ERW pipe specification refers to the standardized guidelines and requirements for Electric Resistance Welded (ERW) pipes used in various industries. These specifications outline the manufacturing process, material properties, dimensions, and quality control measures for ERW pipes. Understanding these specifications is crucial for engineers, procurement managers, and contractors working in oil and gas transportation, water supply systems, and industrial manufacturing sectors.

|

|

|

ERW Pipe Standards

ERW pipe standards are essential for ensuring consistency, quality, and reliability in pipe manufacturing and applications. These standards provide a common language for manufacturers, suppliers, and end-users, enabling seamless communication and project execution.

API 5L: The Gold Standard for ERW Pipes

The American Petroleum Institute's API 5L specification is widely regarded as the gold standard for ERW pipes in the oil and gas industry. This standard covers the manufacturing, testing, and qualification of welded steel pipes for use in pipeline transportation systems. API 5L defines various grades of steel, such as X42, X52, and X70, each with specific mechanical properties and chemical compositions. The standard also outlines requirements for pipe dimensions, tolerances, and non-destructive testing methods to ensure pipe integrity.

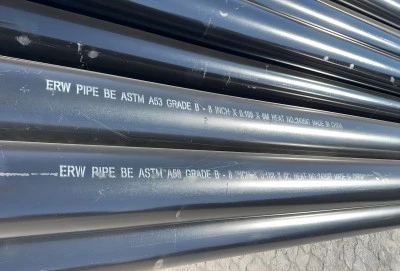

ASTM A53: Specifications for ERW Carbon Steel Pipes

ASTM A53 is a standard set by the American Society for Testing and Materials (ASTM) International. It covers welded and seamless carbon steel pipes for various applications, including mechanical and pressure purposes. ASTM A53 specifies three types of pipes: Type E (ERW), Type F (furnace-welded), and Type S (seamless). This standard provides guidelines for chemical composition, tensile strength, yield strength, and elongation properties of the pipes. ASTM A53 is commonly used in the construction industry and for general-purpose piping systems.

ISO 3183: Global Standard for ERW Line Pipes

The International Organization for Standardization (ISO) 3183 standard is a globally recognized specification for steel pipe used in pipeline transportation systems. This standard covers both seamless and welded steel pipes, including erw pipes. ISO 3183 defines material grades, manufacturing processes, and testing requirements for pipes used in the oil and gas industry. It also provides guidelines for pipe dimensions, tolerances, and quality control measures. The ISO 3183 standard is particularly important for international projects and helps ensure compatibility between pipes manufactured in different countries.

Key Dimensions and Tolerances Explained

Understanding the key dimensions and tolerances of ERW pipes is crucial for ensuring proper fit, function, and performance in various applications. Let's explore the critical measurements and quality parameters that define ERW pipe specifications:

Diameter and Wall Thickness: Critical ERW Pipe Measurements

The diameter and wall thickness of ERW pipes are fundamental measurements that determine their strength, capacity, and suitability for specific applications. The outside diameter (OD) is the distance across the circular cross-section of the pipe, while the wall thickness is the distance between the inner and outer surfaces of the pipe wall. These dimensions are typically specified in inches or millimeters and must adhere to strict tolerances to ensure proper fit and function.

For example, API 5L specifies that the outside diameter tolerance for ERW pipes with OD less than or equal to 168.3 mm (6.625 inches) should be ±0.79 mm (±1/32 inch). The wall thickness tolerance is typically ±12.5% for pipes with a specified wall thickness less than 5 mm (0.197 inches) and ±10% for thicker pipes. These tight tolerances are crucial for maintaining consistent pipe performance and facilitating seamless connections in pipeline systems.

Length Tolerances: Meeting Industry Requirements

The length of ERW pipes is another critical dimension that must meet specific tolerances to ensure proper installation and system design. Pipe lengths are typically specified as either random lengths or cut-to-length, depending on the application requirements. Random lengths are usually supplied in ranges, such as 20-40 feet, while cut-to-length pipes are manufactured to precise specifications.

Length tolerances for ERW pipes vary depending on the standard and the specified length. For instance, ASTM A53 allows a length tolerance of ±1/4 inch for cut-to-length pipes under 20 feet, and ±1/2 inch for pipes 20 feet and over. These tolerances are essential for ensuring accurate pipe layout and minimizing waste during installation.

Ovality and Straightness: Ensuring Pipe Quality

Ovality and straightness are crucial quality parameters for erw pipes, affecting their performance and ease of installation. Ovality refers to the difference between the maximum and minimum outside diameters measured at the same cross-section of the pipe. Excessive ovality can lead to difficulties in pipe joining and reduced pressure capacity.

API 5L specifies that the maximum permissible ovality for ERW pipes should not exceed 1% of the specified outside diameter. For pipes with an OD greater than 168.3 mm (6.625 inches), the ovality limit is 0.8% of the OD.

Straightness is another important factor, especially for long pipe sections. API 5L requires that the maximum deviation from a straight line for the total length of pipe should not exceed 0.2% of the pipe length. Ensuring proper straightness is crucial for maintaining pipeline alignment and reducing stress on pipe joints.

Choosing the Right ERW Pipe Specification

Selecting the appropriate ERW pipe specification is a critical decision that can significantly impact project success, cost-effectiveness, and long-term performance. Let's explore the key factors to consider when choosing ERW pipe specifications:

Material Grade Selection: Balancing Strength and Cost

The material grade of ERW pipes determines their strength, durability, and suitability for specific applications. Common grades include API 5L X42, X52, X60, and X70, with higher numbers indicating greater strength. When selecting a material grade, consider factors such as operating pressure, temperature, and environmental conditions.

For example, X42 grade may be suitable for low-pressure water supply systems, while X70 grade is often used in high-pressure oil and gas pipelines. It's important to balance the required strength with cost considerations, as higher-grade materials typically come at a premium. Consulting with experienced engineers and suppliers can help in making informed decisions based on project requirements and budget constraints.

End Finish Options: Plain, Beveled, or Threaded

The end finish of ERW pipes plays a crucial role in determining the joining method and overall system design. Common end finish options include:

- Plain Ends: Suitable for welding or mechanical coupling connections

- Beveled Ends: Facilitate easier and stronger welded joints

- Threaded Ends: Allow for quick assembly and disassembly in certain applications

The choice of end finish depends on factors such as installation method, maintenance requirements, and system flexibility. For instance, beveled ends are often preferred in permanent pipeline installations, while threaded ends may be more suitable for temporary or frequently modified piping systems.

Coating Considerations: Enhancing Corrosion Resistance

Coatings play a vital role in protecting erw pipes from corrosion and extending their service life. Common coating options include:

- Fusion Bonded Epoxy (FBE): Provides excellent corrosion protection for buried pipelines

- Galvanization: Offers good corrosion resistance for above-ground applications

- Three-Layer Polyethylene (3LPE): Combines corrosion protection with mechanical damage resistance

When selecting a coating, consider factors such as soil conditions, exposure to chemicals, and operating temperatures. It's also important to ensure compatibility between the coating and any cathodic protection systems used in the pipeline.

Understanding ERW pipe specifications is crucial for professionals in the oil and gas, water supply, and industrial manufacturing sectors. By familiarizing yourself with key standards like API 5L, ASTM A53, and ISO 3183, you can make informed decisions about pipe selection and ensure project success. Remember to consider critical factors such as dimensions, tolerances, material grades, end finishes, and coatings when choosing ERW pipes for your applications. With this knowledge, you'll be better equipped to navigate the complexities of pipeline and structural engineering projects.

ERW Pipes For Sale

Looking for high-quality ERW pipes that meet stringent industry standards? Hebei Longma Group offers a wide range of ERW pipes manufactured using advanced production equipment imported from Germany. Our professional team of over 300 employees, including 60+ technical experts, ensures top-notch quality and innovation in pipe manufacturing. We boast comprehensive testing facilities, including online ultrasonic automatic flaw detectors and industrial X-ray television, guaranteeing the integrity of every pipe we produce. With our efficient production process, we can deliver standard thickness steel pipes in as little as 7 days. Our products come with complete certifications, including API 5L, ISO 9001, ISO 14001, and more. Thanks to our long-term partnerships with raw material suppliers and integrated production model, we offer competitive prices without compromising on quality. For more information about our ERW pipes, contact us at info@longma-group.com.