In the world of steel piping, two manufacturing processes stand out: Electric Resistance Welding (ERW) pipes and Cold-Drawn Welding (CDW). Both methods produce high-quality pipes, but they differ in their manufacturing processes, characteristics, and applications. This article will delve into the intricacies of ERW and CDW pipes, exploring their unique features and helping you understand which might be best suited for your specific needs.

|

|

|

What is electric resistance welded (ERW) steel pipe?

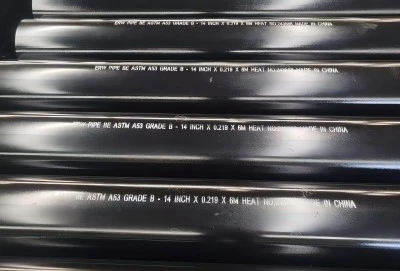

Electric resistance welded (ERW) steel pipe is a type of welded pipe manufactured through a unique process that utilizes electrical current to join the edges of rolled steel. The manufacturing process begins with a flat steel strip, which is gradually formed into a cylindrical shape. As the edges of the strip come together, a high-frequency electrical current is applied, generating heat at the point of contact. This heat, combined with pressure, creates a forge weld along the length of the pipe.

The ERW process is highly efficient and can produce pipes with diameters ranging from 8mm to 660mm (0.315 inches to 26 inches). One of the key advantages of ERW pipes is the speed of production, making them ideal for large-scale manufacturing. The welding process is continuous, allowing for the creation of long, uniform pipes with consistent quality.

ERW pipes are known for their smooth internal and external surfaces, which contribute to better flow characteristics and easier coating application. The welded seam, when properly executed, is nearly indistinguishable from the rest of the pipe, both in terms of appearance and strength.

What is cold-drawn welded (CDW) steel pipe?

Cold-drawn welded (CDW) steel pipe, also known as cold-drawn electric welded (CEW) pipe, is manufactured using a two-step process. The first step involves creating an electric welded tube, similar to the ERW process. However, the second step is what sets CDW pipes apart: the cold drawing process.

In cold drawing, the welded tube is pulled through a series of dies with progressively smaller diameters. This process is performed at room temperature, hence the term "cold-drawn." As the pipe is drawn through these dies, its diameter is reduced, and its wall thickness is increased. This results in a pipe with improved dimensional accuracy, surface finish, and mechanical properties .

The cold drawing process can be repeated multiple times to achieve the desired dimensions and properties. CDW pipes are known for their precise tolerances, excellent surface finish, and enhanced mechanical strength. They are commonly used in applications that require tight dimensional control and superior surface quality.

What are the strength and performance differences between ERW and CDW pipes?

While both ERW and CDW pipes are high-quality products, they exhibit different strengths and performance characteristics due to their distinct manufacturing processes:

1. Dimensional Accuracy: CDW pipes generally have superior dimensional accuracy compared to ERW pipes. The cold drawing process allows for tighter control over the pipe's diameter and wall thickness, making CDW pipes ideal for applications requiring precise fits.

2. Surface Finish: Both ERW and CDW pipes can have excellent surface finishes. However, CDW pipes often have a smoother surface due to the cold drawing process, which can be advantageous in applications where friction reduction is crucial.

3. Mechanical Properties: The cold drawing process in CDW pipe production increases the pipe's tensile strength and yield strength. This makes CDW pipes generally stronger than ERW pipes of the same material grade. However, this increased strength comes at the cost of some ductility.

4. Weld Seam: In ERW pipes, the weld seam is typically as strong as the base metal when properly executed. CDW pipes, having undergone the cold drawing process after welding, often have weld seams that are even less distinguishable from the base metal.

5. Size Range: ERW pipes are available in a wider range of sizes compared to CDW pipes. ERW pipes can be produced in diameters up to 660mm, while CDW pipes are typically limited to smaller diameters due to the limitations of the cold drawing process.

6. Production Efficiency: ERW pipes can be produced more quickly and in larger quantities, making them more cost-effective for large-scale projects. CDW pipes, due to the additional cold drawing step, have a longer production time and are often more expensive.

7. Applications: ERW pipes are widely used in oil and gas pipelines, structural applications, and general-purpose piping. CDW pipes, with their precise dimensions and smooth finish, are often preferred in automotive, hydraulic, and pneumatic systems where tight tolerances are critical.

It's important to note that the choice between ERW and CDW pipes depends on the specific requirements of your project. Factors such as required strength, dimensional accuracy, surface finish, and cost all play a role in determining which type of pipe is most suitable.

Contact Longma

Both electric resistance steel pipes and cold-drawn welded pipes have their unique strengths and ideal applications. ERW pipes offer cost-effective solutions for large-scale projects and a wide range of sizes, while CDW pipes excel in applications requiring precise dimensions and superior surface finish.

At Longma Group, we specialize in producing high-quality electric resistance welded steel pipes that meet the most stringent industry standards. Our ERW pipes are known for their consistency, reliability, and versatility across various applications. Whether you're working on an oil and gas pipeline, a structural project, or any other application requiring robust and efficient piping solutions, our team of experts is ready to assist you.

Don't let uncertainty about pipe selection hinder your project's success. Reach out to us today at info@longma-group.com to discuss your specific needs. Our knowledgeable staff will guide you through our product range, helping you select the perfect ERW steel pipe for your application. Let Longma Group be your partner in achieving project excellence with our top-tier pipes.