In the world of steel pipe manufacturing, quality and adherence to international standards are paramount. Among the various types of steel pipes, API 5L welded pipes stand out for their widespread use in oil and gas pipelines. But what exactly are the standards that govern these crucial components of our energy infrastructure? This comprehensive guide will delve into the intricacies of welded pipe standards, with a particular focus on API 5L certification, ISO certification, and Quality Management System (QMS) certification.

|

|

|

The Importance of API 5L Certification for Welded Pipes

API 5L, which stands for American Petroleum Institute Specification 5L, is the gold standard for line pipe used in oil and gas transportation. This specification covers seamless and welded steel line pipes, including the popular API 5L welded pipe. The API 5L standard is crucial because it ensures that pipes meet specific requirements for chemical composition, mechanical properties, and dimensions.

For manufacturers of API 5L welded pipes, compliance with this standard means adhering to strict guidelines on:

- Manufacturing processes

- Material quality

- Dimensional tolerances

- Hydrostatic testing

- Non-destructive examination

API 5L welded pipes are categorized into various grades, such as Grade B, X42, X52, X60, and up to X80, each with specific strength requirements. The higher the grade number, the greater the yield strength of the pipe. This grading system allows engineers to select the most appropriate pipe for their specific project needs, considering factors like operating pressure and environmental conditions.

Moreover, API 5L certification isn't just about the end product. It encompasses the entire manufacturing process, from raw material selection to final inspection. This comprehensive approach ensures that every API 5L welded pipe leaving the factory meets the rigorous standards set by the American Petroleum Institute.

For companies in the oil and gas sector, using API 5L certified welded pipes is often a non-negotiable requirement. It provides assurance of quality, reliability, and safety – critical factors when dealing with the transportation of volatile substances over long distances and under varying conditions.

ISO Certification: Ensuring Global Quality Standards

While API 5L certification is specific to line pipes, ISO (International Organization for Standardization) certification provides a broader framework for quality management across various industries. For welded pipe manufacturers, ISO certification, particularly ISO 9001, is a testament to their commitment to quality management principles.

ISO 9001 is the international standard that specifies requirements for a quality management system (QMS). For manufacturers of API 5L welded pipes, ISO 9001 certification demonstrates their ability to consistently provide products that meet customer and regulatory requirements.

Key aspects of ISO 9001 certification include:

- Customer focus

- Leadership commitment

- Process approach

- Continuous improvement

- Evidence-based decision making

For welded pipe manufacturers, ISO certification often goes hand in hand with API 5L certification. While API 5L focuses on the specific requirements for line pipes, ISO 9001 ensures that the overall quality management system of the company is robust and effective.

Additionally, there are other ISO standards relevant to the steel pipe industry. For instance, ISO 3183 is specific to petroleum and natural gas industries – steel pipe for pipeline transportation systems. This standard is often used in conjunction with API 5L, providing a comprehensive framework for quality assurance in pipeline manufacturing.

The global recognition of ISO certification makes it particularly valuable for manufacturers looking to operate in international markets. It provides customers worldwide with the confidence that the welded pipes they're purchasing meet consistent quality standards, regardless of where they were manufactured.

QMS Certification: The Backbone of Quality Assurance

Quality Management System (QMS) certification is a crucial aspect of modern manufacturing, especially in industries where precision and reliability are non-negotiable, such as in the production of API 5L welded pipes. A QMS is a formalized system that documents processes, procedures, and responsibilities for achieving quality policies and objectives.

For welded pipe manufacturers, a robust QMS ensures:

- Consistency in product quality

- Efficient use of resources

- Effective risk management

- Improved customer satisfaction

- Compliance with regulatory requirements

QMS certification, often based on ISO 9001 standards, involves a third-party audit of a company's quality management processes. This certification provides tangible evidence that the manufacturer has implemented a systematic approach to quality management.

In the context of API 5L welded pipe production, a certified QMS helps ensure that every step of the manufacturing process – from raw material procurement to final product testing – is conducted according to predetermined quality standards. This systematic approach is crucial in maintaining the high standards required for API 5L certification.

Moreover, a well-implemented QMS facilitates continuous improvement. By regularly reviewing and analyzing quality data, manufacturers can identify areas for enhancement, leading to more efficient processes and higher quality products over time.

For customers, dealing with a QMS-certified manufacturer of API 5L welded pipes offers several advantages:

- Increased confidence in product quality and consistency

- Reduced need for incoming quality inspections

- Potential for long-term cost savings due to fewer quality-related issues

- Assurance of regulatory compliance

In essence, QMS certification acts as a bridge between the specific requirements of API 5L and the broader quality management principles of ISO standards. It ensures that the manufacturer not only produces pipes that meet API 5L specifications but also does so within a framework of continuous improvement and customer focus.

About Longma Group

The standards for welded pipes are comprehensive and stringent. API 5L certification ensures that pipes meet specific industry requirements for oil and gas transportation. ISO certification broadens this quality assurance to encompass overall management systems, while QMS certification provides a structured approach to maintaining and improving quality across all aspects of production.

For manufacturers, adhering to these standards is not just about compliance – it's about commitment to quality, safety, and customer satisfaction. For customers, these certifications offer peace of mind, knowing that the welded pipes they're using meet the highest industry standards.

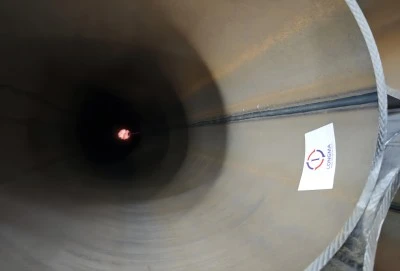

Longma Group Limited, a leading Chinese ERW/LSAW steel pipe manufacturer since 2003, is your ideal partner. With an annual output surpassing 1000000 tons by the end of 2023, we offer a wide range of API 5L welded pipes. Our products cover Grades B, X42, X46, X52, X56, X60, X65, X70, X80, with Welding Types including ERW, LSAW, DSAW, and SSAW. The Outer Diameter ranges from 3" to 80", and the thickness from SCH10 to SCH160, backed by API 5L Certificate, ISO Certificate, and QMS Certificate to ensure premium quality. Don't hesitate to contact us at info@longma-group.com for your 5L welded pipe needs!