.

The importance of maintaining precise yield strength specifications extends beyond basic operational requirements. It directly influences the pipeline's safety factor, long-term durability, and ability to withstand various environmental and operational stresses. The careful balance of alloying elements and processing parameters ensures that the final product not only meets the minimum yield strength requirements but also maintains optimal performance characteristics throughout its service life. This attention to detail in manufacturing and testing has contributed to the excellent safety record and reliability of pipelines constructed using X52 grade materials.

A Medium Grade In API 5L And ISO 3183 Specifications

Within the broader spectrum of API 5L and ISO 3183 specifications, X52 (L360) represents a medium-grade steel pipe, positioning itself as a versatile option for various pipeline applications. This grade offers an optimal balance between strength, cost-effectiveness, and ease of fabrication. The specification requirements cover aspects such as chemical composition, mechanical properties, hydrostatic test pressure, and dimensional tolerances. The medium-grade classification makes it particularly suitable for moderate-pressure applications in oil and gas transportation, water distribution systems, and structural applications. The specifications provide comprehensive guidelines for manufacturing processes, quality control procedures, and acceptance criteria, ensuring consistency across different manufacturers and regions.

The manufacturing of API 5L X52 pipes adheres to strict quality control procedures outlined in both API 5L and ISO 3183 standards. These specifications define acceptable ranges for chemical elements such as carbon, manganese, phosphorus, and sulfur, which directly influence the pipe's performance characteristics. The controlled chemistry ensures good weldability and resistance to various forms of degradation, including corrosion and stress-induced damage. Modern production facilities employ advanced process control systems and automation to maintain precise control over manufacturing parameters, resulting in consistent product quality and performance reliability.

The medium-grade designation of X52 pipes represents a carefully considered balance between performance requirements and economic considerations. This grade has proven particularly successful in applications where extreme high-strength grades would be excessive, yet standard grades would be insufficient. The specifications also address important aspects such as pipe end finishing, surface condition, and marking requirements, ensuring that the final product is suitable for its intended application and can be properly identified and traced throughout its service life. Additionally, the standards provide guidance for supplementary requirements that may be specified for particular applications, allowing for customization while maintaining fundamental quality and performance criteria.

Wholesale API 5L x52 Steel Pipe Exporter

LONGMA GROUP has established itself as a prominent manufacturer and exporter of API 5L X52 steel pipes, maintaining high standards of quality and reliability in the global market. Their manufacturing facilities are equipped with advanced technology and quality control systems to ensure consistent product quality. The company's commitment to excellence is demonstrated through its comprehensive certification portfolio, including API 5L Certificate, ISO Certificate, and QMS Certificate, which validate their adherence to international quality standards and manufacturing practices. Their state-of-the-art production facilities incorporate the latest advances in pipe manufacturing technology, enabling them to meet diverse customer requirements while maintaining stringent quality standards.

The company's expertise in producing API 5L X52 pipes extends to various dimensions and specifications, catering to diverse project requirements worldwide. Their quality management system ensures thorough inspection and testing at every stage of production, from raw material selection to final product inspection. For organizations seeking reliable API 5L X52 steel pipe suppliers, LONGMA GROUP offers professional consultation and technical support through their dedicated communication channel at info@longma-group.com. The company's commitment to customer satisfaction is reflected in its comprehensive technical support services, which include detailed product documentation, engineering consultation, and after-sales support.

LONGMA GROUP's success in the global market is built on its ability to consistently deliver high-quality products while maintaining competitive pricing and reliable delivery schedules. Their export operations are supported by efficient logistics networks and strategic partnerships with shipping companies, ensuring timely delivery to customers worldwide. The company's quality assurance program includes regular third-party inspections and certifications, providing customers with additional confidence in the integrity and reliability of their products. Their technical team stays current with industry developments and regulatory requirements, enabling them to provide valuable insights and recommendations to customers regarding product selection and application considerations.