In the world of steel pipes, two standards often come up in discussions: API 5L welded pipe and A53 pipe. While both are widely used in various industries, they have distinct characteristics that set them apart. This article will delve into the differences between these two types of pipes, exploring their standards, origins, materials, grades, and dimensional specifications. By understanding these distinctions, you'll be better equipped to choose the right pipe for your specific needs.

|

|

|

Standard and Origin

The primary difference between API 5L welded pipe and A53 pipe lies in their respective standards and origins. API 5L, which stands for American Petroleum Institute Specification 5L, is a standard specifically developed for the petroleum and natural gas industries. This specification covers seamless and welded steel line pipes used in pipeline transportation systems in the oil and gas sector.

On the other hand, A53 pipe falls under the ASTM (American Society for Testing and Materials) standard. ASTM A53 is a more general-purpose standard that covers both seamless and welded steel pipe for various applications, including mechanical and pressure applications in the construction industry.

The API 5L standard was first introduced in 1928 and has since undergone numerous revisions to keep up with technological advancements and industry requirements. It is recognized globally and is often the preferred choice for oil and gas pipelines due to its stringent quality control measures and specific focus on the petroleum industry's needs.

ASTM A53, while also widely used, has a broader scope. It was first published in 1915 and has been regularly updated to meet evolving industry standards. A53 pipes are commonly used in structural applications, fire protection systems, and general-purpose piping systems where the specialized requirements of API 5L may not be necessary.

It's worth noting that while API 5L welded pipes are primarily designed for oil and gas transportation, they can also be used in other applications where high-performance pipes are required. Conversely, A53 pipes, although more general-purpose, may sometimes be used in less demanding oil and gas applications.

Material and Grade

When it comes to materials and grades, both API 5L welded pipe and A53 pipe have their own classifications. API 5L pipes are typically made from carbon steel or low-alloy steel. The API 5L specification defines two product specification levels (PSL 1 and PSL 2), with PSL 2 having more stringent requirements for chemical composition, mechanical properties, and non-destructive examination.

API 5L grades are denoted by the letter "X" followed by a number indicating the minimum yield strength in ksi (thousand pounds per square inch). Common grades include X42, X52, X60, X70, and X80. For instance, an X70 grade pipe has a minimum yield strength of 70,000 psi. These higher-grade pipes are often used in high-pressure, high-temperature environments typical in oil and gas transportation.

A53 pipes, on the other hand, are available in three types: Type E (electric-resistance welded), Type F (furnace-butt welded, continuous welded), and Type S (seamless). They come in two grades: A and B. Grade B has higher mechanical requirements and is more commonly used than Grade A.

The chemical composition and mechanical properties of A53 pipes are generally less stringent than those of API 5L pipes. This is because A53 pipes are designed for a wider range of applications that may not require the same level of performance as oil and gas pipelines.

It's important to note that while API 5L welded pipes can often meet or exceed the requirements of A53 pipes, the reverse is not always true. API 5L pipes undergo more rigorous testing and quality control processes, particularly for higher grades and PSL 2 pipes.

Dimensional Specifications

The dimensional specifications of API 5L welded pipe and A53 pipe also differ, reflecting their intended applications and manufacturing processes. API 5L pipes are available in a wide range of sizes to accommodate various pipeline requirements in the oil and gas industry.

API 5L welded pipes typically range from 0.405 inches (10.3 mm) to 80 inches (2032 mm) in outside diameter. The wall thickness can vary significantly, from thin-walled pipes for low-pressure applications to thick-walled pipes for high-pressure environments. The length of API 5L pipes is often customizable to meet specific project requirements, with standard lengths ranging from 20 to 80 feet.

A53 pipes, being more general-purpose, have a somewhat more limited size range. They are commonly available in nominal pipe sizes (NPS) from 1/8 inch to 26 inches. The wall thickness is typically specified by schedule numbers, with Schedule 40 and Schedule 80 being the most common. A53 pipes are usually supplied in 21-foot random lengths, although other lengths can be specified.

Another key difference lies in the tolerances allowed for dimensional variations. API 5L specifications typically have tighter tolerances, especially for higher grades and PSL 2 pipes. This is crucial for ensuring proper fit and performance in critical oil and gas pipeline applications.

It's worth noting that while API 5L welded pipes often have more precise dimensional control, A53 pipes can be sufficient for many applications where such precision is not critical. The choice between the two often depends on the specific requirements of the project, including pressure ratings, temperature conditions, and regulatory compliance needs.

In conclusion, while API 5L welded pipe and A53 pipe may seem similar at first glance, they have significant differences in terms of their standards, materials, grades, and dimensional specifications. API 5L pipes are specifically designed for the demanding requirements of the oil and gas industry, with stringent quality control measures and a wide range of high-performance grades. A53 pipes, while more versatile, are generally used in less demanding applications where the specialized properties of API 5L pipes may not be necessary.

When choosing between API 5L welded pipe and A53 pipe, it's crucial to consider the specific requirements of your project. Factors such as operating pressure, temperature, environmental conditions, and regulatory requirements should all be taken into account. For high-pressure, high-temperature applications in the oil and gas industry, API 5L pipes are often the preferred choice due to their superior performance characteristics and stringent quality control.

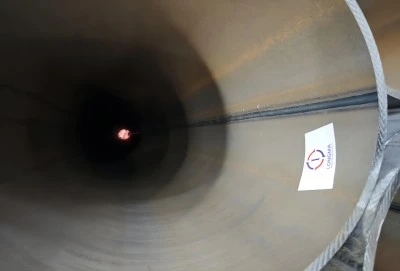

For those in need of high-quality API 5L welded pipes, Longma Group is a renowned manufacturer with a track record of excellence. Specializing in grades B, X42, X46, X52, X56, X60, X65, X70, and X80, Longma Group offers a range of welding types including ERW, LSAW, DSAW, and SSAW. With outer diameters ranging from 3" to 80" and thicknesses from SCH10 to SCH160, they can meet a wide variety of project requirements. Backed by API 5L, ISO, and QMS certifications, Longma Group is committed to providing excellent products and services. For more information or to discuss your specific needs, please contact them at info@longma-group.com.