When it comes to steel pipes and their various applications, understanding the differences between different standards is crucial. Two commonly encountered standards in the industry are ASTM A53 and ASTM A123. While both are related to steel products, they serve different purposes and have distinct characteristics. In this comprehensive guide, we'll explore the key differences between astm a53 steel pipe and ASTM A123, focusing on their materials, applications, and coating requirements.

|

|

|

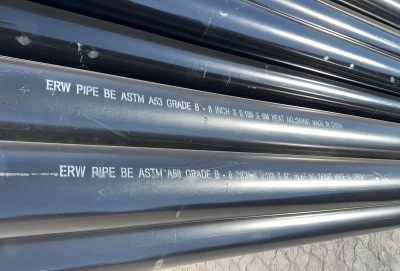

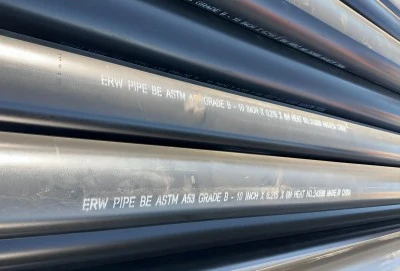

ASTM A53 Steel Pipe: Composition and Applications

ASTM A53 Steel Pipe is a widely used standard for steel pipe in various industries. This specification covers seamless and welded black and hot-dipped galvanized steel pipe for use in a range of applications. The ASTM A53 standard is particularly known for its versatility and reliability in different environments.

The composition of astm a53 steel pipe typically includes carbon steel with small amounts of manganese, phosphorus, sulfur, and other elements. This composition provides a balance of strength, ductility, and weldability, making it suitable for a wide range of applications. The standard covers pipes in nominal sizes from NPS 1/8 to NPS 26, offering flexibility for various project requirements.

ASTM A53 Steel Pipe finds applications in numerous industries, including:

- Oil and gas transmission

- Water and sewage systems

- Structural support in buildings

- Fire protection systems

- General-purpose piping for steam, water, air, and gas

One of the key advantages of ASTM A53 Steel Pipe is its ability to withstand high pressure and temperature, making it ideal for transporting fluids and gases in industrial settings. The standard also allows for different grades (A and B) and types (seamless, electric-resistance welded, and furnace-welded), providing options to meet specific project requirements.

It's worth noting that ASTM A53 Steel Pipe can be supplied with different end finishes, including plain end, threaded, or with couplings. This versatility in end treatments adds to its adaptability across various applications.

ASTM A123: Galvanization Standard for Fabricated Steel Products

While ASTM A53 is a standard for steel pipe, ASTM A123 is a specification for zinc (hot-dip galvanized) coatings on iron and steel products. This standard is not specific to pipes but applies to a wide range of fabricated steel products, including structural steel shapes, plates, bars, and more.

The primary purpose of ASTM A123 is to provide guidelines for the galvanization process, which involves coating steel or iron with a layer of zinc to protect against corrosion. This process significantly enhances the durability and longevity of steel products, particularly those exposed to harsh environmental conditions.

Key aspects of ASTM A123 include:

- Specifying the minimum coating thickness requirements based on material categories

- Outlining the galvanization process and quality control measures

- Providing guidelines for coating adhesion and finish

- Detailing inspection and testing procedures for galvanized products

The applications of ASTM A123 are vast, covering steel products used in:

- Bridge and highway construction

- Electrical transmission towers

- Industrial structures

- Marine environments

- Agricultural equipment

It's important to note that while astm a53 steel pipe can be galvanized, the galvanization process itself would typically follow the guidelines set forth in ASTM A123. This demonstrates how these two standards can work in conjunction to produce high-quality, corrosion-resistant steel products.

Comparing Coating Requirements: ASTM A53 vs. ASTM A123

When it comes to coating requirements, there are significant differences between ASTM A53 and ASTM A123. Understanding these differences is crucial for selecting the right product for specific applications and ensuring proper corrosion protection.

For ASTM A53 Steel Pipe:

- The standard allows for both black (uncoated) and hot-dip galvanized finishes.

- When galvanized, the coating weight is specified as a minimum of 1.8 oz/ft² (550 g/m²) of zinc coating.

- The galvanization is typically applied to the exterior surface of the pipe, with the interior either left uncoated or coated based on specific requirements.

- The standard does not provide detailed guidelines for the galvanization process itself.

In contrast, ASTM A123:

- It is specifically focused on the hot-dip galvanization process and its requirements.

- Provides detailed specifications for coating thickness based on the material's thickness and category.

- Requires galvanization of both interior and exterior surfaces for hollow sections.

- Specifies more rigorous testing and inspection procedures for the galvanized coating.

- Addresses issues such as coating adhesion, finish, and repair of galvanized coatings.

The coating requirements in ASTM A123 are generally more comprehensive and stringent than those in ASTM A53. This is because ASTM A123 is specifically designed to ensure high-quality galvanization across a wide range of steel products, whereas ASTM A53 is primarily focused on the pipe's structural and performance characteristics, with galvanization being an optional feature.

It's also worth noting that while astm a53 steel pipecan be galvanized to meet the requirements of ASTM A123, not all ASTM A53 pipes are necessarily galvanized to this standard. The choice often depends on the specific application and environmental conditions the pipe will face.

In some cases, particularly for severe corrosive environments, additional protective measures beyond standard galvanization may be necessary. This could include the use of protective paints or coatings applied over the galvanized surface, or the selection of alternative materials altogether.

Longma Group ASTM A53 Steel Pipe

In summary, while astm a53 steel pipe and ASTM A123 are both important standards in the steel industry, they serve different purposes. ASTM A53 is a comprehensive standard for steel pipe, covering its composition, manufacturing process, and performance requirements. ASTM A123, on the other hand, focuses specifically on the hot-dip galvanization process for a wide range of steel products, including but not limited to pipes.

Understanding these differences is crucial for selecting the right products for specific applications and ensuring proper corrosion protection. Whether you're working on a pipeline project, constructing a building, or developing infrastructure in a corrosive environment, knowing the nuances of these standards can help you make informed decisions and ensure the longevity and performance of your steel components.

Longma Group offers customization options for ASTM A53 ERW Pipe to meet the unique specifications and dimensions of individual projects, ensuring precise fit and functionality. If you are choosing your wholesale astm a53 erw steel pipe factories, welcome to contact LONGMA GROUP at info@longma-group.com.