In the world of steel pipe manufacturing, API 5L welded pipes are widely used in various industries, particularly in oil and gas transportation. Two popular grades within this specification are Grade B and X42. While both are part of the API 5L standard, they have distinct characteristics that make them suitable for different applications. This article will explore the key differences between API 5L Grade B welded pipe and X42 pipe, focusing on their material grade and strength, manufacturing and testing processes, and certification and standards.

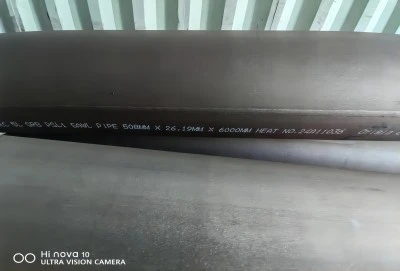

|

|

|

Material Grade and Strength

The primary difference between API 5L Grade B welded pipe and X42 pipe lies in their material composition and strength properties. Both grades are part of the API 5L specification, which is a standard for line pipe used in oil and gas transportation systems. However, they are designed to meet different performance requirements.

API 5L Grade B welded pipe is considered a standard grade within the API 5L specification. It has a minimum yield strength of 35,000 psi (241 MPa) and a minimum tensile strength of 60,000 psi (414 MPa). Grade B pipes are commonly used in applications where moderate strength is sufficient, such as low-pressure oil and gas pipelines, water transportation, and general construction.

On the other hand, X42 pipe belongs to the high-strength low-alloy (HSLA) category within the API 5L specification. The "X" in X42 denotes that it is a higher-grade material, while the number "42" represents its minimum yield strength in ksi (thousand pounds per square inch). X42 pipe has a minimum yield strength of 42,000 psi (290 MPa) and a minimum tensile strength of 60,000 psi (414 MPa). This higher yield strength makes X42 pipes suitable for applications requiring greater pressure resistance and structural integrity, such as high-pressure oil and gas pipelines.

The chemical composition of these two grades also differs slightly. X42 pipe typically contains a higher percentage of alloying elements like manganese, which contributes to its increased strength. This composition allows X42 pipes to maintain their mechanical properties even in more demanding environments.

It's worth noting that while X42 pipe offers higher strength, Grade B pipe may be more cost-effective for applications that don't require the additional strength. The choice between the two often depends on specific project requirements, operating conditions, and budget considerations.

Manufacturing and Testing

The manufacturing processes for API 5L Grade B welded pipe and X42 pipe share many similarities, as both fall under the API 5L welded pipe category. However, there are some differences in the manufacturing techniques and quality control measures employed to achieve their respective properties.

Both Grade B and X42 pipes can be manufactured using various welding methods, including Electric Resistance Welding (ERW), Longitudinal Submerged Arc Welding (LSAW), and Spiral Submerged Arc Welding (SSAW). The choice of welding method often depends on factors such as pipe diameter, wall thickness, and intended application.

For Grade B pipes, the manufacturing process typically involves forming steel plates or coils into a cylindrical shape and then welding the seam. The welding process is carefully controlled to ensure proper fusion and minimal defects. After welding, the pipes undergo heat treatment to relieve stress and achieve the desired mechanical properties.

X42 pipes, due to their higher strength requirements, may undergo additional processing steps. This can include more precise control of the steel chemistry during production and specialized heat treatment processes to achieve the required strength and toughness. The welding process for X42 pipes may also involve more stringent controls to ensure the weld seam meets the higher strength requirements.

Testing procedures for both grades are rigorous and comply with API 5L specifications. However, X42 pipes may undergo additional testing to verify their higher strength properties. Common tests for both grades include:

- Tensile testing to measure yield strength and tensile strength

- Charpy V-notch impact testing to assess toughness

- Hydrostatic testing to check for leaks and pressure resistance

- Non-destructive testing methods such as ultrasonic testing or radiographic testing to detect any defects in the pipe body or weld seam

X42 pipes may be subject to more frequent or extensive testing to ensure they consistently meet the higher strength requirements. This can include additional mechanical tests and more rigorous inspection of the weld seam integrity.

It's important to note that while the manufacturing processes for Grade B and X42 pipes are similar, the quality control measures and testing procedures are tailored to ensure each grade meets its specific performance criteria.

Certification and Standards

Both API 5L Grade B welded pipe and X42 pipe are manufactured and certified according to the American Petroleum Institute's API 5L specification. This specification sets the standards for line pipe used in oil and gas transportation systems. However, there are some differences in the certification requirements and additional standards that may apply to each grade.

API 5L Grade B welded pipe is certified to meet the basic requirements of the API 5L specification. This certification ensures that the pipe meets the minimum standards for chemical composition, mechanical properties, and dimensional tolerances. Grade B pipes are widely accepted for use in various industries and are often sufficient for many standard pipeline applications.

X42 pipe, being a higher-grade material, must meet more stringent certification requirements. In addition to the basic API 5L certification, X42 pipes may need to comply with supplementary requirements specified by the purchaser or end-user. These additional requirements can include:

- Enhanced toughness properties

- Stricter tolerances on chemical composition

- More comprehensive non-destructive testing

- Specific heat treatment processes

Furthermore, X42 pipes may need to meet additional industry standards depending on their intended application. For instance, if used in offshore oil and gas projects, they might need to comply with standards set by organizations such as DNV GL (Det Norske Veritas Germanischer Lloyd) or ABS (American Bureau of Shipping).

Both Grade B and X42 pipes can be certified to international standards such as ISO 3183, which is harmonized with API 5L. This allows for global recognition and acceptance of these pipe grades in various markets.

It's worth noting that certification for both grades involves thorough documentation of the manufacturing process, material properties, and test results. This documentation is crucial for ensuring traceability and quality assurance throughout the supply chain.

When selecting between API 5L Grade B welded pipe and X42 pipe, it's essential to consider not only the basic certification but also any additional standards or requirements specific to the project or application. Consulting with experienced manufacturers and engineers can help ensure that the chosen pipe grade meets all necessary certifications and standards for its intended use.

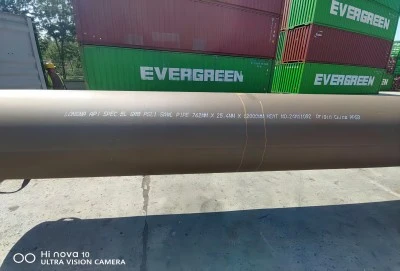

API 5L Welded Pipes Manufacturer

In conclusion, while both API 5L Grade B welded pipe and X42 pipe fall under the API 5L specification, they have distinct characteristics that make them suitable for different applications. Grade B pipes offer standard strength and are cost-effective for many general applications, while X42 pipes provide higher strength for more demanding environments.

The choice between these two grades depends on factors such as required strength, operating pressure, environmental conditions, and project budget. Both grades undergo rigorous manufacturing and testing processes, but X42 pipes may be subject to more stringent quality control measures due to their higher performance requirements.

When selecting API 5L pipes for your project, it's crucial to consider all aspects, including material properties, manufacturing processes, and applicable standards. For expert guidance and high-quality welded pipes, consider reaching out to Longma Group. As a leading API 5L welded pipes manufacturer, including grades B, X42, and higher, Longma Group offers a wide range of options to meet your specific needs. With an annual output exceeding 1,000,000 tons and a commitment to excellence, Longma Group is well-equipped to provide top-notch products and services for your pipeline projects. For more information or to discuss your requirements, please email info@longma-group.com. Their team of experts is ready to assist you in selecting the right pipe for your application, ensuring optimal performance and reliability.