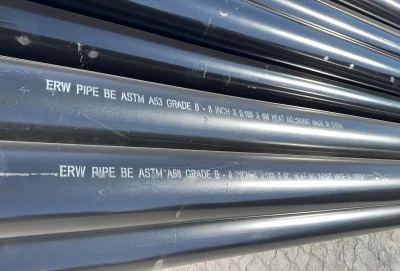

ERW pipe and normal pipe differ significantly in their manufacturing processes, strength, and applications. ERW (Electric Resistance Welded) pipes, including ERW black pipes, are formed using high-frequency electric resistance welding, resulting in a strong, uniform seam. Normal pipes, often referred to as seamless pipes, are produced without welding. This fundamental difference affects their performance in various industrial settings, particularly in oil and gas transportation, water supply systems, and offshore platform construction.

|

|

|

Manufacturing Process: ERW vs. Traditional Pipe Production

Electric Resistance Welding: ERW Pipe FormationERW black pipe production is a modern, efficient process that begins with flat steel strips. These strips are carefully rolled into a cylindrical shape and then welded along the seam using high-frequency electrical currents. This method creates a strong, consistent weld that's often indistinguishable from the base metal.

The ERW process allows for precise control over pipe dimensions and wall thickness, making it ideal for producing pipes with tight tolerances. This precision is crucial in industries like oil and gas, where exact specifications are essential for safety and performance.

Seamless Pipe Production: Traditional Method

Seamless pipes, the most common type of "normal" pipes, are manufactured using a different approach. The process starts with a solid steel billet that's heated and pierced to create a hollow tube. This tube is then rolled and stretched to achieve the desired diameter and wall thickness.

While seamless pipes offer excellent uniformity in wall thickness, they can be more expensive to produce and may have limitations in terms of length and diameter compared to ERW pipes.

Quality Control: ERW vs. Normal Pipe Manufacturing

Quality control is paramount in both ERW and seamless pipe production. ERW pipes undergo rigorous testing, including ultrasonic inspection of the weld seam, to ensure integrity. Seamless pipes are typically subjected to hydrostatic testing and various non-destructive examinations.

ERW pipes often have an advantage in terms of consistency due to the controlled welding process. However, both types can meet stringent industry standards when manufactured correctly.

Strength and Durability: ERW Pipe Advantages

High-Frequency Welding: Enhanced Joint StrengthThe high-frequency welding used in ERW pipe production creates a bond that's often as strong as or stronger than the base metal. This results in a pipe with uniform strength along its entire length, including the welded seam.

For applications requiring high pressure resistance, such as in oil and gas pipelines, ERW pipes can offer excellent performance. The welding process also allows for better control over the pipe's metallurgical properties, enhancing its overall strength.

Corrosion Resistance: ERW Pipe Performance

ERW pipes, particularly ERW black pipes, can exhibit good corrosion resistance when properly manufactured and treated. The welding process can be optimized to minimize heat-affected zones, which are often more susceptible to corrosion.

In comparison, seamless pipes may have a slight edge in corrosion resistance due to their uniform structure. However, with proper coating and treatment, ERW pipes can match or exceed the corrosion resistance of seamless pipes in many applications.

Pressure Capacity: ERW vs. Seamless Pipes

Both ERW black pipe and seamless pipes can handle high-pressure applications, but their performance can vary depending on specific requirements. ERW pipes often excel in consistent pressure distribution due to their uniform wall thickness and weld strength.

Seamless pipes are traditionally preferred for extremely high-pressure applications, but advancements in ERW technology have narrowed this gap. Many industries now use ERW pipes for high-pressure systems, recognizing their reliability and cost-effectiveness.

Cost-Effectiveness: Why Industries Choose ERW Pipes

Production Efficiency: ERW Pipe Manufacturing SpeedERW black pipe production is generally faster and more efficient than seamless pipe manufacturing. The continuous welding process allows for higher production rates, reducing overall manufacturing time and costs.

This efficiency translates to quicker project completion times, which is crucial for large-scale engineering projects in the oil and gas sector or water supply system installations. Faster production also means ERW pipes can be more readily available when needed for urgent projects or repairs.

Material Utilization: ERW Pipe Cost Benefits

ERW black pipe production typically results in less material waste compared to seamless pipe manufacturing. The steel strip used in ERW pipes can be precisely cut to size, minimizing excess material.

This efficient material utilization contributes to lower production costs, making ERW pipes a more economical choice for many applications. The cost savings can be significant, especially for large-scale projects requiring extensive piping systems.

Versatility: ERW Pipes in Various Applications

ERW pipes, including ERW black pipes, find use in a wide range of industries due to their versatility. They're commonly used in oil and gas transportation, water supply systems, and structural applications in bridge and building construction.

The ability to produce ERW pipes in various sizes and grades allows them to meet diverse project requirements. This versatility, combined with their cost-effectiveness, makes ERW pipes an attractive option for many industrial applications.

ERW pipes and normal pipes each have their strengths, but ERW pipes often stand out in terms of manufacturing efficiency, cost-effectiveness, and versatility. While seamless pipes remain crucial for certain high-pressure applications, advancements in ERW technology have expanded their use across various industries. For project managers and engineers in sectors like oil and gas, water supply, and construction, understanding these differences is key to making informed decisions about pipe selection. As technology continues to evolve, ERW pipes, including specialized variants like ERW black pipes, are likely to play an increasingly important role in global infrastructure projects.

Where to Buy ERW Black Pipes?

For expert guidance, Hebei Longma Group is a leading choice. With advanced production equipment imported from Germany and independently developed technologies, they ensure top-notch quality. Their professional team of over 300 employees, including 60+ technical experts, guarantees precision and innovation. Comprehensive testing facilities, including ultrasonic flaw detectors and X-ray equipment, ensure product integrity. Hebei Longma Group offers fast delivery. They hold complete certifications, including API 5L and ISO 9001, meeting global standards. Thanks to stable raw material partnerships and efficient production, they offer competitive pricing without compromising quality. For ERW black pipes that meet your project's demands, contact us at info@longma-group.com.