Black pipe, also known as black coated steel pipe, is primarily composed of carbon steel. This versatile material is widely used in various industries, including oil and gas transportation, water supply systems, and industrial manufacturing. The pipe's distinctive black appearance comes from a protective layer formed during the manufacturing process, enhancing its corrosion resistance and durability.

|

|

|

Carbon Steel: The Core of Black Pipe

At the heart of black pipe lies carbon steel, a material renowned for its strength, durability, and cost-effectiveness. This alloy, primarily composed of iron and carbon, forms the backbone of countless industrial applications worldwide. Let's delve deeper into the key aspects that make carbon steel the ideal choice for black pipe manufacturing.

High Carbon Content: Key to Strength and Durability

The high carbon content in black pipe is crucial for its impressive strength and durability. Typically ranging from 0.25% to 0.55%, this elevated carbon level contributes to the pipe's ability to withstand high pressures and resist deformation under stress. For pipeline engineers and project managers overseeing large-scale transportation systems, this strength translates to increased reliability and longevity of the infrastructure.

Alloying Elements: Enhancing Black Pipe Properties

While carbon is the primary alloying element, manufacturers often incorporate small amounts of other elements to enhance specific properties of black pipe. Manganese, for instance, improves hardenability and wear resistance, while silicon can boost strength without compromising ductility. These carefully balanced additions make black pipe suitable for diverse applications, from offshore platforms to building structures.

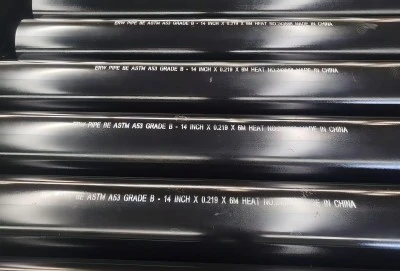

Grade A vs Grade B: Choosing the Right Carbon Steel

When selecting black pipe for a project, understanding the differences between Grade A and Grade B carbon steel is essential. Grade A, with its lower carbon and manganese content, offers excellent formability and weldability, making it ideal for applications requiring frequent bends or joints. Grade B, on the other hand, boasts higher strength due to its increased carbon and manganese levels, making it suitable for high-pressure applications in the oil and gas industry. Plant equipment managers must consider these grades carefully to ensure optimal performance in their specific operational environments.

Manufacturing Process: From Raw Material to Finished Product

The journey from raw carbon steel to finished black pipe involves a series of sophisticated manufacturing processes. Each step is crucial in determining the final product's quality, performance, and suitability for various applications. For procurement managers and contractors involved in large-scale engineering projects, understanding this process is key to making informed decisions about pipe selection and quality assurance.

ERW vs LSAW: Black Pipe Production Techniques

Two primary methods dominate the production of black pipe: Electric Resistance Welding (ERW) and Longitudinal Submerged Arc Welding (LSAW). ERW is typically used for smaller diameter pipes, offering a cost-effective solution for many applications. The process involves passing an electric current through the edges of rolled steel to create a high-quality weld seam. LSAW, on the other hand, is preferred for larger diameter pipes and high-pressure applications. This method uses multiple welding arcs submerged in flux, resulting in a strong, uniform weld ideal for demanding environments like offshore oil platforms.

Heat Treatment: Optimizing Black Pipe Performance

After welding, black pipes undergo heat treatment to optimize their mechanical properties. This process, which may include normalizing, quenching, and tempering, helps relieve internal stresses, improve grain structure, and enhance overall strength and toughness. For structural engineers working on bridge or building projects, this step ensures the pipes can withstand the complex loads and environmental stresses they'll face throughout their service life.

Surface Coating: Creating the Distinctive Black Finish

The final stage in black pipe manufacturing involves creating its characteristic black surface. This is typically achieved through a controlled oxidation process or by applying a protective coating. The resulting black layer not only gives the pipe its name but also serves as a crucial first line of defense against corrosion. This feature is particularly valuable for pipes used in water supply systems or exposed to harsh environmental conditions in industrial settings.

Composition Analysis: Black Pipe Properties

A thorough understanding of black pipe's composition is crucial for engineers and project managers to make informed decisions about its application in various industrial settings. This analysis goes beyond just knowing the primary material; it involves a deep dive into the chemical makeup, mechanical characteristics, and corrosion resistance properties that define the performance of black coated steel pipe in real-world scenarios.

Chemical Composition: Balancing Strength and Weldability

The chemical composition of black pipe is carefully balanced to achieve optimal strength without compromising weldability. While carbon is the primary alloying element, providing strength and hardness, its content is typically kept below 0.3% to maintain good weldability. Manganese, usually present in amounts between 0.6% and 1.65%, enhances strength and hardenability. Small amounts of silicon (0.1% to 0.35%) improve deoxidation during the steelmaking process. Trace elements like phosphorus and sulfur are strictly controlled to prevent embrittlement and ensure the pipe's integrity under various operational conditions.

Mechanical Properties: Tensile Strength and Ductility

The mechanical properties of black pipe are crucial for its performance in high-stress environments. Tensile strength, typically ranging from 330 to 485 MPa for standard grades, ensures the pipe can withstand high internal pressures common in oil and gas transportation. Yield strength, usually between 205 and 360 MPa, indicates the pipe's ability to resist permanent deformation under load. Ductility, measured by elongation (minimum 20% for most grades), is essential for the pipe's ability to withstand bending and forming operations during installation. These properties make black pipe a versatile choice for various applications, from water supply systems to structural supports in large-scale construction projects.

Corrosion Resistance: Black Pipe in Harsh Environments

While not as corrosion-resistant as stainless steel, black pipe offers significant protection against rust and degradation, particularly in indoor applications or when properly coated. The black oxide layer formed during manufacturing provides a basic level of corrosion resistance. For more demanding environments, such as offshore platforms or underground pipelines, additional protective measures like cathodic protection or specialized coatings are often employed. Understanding the corrosion resistance of black pipe is crucial for project managers and engineers working in regions with challenging environmental conditions, such as the Middle East or Southeast Asia, where exposure to salt water or corrosive soils is common.

Black coated steel pipe, with its foundation in carbon steel, offers a robust and versatile solution for various industrial applications. Its composition, carefully engineered through alloying and manufacturing processes, provides an optimal balance of strength, weldability, and corrosion resistance. For professionals in pipeline engineering, project procurement, and plant equipment management, understanding the intricacies of black pipe composition and properties is crucial for making informed decisions. As global infrastructure continues to expand, particularly in regions like the Middle East, Australia, and Southeast Asia, the role of black pipe in ensuring efficient and durable systems remains paramount.

Black Coated Steel Pipe Manufacturer

When sourcing high-quality black coated steel pipe for your projects, consider Hebei Longma Group, a leading manufacturer in the field. With advanced production equipment imported from Germany and four independently developed production lines, Hebei Longma Group ensures top-notch quality and efficiency. Their professional team of over 300 employees, including 60+ technical experts, guarantees expert guidance and support. Comprehensive testing facilities, including ultrasonic flaw detectors and X-ray equipment, ensure product integrity. With fast delivery times as short as for standard thickness pipes and a complete range of certifications, including API 5L and ISO 9001, Hebei Longma Group offers reliability and quality assurance. Their competitive pricing, backed by stable raw material partnerships and efficient production processes, makes them an excellent choice for your black coated steel pipe needs. For more information or to place an order, contact us at info@longma-group.com.