API 5L X65 pipe specification represents a high-grade steel pipe standard established by the American Petroleum Institute (API). These pipes serve as critical components in modern pipeline infrastructure, particularly in the oil and gas industry where reliability and performance are paramount. The specification encompasses comprehensive requirements for seamless and welded steel line pipes, defining strict parameters for chemical composition, mechanical properties, manufacturing processes, and quality control measures.

The development of X65 grade steel pipes marked a significant advancement in pipeline technology, offering an optimal balance between strength, weldability, and cost-effectiveness. These pipes undergo rigorous manufacturing processes, including precise heat treatment and controlled cooling, ensuring consistent material properties throughout their structure. The specification covers various aspects including dimensional tolerances, surface conditions, end finishing, hydrostatic testing, and non-destructive examination requirements.

|

|

|

High Minimum Tensile Strength Of 450 MPA

API 5L X65 pipes demonstrate exceptional performance through their impressive minimum tensile strength of 450 MPa. This remarkable strength characteristic stems from advanced metallurgical engineering and precise manufacturing controls. The high tensile strength enables these pipes to maintain structural integrity under extreme pressure conditions, temperature variations, and complex loading scenarios commonly encountered in pipeline operations.

The microstructure of X65 grade steel exhibits a carefully engineered composition of fine-grained ferrite-pearlite, achieved through controlled rolling and accelerated cooling processes. The refined grain structure contributes significantly to the material's superior mechanical properties. Key alloying elements include carefully balanced proportions of carbon (typically 0.16% maximum), manganese (1.65% maximum), and micro-alloying elements such as niobium, vanadium, and titanium, which play crucial roles in grain refinement and precipitation strengthening.

Recent metallurgical studies have revealed that the superior tensile strength of X65 pipes results from multiple strengthening mechanisms working in concert. These include grain boundary strengthening, precipitation hardening, and dislocation strengthening. The combination of these mechanisms creates a robust microstructure capable of withstanding high internal pressures while maintaining excellent resistance to environmental factors.

Laboratory testing protocols for X65 pipes include extensive tensile testing, impact testing, and hardness measurements. These tests consistently demonstrate uniform strength properties across the pipe body and weld zones. The high tensile strength particularly benefits deep-water pipeline applications where external pressure resistance becomes critical.

Stronger Than API 5L GR. X60 pipe

API 5L X65 pipes showcase superior mechanical properties compared to X60 grade pipes across multiple performance parameters. The enhanced yield strength requirement of 448 MPa (65,000 psi) for X65 grade, versus 414 MPa (60,000 psi) for X60 grade, represents a significant advancement in pipeline material technology. This strength differential translates into improved operational capabilities and enhanced safety margins.

The manufacturing process for X65 pipes incorporates sophisticated thermo-mechanical controlled processing (TMCP) techniques. This advanced processing method involves precise control of deformation and cooling rates during production, resulting in optimized grain structure and improved mechanical properties. The TMCP process enables achievement of higher strength levels while maintaining excellent toughness and weldability characteristics.

Comparative analysis between X65 and X60 pipes reveals superior performance in several key areas. X65 pipes demonstrate enhanced resistance to strain aging, improved low-temperature toughness, and better fatigue resistance. These improvements stem from the refined microstructure and optimized chemical composition achieved through advanced manufacturing processes.

Field performance data collected from various pipeline projects worldwide indicates that X65 pipes consistently outperform X60 pipes in challenging environmental conditions. The higher strength grade provides additional resistance to external mechanical damage and better stability under cyclic loading conditions typical in modern pipeline operations.

Cost-Effective In Long Term

The economic advantages of API 5L X65 pipes extend well beyond their initial acquisition costs. Comprehensive lifecycle cost analyses demonstrate significant long-term benefits through reduced maintenance requirements, extended service life, and improved operational efficiency. The superior mechanical properties of X65 pipes often allow for optimization of wall thickness, resulting in material savings without compromising performance or safety.

Advanced corrosion resistance properties of X65 pipes contribute substantially to their long-term cost-effectiveness. The material's carefully controlled chemical composition and manufacturing processes result in improved resistance to various forms of corrosion, including stress corrosion cracking and hydrogen-induced cracking. This enhanced corrosion resistance translates into reduced maintenance costs and extended service intervals.

Operational cost benefits of X65 pipes include the potential for higher operating pressures, enabling increased throughput capacity in pipeline systems. The improved pressure ratings often allow operators to optimize pumping station spacing and reduce energy consumption in long-distance pipeline networks. These operational advantages contribute to improved return on investment over the pipeline system's lifecycle.

Real-world case studies from major pipeline projects demonstrate the economic benefits of X65 pipes. Projects utilizing X65 grade materials have reported reduced inspection and maintenance requirements, lower repair frequencies, and extended service life compared to installations using lower-grade materials. The combination of these factors results in favorable total cost of ownership metrics despite higher initial investment.

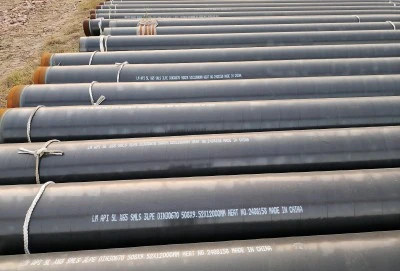

API 5L X65 Pipe For Sale

LONGMA GROUP maintains comprehensive manufacturing capabilities for API 5L X65 pipes, offering both PSL1 and PSL2 quality levels to meet diverse project requirements. The manufacturing facility incorporates state-of-the-art equipment and quality control systems, ensuring consistent production of high-quality pipes that meet or exceed API specifications.

PSL1 specification provides standard quality requirements suitable for regular pipeline applications. This level includes basic chemical composition requirements, tensile testing, and hydrostatic testing. PSL2 specification introduces additional requirements including stricter controls on chemical composition, expanded mechanical testing, and comprehensive non-destructive examination procedures.

The manufacturing process at LONGMA GROUP incorporates multiple quality control checkpoints, ensuring compliance with API standards and customer specifications. Each production batch undergoes rigorous testing and inspection procedures, including ultrasonic testing, radiographic examination, and mechanical property verification. The quality assurance system maintains full traceability from raw material through final product delivery.

Product offerings include a wide range of pipe dimensions and wall thicknesses, accommodating various project specifications. The manufacturing capability extends to both seamless and welded pipe configurations, with available outside diameters ranging from 60.3mm to 1219.2mm. Wall thickness options span from 4.8mm to 50.8mm, providing flexibility for different pressure rating requirements. If you are choosing your api 5l x65 pipe manufacturers, welcome to contact us at info@longma-group.com.