The pressure rating of welded steel pipe refers to the maximum internal pressure it can safely withstand during operation. This crucial parameter is typically measured in pounds per square inch (PSI) and varies depending on factors such as pipe diameter, wall thickness, material grade, and manufacturing process. Welded pipes are engineered to handle a wide range of pressure ratings, from low-pressure applications around 150 PSI to high-pressure systems exceeding 10,000 PSI. Understanding these ratings is essential for selecting the right pipe for specific project requirements in industries like oil and gas, water supply, and industrial manufacturing.

|

|

|

Understanding PSI: The Key to Pipe Strength

Defining PSI in welded steel pipe applications

PSI, or pounds per square inch, is the standard unit used to measure pressure in welded steel pipe applications. It represents the force exerted per unit area within the pipe. For engineers and project managers working in pipeline construction or industrial facilities, grasping the concept of PSI is crucial for ensuring system safety and efficiency.

In the context of welded steel pipes, PSI ratings indicate the maximum internal pressure a pipe can handle before risking structural failure. These ratings are determined through rigorous testing and calculations based on pipe specifications and industry standards. For example, a pipe rated at 1,500 PSI can safely contain fluids or gases exerting up to 1,500 pounds of force per square inch on its inner walls.

How PSI affects pipe performance and durability

The PSI rating directly impacts a welded steel pipe's performance and longevity. Higher PSI ratings generally indicate greater strength and durability, allowing pipes to withstand more demanding operating conditions. This is particularly important in high-pressure environments like deep-sea oil extraction or long-distance gas transportation.

Pipes operating at or near their maximum PSI rating may experience increased stress, potentially leading to fatigue or premature failure if not properly managed. Conversely, using pipes with PSI ratings significantly higher than required can result in unnecessary costs. Striking the right balance is key to optimizing both safety and cost-effectiveness in pipeline projects.

Common PSI ratings for different pipe sizes

Welded steel pipes that come in a variety of sizes and corresponding PSI ratings to suit different applications. Here are some common examples:

- Small diameter pipes (1/2" to 2"): Often rated between 700-2,000 PSI for standard wall thicknesses.

- Medium diameter pipes (3" to 12"): Typically range from 400-1,500 PSI depending on wall thickness and grade.

- Large diameter pipes (14" and above): Can vary widely, from 300 PSI for water transmission to over 2,500 PSI for high-pressure oil and gas lines.

It's important to note that these are general ranges, and specific PSI ratings can differ based on manufacturing processes, material grades, and intended applications. Always consult project specifications and relevant industry standards when selecting pipes for your projects.

Factors Affecting Welded Pipe Pressure Capacity

Wall thickness and its impact on pressure ratingsWall thickness is a critical factor in determining the pressure capacity of welded steel pipes. Generally, pipes with thicker walls can withstand higher internal pressures. This relationship is governed by the hoop stress formula, which calculates the circumferential stress in a cylindrical pressure vessel.

For example, a 12-inch diameter pipe with a 0.375-inch wall thickness might have a pressure rating of 1,000 PSI, while the same diameter pipe with a 0.500-inch wall could be rated for 1,500 PSI or more. However, increasing wall thickness also adds weight and cost to the pipe, so engineers must balance pressure requirements with practical considerations.

Material grade: Choosing the right steel for pressure

The grade of steel used in pipe manufacturing significantly influences its pressure-bearing capacity. Higher-grade steels, with increased yield strength and tensile strength, allow for higher pressure ratings without necessitating thicker walls. Common grades for welded steel pipes include:

- API 5L X42 to X70: Used in oil and gas pipelines, with increasing strength as the grade number rises.

- ASTM A53 Grade B: A versatile grade suitable for many industrial applications.

- API 5L X80 and above: High-strength grades for demanding, high-pressure applications.

Selecting the appropriate grade involves considering not only pressure requirements but also factors like temperature, corrosion resistance, and weldability.

Welding quality and its role in pressure resistance

The integrity of the weld seam is paramount in ensuring that a welded steel pipe can withstand its rated pressure. Poor welding can create weak points susceptible to failure under pressure. Key aspects of welding quality include:

- Weld penetration: Ensuring the weld extends through the full thickness of the pipe wall.

- Consistency: Maintaining uniform weld quality along the entire length of the pipe.

- Defect minimization: Reducing issues like porosity, inclusions, or lack of fusion.

Advanced welding techniques, such as submerged arc welding (SAW) for large diameter pipes or high-frequency welding for smaller diameters, help achieve the necessary weld quality for high-pressure applications. Regular inspection and testing, including hydrostatic pressure tests and non-destructive examinations, are essential to verify weld integrity and overall pipe pressure resistance.

Choosing the Right Pipe: Pressure vs. Application

Matching pipe pressure ratings to industry standardsSelecting the appropriate welded steel pipe for a project requires aligning pressure ratings with industry-specific standards and regulations. Different sectors have unique requirements:

- Oil and Gas: Pipes must comply with API 5L specifications, which define pressure ratings based on pipe grade and dimensions.

- Water Supply: AWWA standards govern pressure ratings for municipal and industrial water systems.

- Building Structures: ASTM standards provide guidelines for structural applications, including allowable stresses.

Engineers must consider safety factors when selecting pipes, typically choosing ratings 1.5 to 2 times higher than the maximum expected operating pressure. This ensures a margin of safety for unexpected pressure surges or long-term stress.

High-pressure applications: LSAW vs ERW pipe options

For high-pressure applications, two main types of welded steel pipes are commonly considered:

- LSAW (Longitudinal Submerged Arc Welded) Pipes: Ideal for large diameter, high-pressure lines. They offer superior strength and can be manufactured with thicker walls, making them suitable for offshore platforms and deep-sea pipelines.

- ERW (Electric Resistance Welded) Pipes: More cost-effective for smaller diameters and moderate pressures. Modern HFW (High-Frequency Welded) pipes, a type of ERW, can handle higher pressures than traditional ERW pipes.

The choice between LSAW and ERW depends on specific project requirements, including pressure ratings, diameter needs, and budget constraints. LSAW pipes generally offer higher pressure capacities but come at a premium price compared to ERW options.

Cost-effective solutions for low-pressure systems

For low-pressure applications, such as water distribution or some industrial processes, cost-effectiveness becomes a primary consideration. Strategies to optimize pipe selection for these systems include:

- Utilizing thinner-walled pipes: Lower pressure requirements allow for reduced wall thickness, saving on material costs.

- Opting for lower grade steels: When high strength isn't necessary, more economical steel grades can suffice.

- Considering alternative materials: In some low-pressure scenarios, materials like PVC or HDPE might be viable alternatives to steel.

However, it's crucial to consider factors beyond just pressure, such as corrosion resistance, temperature requirements, and expected service life. A holistic approach to pipe selection ensures optimal performance and long-term cost-effectiveness, even in low-pressure systems.

Understanding the pressure rating of welded steel pipes is crucial for ensuring the safety, efficiency, and longevity of pipeline systems across various industries. From oil and gas transportation to water supply networks, the right pipe selection can make or break a project's success. By considering factors such as wall thickness, material grade, and welding quality, engineers and project managers can make informed decisions that balance performance requirements with cost-effectiveness. As technology advances and industry standards evolve, staying updated on the latest developments in welded steel pipe manufacturing and testing is essential for professionals in the field.

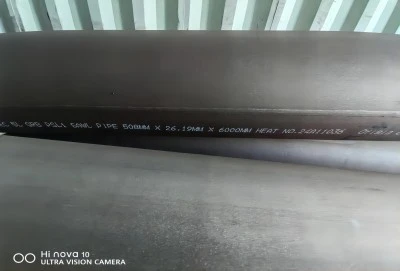

Welded Steel Pipe For Sale

Hebei Longma Group offers high-quality welded pipes tailored to meet diverse industry needs. Our state-of-the-art production facilities, featuring equipment imported from Germany and four independently developed production lines, ensure superior product quality. With a team of over 300 employees, including 60+ technical experts, we bring extensive expertise to every project. Our comprehensive testing facilities, including ultrasonic flaw detectors and X-ray equipment, guarantee the integrity of our pipes. We pride ourselves on fast delivery, with standard thickness pipes ready in as little as 7 days. Our products are backed by numerous certifications, including API 5L, ISO 9001, and ISO 14001. Thanks to our efficient production model and strong supplier relationships, we offer competitive pricing without compromising on quality. For more information on our welded steel pipe offerings, contact us at info@longma-group.com.