Understanding the differences between various manufacturing processes is essential when selecting the right kind of pipe for your project. Electric resistance welded (ERW) pipes and seamless pipes are among the most widely used options on the market. It is essential to select the appropriate type based on your particular requirements because each type possesses its own distinct features, benefits, and applications.

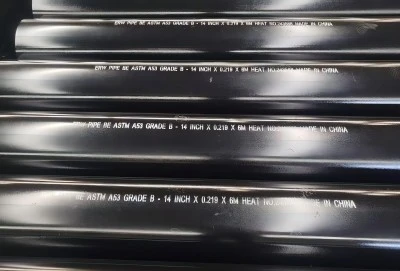

By rolling flat steel strips into a cylinder and welding the edges together with an electric current, electric resistance welded pipes are made. This method is often more cost-effective for larger quantities and makes production more effective. However, when compared to seamless pipes, ERW pipes may have limitations in terms of diameter and wall thickness.

In contrast, solid billets are extruded into cylinders to create seamless pipes, which have no welded seams and are continuous. The pipe's increased strength and uniformity as a result of this manufacturing process make them suitable for high-pressure applications.

|

|

|

Manufacturing Processes Of ERW and Seamless Pipes

Both electric resistance welded pipes have distinct characteristics due to the significant differences in their manufacturing processes.

Pipes that are electric resistance welded (ERW): From flat steel strips or coils, ERW pipes are made. After rolling the steel into a cylinder, the process involves heating the edges with high-frequency electrical current. After that, the heated edges are pressed together with a lot of force to form a forge weld that runs the length of the pipe. Because of how quickly this welding process works, the seam that comes out of it often looks like the rest of the pipe wall.

The highly automated electric resistance welded pipe manufacturing process can produce pipes quickly. ERW pipes are a popular choice for many applications due to their cost-effectiveness and efficiency.

Straight Pipes: The term "seamless" refers to pipes made without the use of welding. The manufacturing process begins with a round, solid steel billet that is heated to extremely high temperatures before being pierced or drawn across a mandrel to form a hollow form. After that, the hollow form is rolled and stretched until the desired diameter and wall thickness are achieved.

The consistent line creation process is more perplexing and tedious contrasted with ERW pipe producing. Be that as it may, it brings about a line with uniform strength all through its periphery, as there is no welded crease.

Comparative Analysis: Strength, Durability, and Applications

Both seamless pipe and electric resistance welded pipe have advantages and ideal applications. Let's compare them based on important aspects:

Strength and Tension Obstruction: Due to their uniform structure, seamless pipes are generally regarded as having superior strength and pressure resistance. Seamless pipes are ideal for high-pressure applications in industries like oil and gas, chemical processing, and power generation due to the absence of a welded seam.

Notwithstanding, current ERW pipes have altogether worked on in quality and strength. The weld seam in ERW pipes can be as strong as the base metal with advanced welding techniques, making them suitable for numerous high-pressure applications as well.

Resistance to Corrosion and Durability: Depending on the grade of steel used and any additional treatments applied, both ERW and seamless pipes can offer excellent durability and resistance to corrosion. Due to the absence of a weld seam, which could be a point of vulnerability, seamless pipes may have a slight advantage in extremely corrosive environments.

Size Class: ERW pipes typically come in sizes ranging from small to medium, typically up to 24 inches. Consistent lines, while regularly created in more modest widths, can be fabricated in bigger sizes for particular applications.

Applications: Electric resistance welded pipes are utilized extensively in numerous industrial processes, structural applications, and water transportation. They're especially well known in the development business because of their expense adequacy and dependable execution.

Consistent lines are many times picked for basic applications where most extreme strength and dependability are principal. Exploration of oil and gas, high-pressure boilers, and hydraulic systems are all common applications for them.

Cost Considerations: Which Pipe Type Offers Better Value?

Several factors come into play when comparing the cost-effectiveness of electric resistance welded pipe to seamless pipes:

Creation Expenses: For the most part, electric obstruction welded pipes are more affordable to deliver than consistent lines. Because it uses less energy and raw materials, the ERW manufacturing process is quicker and more effective. For end users, this cost advantage frequently results in lower prices.

Material Productivity: When compared to seamless pipes, ERW pipes typically have a wall thickness that is more consistent. This consistency makes it possible to use materials more precisely, which may result in less waste and save money.

Benefits Over Time: While consistent lines might have a higher forthright expense, they can offer better long haul esteem in specific high-stress or destructive conditions because of their uniform strength and potential for longer help life.

Costs specific to the application: The most practical decision relies upon the particular application. ERW pipes offer excellent performance at a lower cost for many common applications. However, the increased strength of seamless pipes may make up for the higher price in critical, high-pressure applications.

Contact Longma

In conclusion, seamless pipe and electric resistance welded pipe both have a place in various industries. electric resistance welded pipe offers a practical arrangement with great execution for some applications, while consistent lines give most extreme strength and unwavering quality to basic, high-pressure conditions. The choice you make between the two is contingent on the particular requirements of your project, such as pressure ratings, requirements for corrosion resistance, and financial constraints.

While choosing among ERW and consistent lines, it's vital to talk with specialists who can give direction in view of your particular requirements. Longma Group, which is a company that makes high-quality steel pipes like ERW and LSAW (Longitudinal Submerged Arc Welded) pipes, can give you valuable insights and project-specific solutions. you can get in touch with us at info@longma-group.com.

You can make an informed decision that ensures optimal performance and cost-effectiveness for your project by comprehending the differences between these pipe types and carefully considering the requirements of your application.