The structural steel pipe is a necessity for modern construction and engineering tasks because it provides an exceptional blend of strength, adaptability, and economy. Whether you're a seasoned professional in the construction industry or simply curious about building materials, understanding structural steel pipe is essential. We are going over what metallic pipe is, how to select and use it, and the laws that govern its production and utilization in this detailed guide.

|

|

|

What is Structural Steel Pipe?

Structural steel pipe, additionally referred to as structural piping or empty structure sections (HSS), is a type of steel tube that is frequently used for construction and construction. Unlike standard pipes designed for fluid transport, these pipes are engineered to bear significant loads and provide structural support in buildings, bridges, and other large-scale projects.

These conduits have a high strength-to-weight proportion, which makes them perfect for applications needing both endurance and cost concerns. Architectural steel pipes are typically composed of carbon or steel alloys, which go through rigorous production processes to guarantee the same level of performance and quality.

One of the key advantages of a structural steel pipe is its versatility. It is accessible in an array of forms, including square, circle, and rectangular profiles, each one providing different benefits based on what is being used. Circular pipes, for instance, are excellent for resisting torsional forces, while square and rectangular profiles provide flat surfaces that are easier to connect to other structural elements.

Selection And Use Of Structural Steel Pipes

Choosing the right structural steel pipe for a project requires careful consideration of several factors. The selection process typically involves assessing the intended application, load-bearing requirements, environmental conditions, and budget constraints. Here are some key considerations when selecting and using these pipes:

1. Size and Shape: The dimensions and profile of the structural steel pipe play a crucial role in its performance. Larger diameters and wall thicknesses generally offer greater strength, but they also increase weight and cost. The shape (circular, square, or rectangular) should be chosen based on the specific structural requirements and aesthetic considerations of the project.

2. Material Grade: these pipes are available in various grades, each with different mechanical properties. Common grades include ASTM A500, A513, and A53. The choice of grade depends on factors such as required strength, ductility, and weldability.

3. Surface Finish: Depending on the application, structural steel pipes may require different surface finishes. Options include hot-dipped galvanized for corrosion resistance, painted for aesthetic purposes, or left as bare steel for indoor applications.

4. Connection Methods: Consider how the structural steel pipes will be joined to other elements. Common connection methods include welding, bolting, and using specialized connectors. The chosen method can impact the overall design and installation process.

5. Load-bearing Capacity: Assess the expected loads that the structural pipe will need to support. This includes dead loads (constant weight), live loads (variable weight), and dynamic loads (such as wind or seismic forces).

When it comes to using structural steel pipes, they find applications in a wide range of projects. In building construction, they're often used for columns, beams, and trusses. In infrastructure projects, the products are employed in bridge construction, offshore platforms, and industrial facilities. Their high strength-to-weight ratio makes them particularly valuable in projects where minimizing overall structure weight is crucial, such as in high-rise buildings or long-span bridges.

Standards For Structural Steel Pipes

To ensure consistency, safety, and quality in the production and use of structural steel pipes, various standards and specifications have been developed. These standards provide guidelines for manufacturing processes, material properties, testing procedures, and quality control measures. Some of the key standards include:

1. ASTM International Standards: The American Society for Testing and Materials (ASTM) provides several relevant standards, including:

- ASTM A500: Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes

- ASTM A53: Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

- ASTM A513: Standard Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing

2. API Standards: The American Petroleum Institute (API) provides standards particularly relevant for structural steel pipes used in oil and gas applications, such as API 5L for line pipes.

3. EN Standards: In Europe, the European Committee for Standardization (CEN) provides standards such as EN 10210 for hot-finished structural hollow sections and EN 10219 for cold-formed welded structural hollow sections.

4.ISO Standards: The World Organization for Standardization (ISO) produces worldwide norms that are frequently accepted or cited by national standards bodies.

When it comes to using structural steel pipes, they find applications in a wide range of projects. In building construction, they're often used for columns, beams, and trusses. In infrastructure projects, the products are employed in bridge construction, offshore platforms, and industrial facilities. Their high strength-to-weight ratio makes them particularly valuable in projects where minimizing overall structure weight is crucial, such as in high-rise buildings or long-span bridges.

Contact Longma Group

Structural steel pipe is a versatile and essential material in modern construction and engineering. Its combination of strength, adaptability, and cost-effectiveness makes it an ideal choice for a wide range of applications. By understanding what the product is, how to select and use it effectively, and the standards that govern its production, professionals can make informed decisions that lead to safer, more efficient, and more durable structures. Whether you're planning a small-scale project or a massive infrastructure development, considering structural steel pipe as a key component can provide significant benefits in terms of both performance and economics.

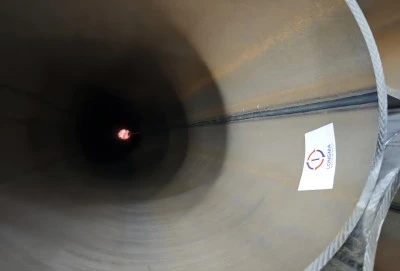

Corporations such as Longma Group specialize in creating large-diameter, thick-walled steel pipes that go above rigorous manufacturing requirements. With their expertise in manufacturing processes such as LSAW (Longitudinal Submerged Arc Welded) and ERW (Electric Resistance Welded) steel pipes, they offer solutions tailored to the most demanding structural applications. Welcome to contact us at info@longma-group.com.