In the world of industrial piping and tubing, the American Society for Testing and Materials (ASTM) plays a crucial role in setting standards for material quality and performance. ASTM pipe grades are essential for engineers, manufacturers, and end-users to ensure that the pipes they use meet specific requirements for various applications. This comprehensive guide will delve into the ASTM grading system for pipes, explore the meaning behind ASTM grade designations, and discuss performance and application considerations based on different grades.

|

|

|

The ASTM Grading System for Pipes: An Overview

The ASTM International, formerly known as the American Society for Testing and Materials, is a globally recognized organization that develops and publishes technical standards for a wide range of materials, products, systems, and services. In the context of pipes and tubing, ASTM standards provide a systematic approach to classifying and specifying materials based on their chemical composition, mechanical properties, and intended use.

The ASTM grading system for pipes is designed to ensure consistency, reliability, and safety across various industries. It helps manufacturers produce pipes that meet specific requirements and allows end-users to select the most appropriate materials for their applications. The system covers a wide range of materials, including carbon steel, stainless steel, aluminum, and various alloys.

ASTM standards for pipes typically include specifications for dimensions, tolerances, chemical composition, mechanical properties, and testing methods. These standards are regularly updated to reflect advancements in technology and changes in industry requirements.

For example, ASTM A53 is a common standard for carbon steel pipes used in various applications, including the transmission of fluids and gases. This standard covers seamless and welded black and hot-dipped galvanized steel pipe in nominal pipe sizes NPS 1/8 to NPS 26.

Decoding ASTM Pipe Grade Designations

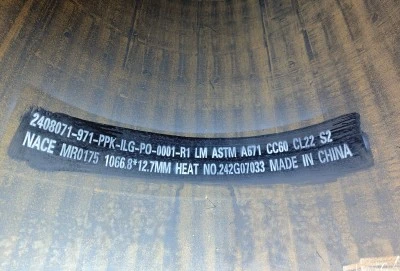

ASTM pipe grade designations consist of a combination of letters and numbers that provide information about the material's properties and intended use. Understanding these designations is crucial for selecting the right pipe for a specific application. Let's break down the components of an ASTM pipe grade designation:

- ASTM Prefix: The designation typically starts with "ASTM" followed by a letter (e.g., A, B, C) indicating the general material category.

- Standard Number: A three or four-digit number follows, representing the specific standard (e.g., ASTM A106).

- Grade: Many standards include different grades, usually designated by letters or numbers (e.g., Grade A, Grade B, Grade X42).

- Additional Information: Some designations may include additional letters or numbers to indicate specific properties or manufacturing methods.

For instance, ASTM A106 Grade B is a common specification for seamless carbon steel pipe for high-temperature service. In this designation:

- "A" indicates ferrous materials

- "106" is the specific standard for seamless carbon steel pipe

- "Grade B" specifies the particular grade within the A106 standard

Another example is ASTM A53 Grade B, which is widely used for general-purpose pipe applications. This grade is known for its good weldability and formability, making it suitable for various structural and mechanical applications.

It's important to note that while ASTM standards are widely used in North America, other regions may use different systems, such as EN (European Norms) or JIS (Japanese Industrial Standards). However, many of these standards are harmonized or have equivalent ASTM grades to facilitate international trade and consistency in material specifications.

Performance and Application Considerations Based on ASTM Pipe Grades

Selecting the appropriate ASTM pipe grade is crucial for ensuring optimal performance and longevity in specific applications. Different grades offer varying levels of strength, ductility, corrosion resistance, and temperature tolerance. Here are some key considerations when choosing ASTM pipe grades:

- Mechanical Properties: ASTM grades specify minimum requirements for yield strength, tensile strength, and elongation. Higher-grade materials generally offer greater strength but may be less ductile.

- Chemical Composition: The alloying elements in the pipe material affect its properties, such as corrosion resistance and weldability.

- Temperature Range: Some grades are specifically designed for high-temperature or low-temperature service.

- Pressure Rating: The pipe's ability to withstand internal pressure is crucial for many applications, particularly in the oil and gas industry.

- Corrosion Resistance: Certain grades, particularly in stainless steel, offer enhanced resistance to specific types of corrosion.

- Weldability: For applications requiring on-site fabrication or assembly, the pipe's weldability is an important consideration.

For example, in the oil and gas industry, ASTM A106 Grade B is commonly used for high-temperature applications due to its excellent strength and durability at elevated temperatures. On the other hand, ASTM A312 is a standard for austenitic stainless steel pipe, with grades like TP304 and TP316 offering excellent corrosion resistance for chemical processing and food industry applications.

In the realm of ASTM tubing, which refers to smaller diameter pipes often used in heat exchangers, hydraulic systems, and instrumentation, the choice of grade is equally important. For instance, ASTM A179 is a standard for seamless cold-drawn low-carbon steel tubes used in heat exchangers and condensers, while ASTM A213 covers seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes.

When selecting an ASTM pipe or tubing grade, it's essential to consider the specific requirements of your application, including:

- Operating temperature and pressure

- Environmental conditions (e.g., exposure to corrosive substances)

- Regulatory requirements for the industry or application

- Cost considerations and material availability

- Fabrication and installation methods

Consulting with materials engineers or suppliers can help ensure that you choose the most appropriate ASTM grade for your specific needs.

Understanding ASTM pipe grades is crucial for anyone involved in the selection, specification, or use of industrial piping and tubing. The ASTM grading system provides a standardized framework for ensuring material quality, consistency, and performance across a wide range of applications. By decoding ASTM grade designations and considering the performance characteristics of different grades, engineers and end-users can make informed decisions that optimize safety, efficiency, and longevity in their piping systems.

As technology advances and industry requirements evolve, staying up-to-date with the latest ASTM standards and grades is essential. Whether you're working with carbon steel pipes for general industrial use or specialized alloy tubing for high-performance applications, the ASTM grading system provides the guidance needed to select the right materials for the job.

For high-quality steel pipes that meet rigorous ASTM standards, consider Longma Group, one of China's leading ERW/LSAW steel pipe manufacturers since 2003. Specializing in the production of large-diameter, thick-walled, double-sided, sub-arc-seam welding steel pipe, LSAW (Longitudinal Submerged Arc Welded), and ERW steel pipes, Longma Group has established itself as a reliable supplier in the industry. With an annual output exceeding 1,000,000 tons by the end of 2023, Longma Group has the capacity to meet diverse industrial needs. For more information or to discuss your specific requirements, please contact us at info@longma-group.com.