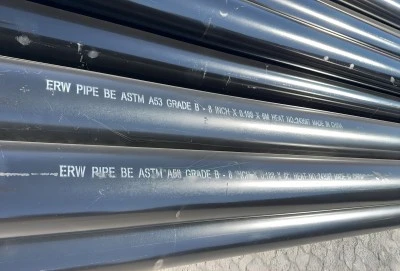

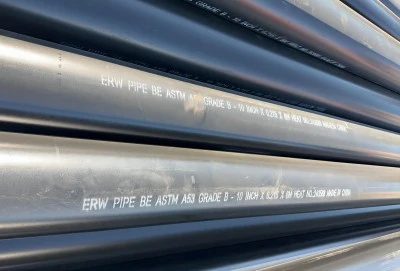

The tensile strength of ASTM A53 ERW pipe is a crucial factor in its performance and applications. For Grade A pipes, the minimum tensile strength is 48,000 psi (330 MPa), while Grade B pipes boast a higher minimum tensile strength of 60,000 psi (415 MPa). This robust tensile strength makes A53 ERW pipes ideal for various industrial applications, including oil and gas transportation, water supply systems, and structural support in construction projects.

|

|

|

Tensile Strength in Steel Pipes

Definition and Importance of Tensile Strength

Tensile strength is a fundamental property of steel pipes, measuring their resistance to breaking under tension. It's the maximum stress a material can withstand while being stretched before failing. For ASTM A53 ERW pipes, this property is paramount in ensuring the safety and reliability of piping systems across various industries.

In the context of industrial applications, tensile strength directly correlates with a pipe's ability to withstand internal pressure and external loads. Higher tensile strength typically indicates greater durability and longevity, making it a critical factor in selecting pipes for high-pressure or structurally demanding environments.

Testing Methods for A53 Pipe Tensile Strength

The tensile strength of ASTM A53 ERW pipes is determined through rigorous testing procedures. The most common method is the uniaxial tensile test, where a sample of the pipe material is subjected to increasing tension until it fails. This test provides valuable data on the pipe's yield strength, ultimate tensile strength, and elongation properties.

Advanced testing techniques may also include non-destructive methods such as ultrasonic testing or X-ray inspection. These methods allow for comprehensive evaluation of the pipe's structural integrity without compromising its usability.

Industry Standards for A53 Pipe Strength

ASTM International sets the standards for A53 pipe strength, ensuring consistency and reliability across manufacturers. These standards specify minimum tensile strength requirements for different grades of A53 pipes, taking into account factors such as manufacturing processes and intended applications.

Compliance with these standards is crucial for maintaining quality control and ensuring that pipes meet the necessary performance criteria for their intended use. Industries relying on A53 pipes, such as oil and gas or construction, often have additional specifications that build upon these base standards to meet specific project requirements.

Factors Affecting A53 Pipe Strength

Chemical Composition Impact on A53 Pipe StrengthThe chemical composition of ASTM A53 ERW pipes plays a significant role in determining their tensile strength. The primary alloying elements, including carbon, manganese, and trace amounts of other elements, contribute to the overall strength and durability of the pipe material.

Carbon content, in particular, has a substantial impact on tensile strength. Higher carbon levels generally result in increased strength but may reduce ductility. Manufacturers carefully balance these elements to achieve the optimal combination of strength and workability required for various applications.

Manufacturing Process Influence on Tensile Strength

The Electric Resistance Welding (ERW) process used in manufacturing A53 pipes significantly influences their tensile strength. This method involves high-frequency electric current to heat and fuse the edges of the steel strip, creating a strong, continuous weld seam.

The quality of the welding process, including factors such as heat input and cooling rates, directly affects the pipe's overall strength. Post-welding heat treatments may also be employed to enhance the mechanical properties of the welded area, ensuring uniform strength throughout the pipe.

Environmental Factors and A53 Pipe Performance

Environmental conditions can impact the long-term tensile strength and performance of ASTM A53 ERW pipes. Factors such as temperature fluctuations, exposure to corrosive substances, and mechanical stress can affect the pipe's structural integrity over time.

In harsh environments, such as offshore oil platforms or industrial processing plants, proper selection of pipe grades and appropriate protective measures are essential to maintain the pipe's tensile strength and overall performance throughout its service life.

A53 Pipe Grades: Strength Comparison

A53 Grade A vs Grade B Tensile StrengthASTM A53 pipes are available in two primary grades: Grade A and Grade B. The main difference between these grades lies in their tensile strength specifications. Grade A pipes have a minimum tensile strength of 48,000 psi (330 MPa), while Grade B pipes offer a higher minimum tensile strength of 60,000 psi (415 MPa).

This difference in tensile strength makes Grade B pipes more suitable for applications requiring higher pressure ratings or greater structural support. However, Grade A pipes remain a cost-effective option for less demanding applications, offering a balance between performance and economy.

A53 Pipe vs Other ASTM Standards: Strength Analysis

When comparing ASTM A53 ERW pipes to other ASTM standards, it's important to consider the specific requirements of each application. For instance, ASTM A106 seamless pipes often have higher strength ratings, making them suitable for high-temperature services. ASTM A500 structural tubing, on the other hand, may have different strength characteristics optimized for structural applications.

Understanding these differences allows engineers and project managers to select the most appropriate pipe standard for their specific needs, balancing factors such as strength, cost, and availability.

Selecting the Right A53 Grade for Your Project

Choosing the appropriate A53 pipe grade for a project involves considering multiple factors beyond just tensile strength. These include operating pressures, temperature ranges, and environmental conditions. For high-pressure applications or structurally critical components, Grade B pipes may be the preferred choice due to their higher strength ratings.

However, in less demanding scenarios, Grade A pipes might offer a more cost-effective solution without compromising safety or performance. Consulting with experienced engineers or suppliers can help in making informed decisions that align with project requirements and industry standards.

Understanding the tensile strength of ASTM A53 ERW pipes is crucial for ensuring the safety, efficiency, and longevity of piping systems across various industries. With Grade A offering a minimum tensile strength of 48,000 psi and Grade B boasting 60,000 psi, these pipes provide reliable solutions for a wide range of applications. By considering factors such as chemical composition, manufacturing processes, and environmental conditions, engineers and project managers can make informed decisions in selecting the right A53 pipe grade for their specific needs, ultimately contributing to the success and safety of their projects.

ASTM A53 ERW Pipes Manufacturer

When it comes to sourcing high-quality ASTM A53 ERW pipes, Hebei Longma Group stands out as a leading manufacturer and supplier. With advanced production equipment imported from Germany and independently developed technologies, Longma Group ensures top-notch quality in every pipe produced. Their professional team of over 300 employees, including 60+ technical personnel, guarantees expert handling of your orders.

Longma Group's comprehensive testing facilities, including online ultrasonic automatic flaw detectors and industrial X-ray television, ensure that every pipe meets the stringent ASTM A53 standards. With a fast delivery time of as little as 7 days for standard thickness pipes and a complete range of certifications including API 5L and ISO 9001, Longma Group offers both quality and reliability.

Thanks to long-term partnerships with raw material suppliers and an integrated production model, Longma Group maintains competitive pricing without compromising on quality. For more information or to place an order for A53 ERW pipes, contact us at info@longma-group.com.