In the world of steel pipes, two common types often come up in discussions: Electric Resistance Welded (ERW) steel pipes and Drawn Over Mandrel (DOM) steel pipes. While both serve important roles in various industries, they have distinct differences in their manufacturing processes, properties, and applications. This article will delve into the key differences between ERW and DOM steel pipes, helping you understand which might be best suited for your specific needs.

|

|

|

How do ERW and DOM steel pipes differ in manufacturing?

The manufacturing processes for ERW and DOM steel pipes are fundamentally different, resulting in pipes with distinct characteristics.

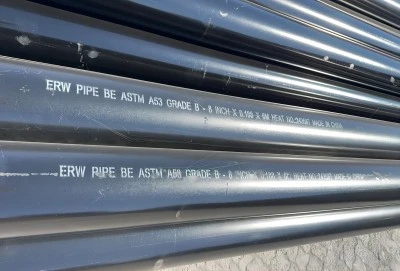

ERW Steel Pipe Manufacturing: Electric resistance welded steel pipe is produced using a continuous process. It starts with a flat steel strip that is gradually formed into a cylindrical shape. As the edges of the strip come together, they are welded using electric current, which generates heat through electrical resistance. This heat melts the edges, fusing them together to form a seam along the length of the pipe. The welding process is rapid and efficient, allowing for high-volume production.

Key steps in ERW pipe manufacturing include:

- Uncoiling and edge preparation of the steel strip

- Forming the strip into a cylindrical shape

- Welding the seam using electric resistance

- Removing excess material from the weld (if necessary)

- Heat treatment to relieve stress

- Sizing and straightening

- Inspection and testing

DOM Steel Pipe Manufacturing: DOM, or Drawn Over Mandrel, steel pipes undergo a more complex manufacturing process. It starts with an electric resistance welded tube, which then goes through additional steps to enhance its properties:

- The initial ERW tube is cold-drawn over a mandrel

- This process reduces the outer diameter and wall thickness

- The drawing process also improves the mechanical properties and surface finish

- Multiple drawing passes may be performed to achieve the desired dimensions and properties

- Heat treatment may be applied between passes to relieve stress

- Final sizing and straightening

- Inspection and testing

The DOM process results in a pipe with improved dimensional accuracy, surface finish, and mechanical properties compared to the original ERW pipe.

What are the mechanical properties of ERW vs. DOM pipes?

The distinct manufacturing processes of Electric Resistance Welded (ERW) and Drawn Over Mandrel (DOM) steel pipes lead to significant differences in their mechanical properties. While both types of pipes are widely used in various industries, their structural characteristics and performance make them suitable for different applications.

ERW Steel Pipes: Mechanical Properties

ERW pipes are produced by rolling a flat steel strip into a cylindrical shape and welding the seam using high-frequency electrical resistance. This process results in pipes with a consistent structure and uniform mechanical properties.

- Strength-to-Weight Ratio: ERW pipes offer a good balance of strength and weight, making them ideal for structural applications, water pipelines, and low-pressure fluid transportation.

- Wall Thickness Consistency: The automated manufacturing process ensures consistent wall thickness, which enhances predictability in mechanical performance.

- Uniform Mechanical Properties: ERW pipes generally exhibit consistent mechanical properties around the circumference, except in the weld seam area.

- Weld Seam Properties: The weld seam, although heat-treated and sometimes cold-worked for reinforcement, may still have slightly different properties compared to the base metal. This could result in minor variations in strength and ductility at the seam.

- Yield Strength: Typically ranges between 30,000 to 55,000 psi, depending on the steel grade and post-processing treatments.

- Tensile Strength: Usually falls between 45,000 to 65,000 psi, making ERW pipes suitable for medium-duty structural and mechanical applications.

DOM Steel Pipes:

- Higher strength-to-weight ratio compared to ERW pipes

- Improved dimensional accuracy and roundness

- Enhanced surface finish

- More uniform mechanical properties due to the cold-working process

- Higher yield strength, typically ranging from 55,000 to 85,000 psi

- Increased tensile strength, usually between 70,000 to 100,000 psi

- Better fatigue resistance

The cold-drawing process in DOM pipe manufacturing work-hardens the material, resulting in improved mechanical properties. This makes DOM pipes suitable for applications requiring higher strength and better fatigue resistance.

Which industries use ERW and DOM steel pipes?

Both ERW and DOM steel pipes find applications across various industries, but their specific properties make them more suitable for certain uses:

Industries Using ERW Steel Pipes:

- Oil and Gas: For transportation of oil, gas, and other fluids

- Construction: Structural support, scaffolding, and general construction

- Water Supply: Municipal water distribution systems

- Agriculture: Irrigation systems and fencing

- Automotive: Exhaust systems and structural components

- Furniture: Metal furniture frames and supports

ERW pipes are often chosen for their cost-effectiveness and suitability for high-volume production. They perform well in applications where moderate strength and good weldability are required.

Industries Using DOM Steel Pipes:

- Aerospace: Hydraulic and pneumatic systems

- Automotive: Steering columns, drive shafts, and other precision components

- Manufacturing: Cylinders for hydraulic and pneumatic equipment

- Construction Equipment: Hydraulic systems in heavy machinery

- Medical Equipment: Precision components in medical devices

- Fitness Equipment: Weight-bearing structures in exercise machines

DOM pipes are preferred in applications requiring higher strength, better surface finish, and tighter tolerances. Their improved fatigue resistance makes them ideal for components subjected to cyclic loading.

In conclusion, while both electric resistance welded steel pipe and DOM steel pipe serve essential roles in various industries, they have distinct characteristics that make them suitable for different applications. ERW pipes offer cost-effective solutions for many general-purpose applications, while DOM pipes excel in high-precision, high-strength scenarios.

If you're in need of high-quality electric resistance welded steel pipes for your project, look no further than Longma Group. With our state-of-the-art manufacturing facilities and commitment to quality, we can provide ERW pipes that meet your exact specifications. Don't let subpar products derail your projects. Reach out to our team of experts today at info@longma-group.com to discuss your needs and get a customized solution. Your successful projects await with Longma Group's premium ERW steel pipes!