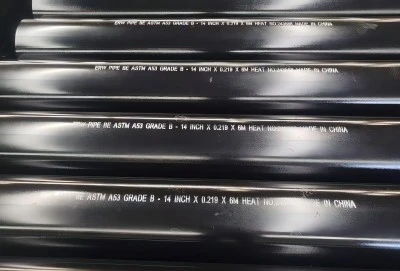

ASTM A53 is the standard specification for steel pipe used in various industries, including oil and gas, water supply, and construction. This specification covers seamless and welded black and hot-dipped galvanized steel pipe. ASTM A53 ERW pipe, manufactured using the Electric Resistance Welding (ERW) process, is particularly popular due to its cost-effectiveness and reliable performance. The standard outlines specific requirements for chemical composition, mechanical properties, and dimensional tolerances, ensuring consistent quality across different manufacturers.

|

|

|

ASTM A53: Scope and Applications

A53 pipe grades and types for diverse industriesASTM A53 pipes are available in two grades: Grade A and Grade B. Grade B is more commonly used due to its higher strength and wider range of applications. These pipes come in three types: Type F (furnace-welded), Type E (ERW), and Type S (seamless). Each type serves specific purposes across various industries.

In the oil and gas sector, ASTM A53 pipes are extensively used for transporting crude oil, natural gas, and refined products. Their durability and resistance to high pressures make them ideal for long-distance pipelines and offshore platforms. The construction industry relies on these pipes for structural applications, such as building frameworks and support systems.

Water supply systems benefit from the corrosion resistance of hot-dipped galvanized ASTM A53 pipes, ensuring clean water delivery. In industrial manufacturing, these pipes find applications in process piping, steam lines, and cooling systems. Bridge and building structures often incorporate ASTM A53 pipes for their strength and versatility.

Pressure and mechanical applications of ASTM A53

ASTM A53 pipes excel in high-pressure applications, making them suitable for hydraulic and pneumatic systems in various industries. Their ability to withstand internal pressures up to 2,500 psi (depending on size and grade) ensures reliable performance in demanding environments. The pipes' mechanical properties, including yield strength and tensile strength, contribute to their structural integrity in load-bearing applications.

In the petrochemical industry, ASTM A53 pipes handle corrosive fluids and gases, thanks to their chemical composition and surface treatments. The automotive sector uses these pipes in exhaust systems and fuel lines, leveraging their heat resistance and durability. HVAC systems in large buildings often incorporate ASTM A53 pipes for their thermal efficiency and longevity.

ASTM A53 vs. ASME SA53: Key differences explained

While ASTM A53 and ASME SA53 share many similarities, there are subtle differences between these specifications. ASME SA53 is essentially an adoption of ASTM A53 for use in pressure vessel applications. The main distinction lies in the additional requirements imposed by ASME for safety-critical applications.

ASME SA53 pipes undergo more rigorous testing and inspection procedures, particularly for non-destructive examination. The documentation and traceability requirements are more stringent for ASME SA53, ensuring a higher level of quality assurance. In terms of chemical composition and mechanical properties, the specifications are nearly identical, allowing for interchangeability in many applications.

Manufacturing Process Requirements for A53 Pipes

ERW vs. seamless: A53 pipe production methodsThe manufacturing process for ASTM A53 pipes varies depending on whether they are produced as ERW or seamless pipes. ERW pipes, including ASTM A53 ERW pipe, are made by rolling flat steel sheets into a cylindrical shape and welding the seam using electric resistance welding. This method is cost-effective and suitable for producing large quantities of pipes with consistent quality.

Seamless pipes, on the other hand, are manufactured by piercing a solid steel billet and then hot-rolling or cold-drawing it to the desired dimensions. While more expensive, seamless pipes offer superior strength and uniformity, making them preferred for high-pressure and critical applications.

The choice between ERW and seamless pipes depends on factors such as intended use, budget constraints, and specific project requirements. ERW pipes are often sufficient for general-purpose applications, while seamless pipes are chosen for more demanding environments.

Heat treatment and finishing processes for A53 pipes

After the initial forming process, ASTM A53 pipes undergo various heat treatment and finishing processes to enhance their properties and meet the standard's requirements. Normalizing, a heat treatment process, is commonly applied to improve the pipe's grain structure and mechanical properties. This process involves heating the pipe to a specific temperature and then allowing it to cool in air, resulting in a more uniform microstructure.

For enhanced corrosion resistance, many ASTM A53 pipes are hot-dip galvanized. This process involves immersing the pipes in molten zinc, creating a protective zinc coating that significantly extends the pipe's service life in corrosive environments. Some manufacturers offer additional surface treatments or coatings to further improve the pipes' performance in specific applications.

Quality control measures in ASTM A53 manufacturing

Manufacturers of ASTM A53 pipes implement rigorous quality control measures throughout the production process. These measures include regular inspections of raw materials, in-process checks during manufacturing, and final product testing. Advanced equipment, such as online ultrasonic flaw detectors and X-ray systems, are used to identify any defects or inconsistencies in the pipe walls.

Statistical process control techniques are employed to monitor and maintain consistent product quality. This involves tracking key parameters like dimensional tolerances, surface finish, and mechanical properties. By continuously analyzing this data, manufacturers can quickly identify and address any deviations from the standard specifications.

Testing and Certification of ASTM A53 Pipes

Mechanical and chemical testing for A53 complianceTo ensure compliance with ASTM A53 standards, pipes undergo a series of mechanical and chemical tests. Tensile testing is performed to verify the pipe's yield strength, tensile strength, and elongation properties. Flattening tests and bend tests assess the pipe's ductility and weld integrity.

Chemical analysis is conducted to confirm that the pipe's composition falls within the specified limits for elements such as carbon, manganese, phosphorus, and sulfur. This analysis is crucial for predicting the pipe's performance in various environments and applications.

Non-destructive examination techniques for A53 pipes

Non-destructive examination (NDE) plays a vital role in ensuring the quality and reliability of ASTM A53 pipes. Ultrasonic testing is widely used to detect internal defects, such as laminations or inclusions, without damaging the pipe. Electromagnetic testing methods, like eddy current testing, are employed to identify surface defects and variations in wall thickness.

For welded pipes, radiographic testing using X-rays or gamma rays is often performed to inspect the weld seam for any discontinuities or defects. These NDE techniques help manufacturers maintain high-quality standards and provide customers with confidence in the integrity of the pipes.

Certification and documentation requirements for A53 pipes

ASTM A53 pipes must be accompanied by proper certification and documentation to verify their compliance with the standard. This typically includes a mill test report (MTR) that details the chemical composition, mechanical properties, and test results for each batch of pipes. The MTR also provides traceability information, linking the pipes to their raw materials and manufacturing processes.

Additional certifications may be required for specific applications or industries. For example, pipes used in the oil and gas industry often need API (American Petroleum Institute) certification. These documents are essential for quality assurance and regulatory compliance in many projects.

ASTM A53 pipes play a crucial role in various industries due to their versatility, reliability, and cost-effectiveness. The standard specification ensures consistent quality and performance across different manufacturers and applications. From oil and gas transportation to water supply systems and structural support, these pipes continue to be a preferred choice for engineers and contractors worldwide. As industries evolve, the ASTM A53 standard adapts to meet new challenges, maintaining its relevance in the global market for steel pipes.

ASTM A53 Pipes Supplier

For high-quality ASTM A53 ERW pipe and other steel pipe products, Hebei Longma Group is a trusted manufacturer and supplier. With advanced production equipment imported from Germany and independently developed technologies, Hebei Longma ensures top-notch quality and efficiency. Their professional team of over 300 employees, including 60+ technical experts, guarantees expertise in every aspect of pipe manufacturing. Comprehensive testing facilities, including ultrasonic flaw detectors and X-ray systems, ensure rigorous quality control. With fast delivery times comparable to those of standard thickness pipes and a comprehensive range of certifications, Hebei Longma offers reliability and compliance. Their competitive pricing, backed by stable raw material partnerships and efficient production processes, makes them an excellent choice for your ASTM A53 pipe needs. To learn more or request a quote, contact us at info@longma-group.com.