When it comes to steel pipes used in the oil and gas industry, API 5L Grade B is a widely recognized and utilized specification. One crucial property of these pipes is their hardness, which plays a significant role in their performance and applications. In this comprehensive guide, we'll explore the hardness of API 5L Grade B pipes, discuss estimated hardness ranges, examine factors affecting hardness, and delve into situations where hardness becomes a critical consideration.

|

|

|

Estimated Hardness Ranges for API 5L Grade B

API 5L Grade B is a standard specification for line pipe used in oil and gas transportation. While the API 5L specification does not explicitly state a required hardness value for Grade B, it's essential to understand the typical hardness ranges associated with this grade.

Generally, API 5L Grade B pipes exhibit a hardness range of approximately 137-187 HBW (Brinell Hardness). This range corresponds to roughly 75-90 HRB (Rockwell B Hardness). It's important to note that these values are estimates and can vary depending on various factors, including the manufacturing process, heat treatment, and chemical composition of the steel.

The hardness of API 5L Grade B pipes is closely related to their tensile strength. According to the API 5L specification, Grade B pipes should have a minimum yield strength of 35,000 psi (241 MPa) and a minimum tensile strength of 60,000 psi (414 MPa). These strength requirements indirectly influence the hardness of the material.

It's worth mentioning that while hardness is an important property, it's not the sole determining factor in the performance of API 5L welded pipe. Other characteristics such as ductility, toughness, and corrosion resistance also play crucial roles in the overall performance of the pipe in various applications.

Factors Affecting Hardness of API 5L Grade B Pipes

Several factors can influence the hardness of API 5L Grade B pipes. Understanding these factors is crucial for both manufacturers and end-users to ensure the pipes meet the required specifications and perform optimally in their intended applications.

- Chemical Composition: The chemical makeup of the steel used in API 5L Grade B pipes significantly affects their hardness. Elements such as carbon, manganese, and silicon contribute to the steel's strength and hardness. The API 5L specification provides limits for these elements to ensure consistent properties across different manufacturers.

- Manufacturing Process: The method used to produce the pipe can impact its hardness. For instance, seamless pipes may have different hardness characteristics compared to welded pipes due to variations in the manufacturing process. In the case of API 5L welded pipe, the welding method and subsequent heat treatment can influence the hardness, particularly in the heat-affected zone (HAZ) around the weld.

- Heat Treatment: Various heat treatment processes, such as normalizing, quenching, and tempering, can be applied to adjust the hardness and other mechanical properties of the steel. The specific heat treatment used can significantly affect the final hardness of the pipe.

- Cold Working: Any cold working during the manufacturing process, such as cold expansion or cold drawing, can increase the hardness of the steel due to work hardening.

- Pipe Diameter and Wall Thickness: The dimensions of the pipe can indirectly affect its hardness. Larger diameter pipes or those with thicker walls may cool at different rates during manufacturing, potentially leading to variations in hardness across the pipe's cross-section.

- Microstructure: The microstructure of the steel, which is influenced by factors such as cooling rate and alloying elements, plays a crucial role in determining the hardness of the pipe.

It's important to note that while these factors can affect hardness, reputable manufacturers of API 5L welded pipe carefully control their processes to ensure consistent properties that meet or exceed the API 5L specification requirements.

When Hardness Matters in API 5L Grade B Pipes?

While hardness is an important property of API 5L Grade B pipes, its significance can vary depending on the specific application and operating conditions. Let's explore some scenarios where hardness becomes a critical consideration:

- Wear Resistance: In applications where the pipe is subject to abrasive materials or frequent mechanical contact, higher hardness can contribute to better wear resistance. This is particularly important in pipelines transporting slurries or in situations where pigging operations are frequent.

- Corrosion Resistance: While hardness itself doesn't directly correlate with corrosion resistance, it can influence the pipe's susceptibility to certain types of corrosion. For instance, harder steels may be more resistant to erosion-corrosion in high-flow environments.

- Hydrogen-Induced Cracking (HIC): In sour service applications where hydrogen sulfide is present, the hardness of the pipe becomes crucial. Harder steels are generally more susceptible to HIC, so maintaining hardness within an acceptable range is vital for these applications.

- Welding Considerations: The hardness of the base metal can affect the weldability of the pipe. Excessively hard materials may be more challenging to weld and could require special welding procedures or post-weld heat treatment.

- Ductility and Toughness: While not directly related, hardness often inversely correlates with ductility and toughness. In applications where the pipe may be subject to impact loads or require a certain degree of flexibility, balancing hardness with these other properties becomes crucial.

- Cold Temperature Service: For pipelines operating in cold environments, the relationship between hardness and low-temperature toughness becomes important. Excessively hard materials may become brittle at low temperatures, increasing the risk of failure.

- Regulatory Compliance: Some industry standards or project specifications may include hardness requirements or limitations, particularly for sour service or other specialized applications.

It's worth noting that while API 5L Grade B is a widely used specification, some projects may require additional hardness testing or have specific hardness requirements beyond the standard API 5L specification. In such cases, customers may work closely with manufacturers of API 5L welded pipe to ensure the pipes meet these additional criteria.

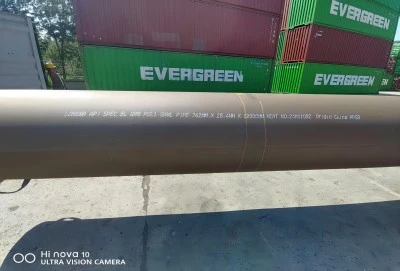

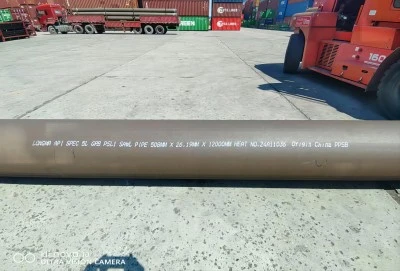

About Longma Group

Understanding the hardness of API 5L B pipes is crucial for ensuring their suitability for various applications in the oil and gas industry. While the typical hardness range for these pipes is approximately 137-187 HBW, it's important to remember that hardness is just one of many properties that contribute to the overall performance of the pipe.

Factors such as chemical composition, manufacturing processes, and heat treatment can all influence the hardness of API 5L Grade B pipes. The significance of hardness becomes particularly apparent in applications involving wear resistance, corrosion considerations, welding, and operation in extreme environments.

For those seeking high-quality API 5L welded pipe that meets stringent industry standards, Longma Group stands out as a reliable manufacturer. With expertise in producing a wide range of API 5L grades, including Grade B, X42, X46, X52, X56, X60, X65, X70, and X80, Longma Group offers various welding types such as ERW, LSAW, DSAW, and SSAW. Their pipes are available in outer diameters from 3" to 80" and thicknesses from SCH10 to SCH160. Backed by API 5L, ISO, and QMS certifications, Longma Group is committed to delivering excellent products and services. For more information or to discuss your specific pipe requirements, please don't hesitate to contact Longma Group at info@longma-group.com.